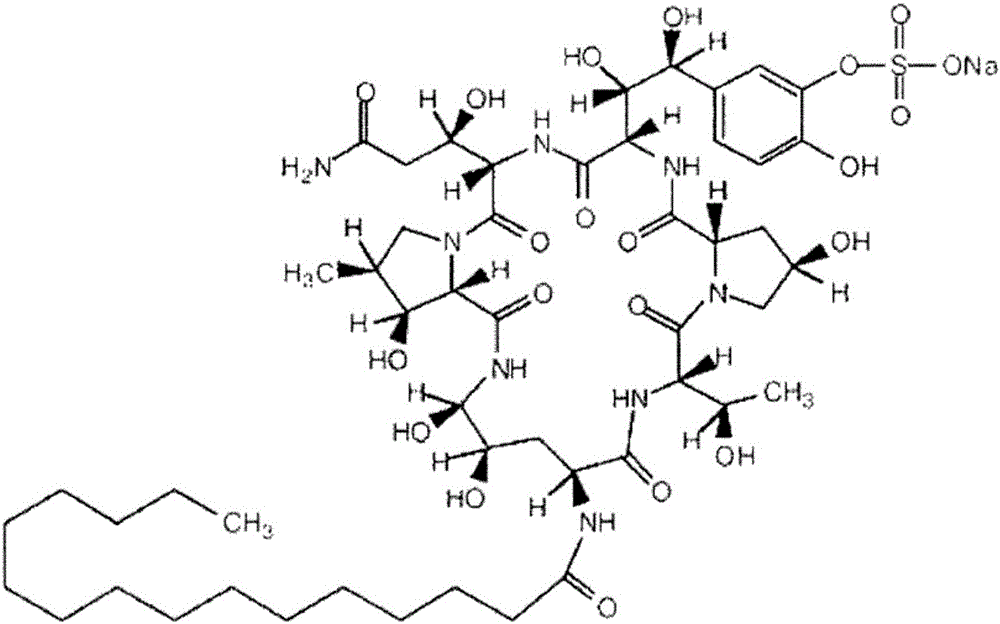

Preparation method of micafungin precursor

A technology of micafungin and precursor, which is applied in the field of preparation of micafungin precursor, can solve problems such as being not suitable for industrialized large-