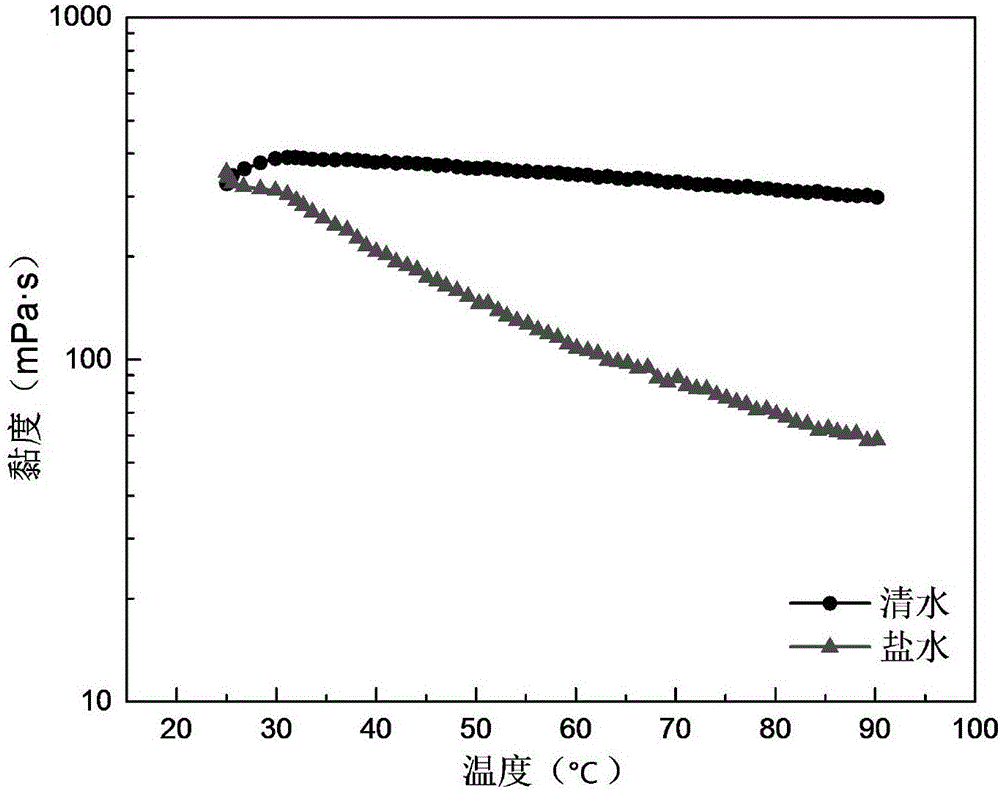

Anti-high-salinity comb-type micro-segmented hydrophobic associated polymer and preparation method thereof

A hydrophobic association, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large reduction in viscosity, low viscosity, and large reduction in viscosity, and achieve enhanced viscosity enhancement and wide application. Foreground, length increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

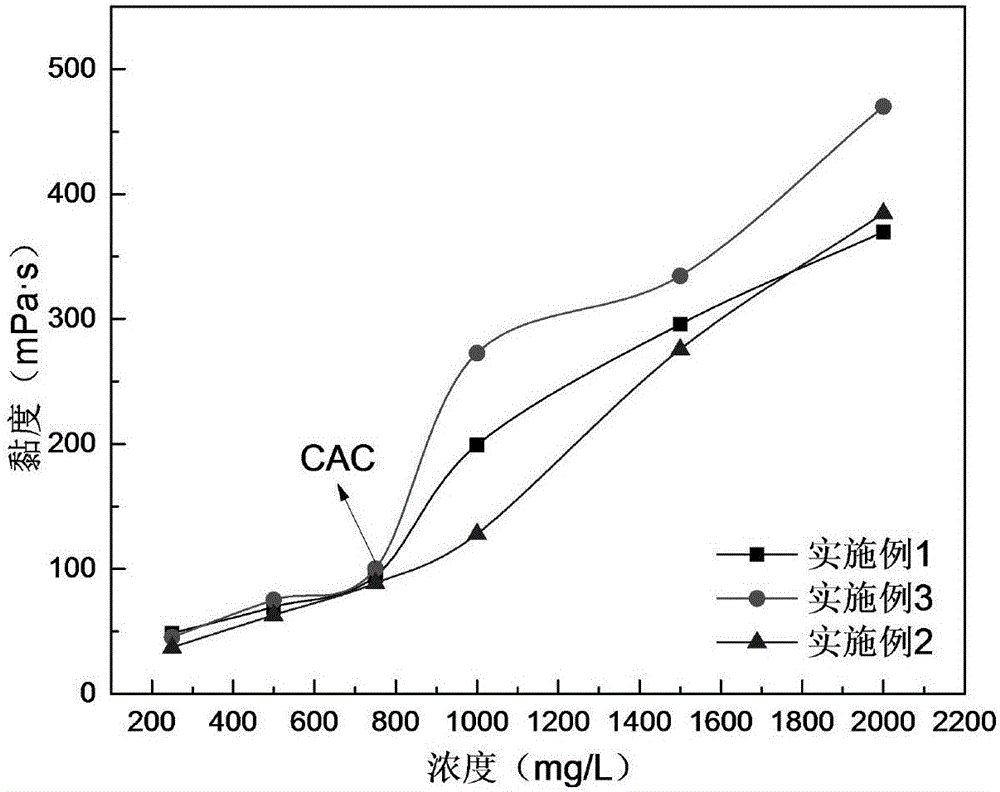

Embodiment 1

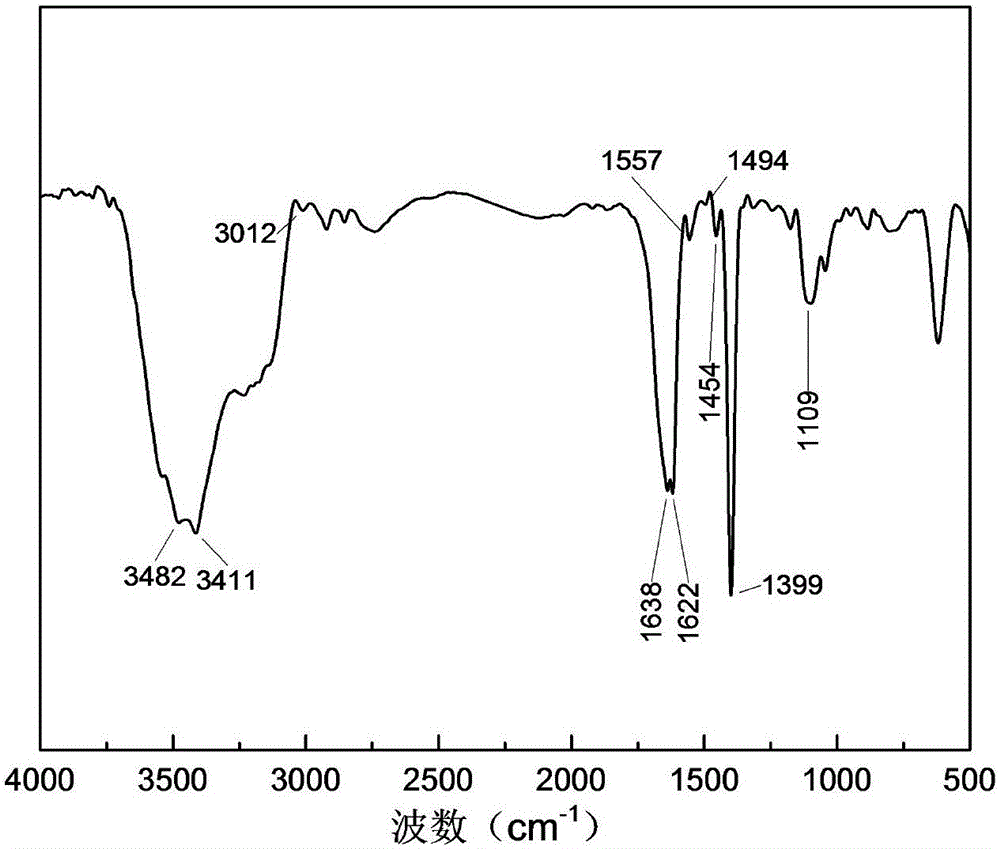

[0034] Preparation of a high-salt comb-type micro-block hydrophobic association polymer:

[0035] Weigh 10.625g of acrylamide (AM) and 1.875g of acrylic acid (AA), add distilled water and stir evenly, adjust the pH to 7; add 0.1g of N-phenylethyl-N-tetradecylmethacrylamide (PETMAM) , 0.4g nonionic surfactant monomer (b is 20), 0.01g cationic hydrophobic monomer (R number is 14) and 0.2g sodium dodecyl sulfate (SDS), add a certain amount of distilled water to make the solution volume reach 50mL, stir until the solution is clear and transparent; blow nitrogen gas for 15min to remove dissolved oxygen in the water; add initiator Irgacure 2959, place it under a photoinitiator, and react for 4h.

Embodiment 2

[0037] Weigh 8.75g of acrylamide (AM) and 3.75g of acrylic acid (AA), add distilled water and stir evenly, adjust the pH to 7; add 0.1g of N-phenylethyl-N-tetradecylmethacrylamide (PETMAM) , 0.4g nonionic surfactant monomer (b is 20), 0.01g cationic hydrophobic monomer (R number is 14) and 0.2g sodium dodecyl sulfate (SDS), add a certain amount of distilled water to make the solution volume reach 50mL, stir until the solution is clear and transparent; blow nitrogen gas for 15min to remove dissolved oxygen in the water; add initiator Irgacure 2959, place it under a photoinitiator, and react for 4h.

Embodiment 3

[0039]Weigh 10g of acrylamide (AM) and 2.5g of acrylic acid (AA), add distilled water and stir evenly, and adjust the pH value to 7; add 0.1g of N-phenylethyl-N-tetradecylmethacrylamide (PETMAM), 0.4g nonionic surfactant monomer (b is 20), 0.01g cationic hydrophobic monomer (R number is 14) and 0.2g sodium dodecyl sulfate (SDS), add a certain amount of distilled water to make the solution volume reach 50mL , stir until the solution is clear and transparent; pass nitrogen gas for 15 minutes to remove dissolved oxygen in water; add initiator Irgacure 2959, place it under a photoinitiator, and react for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com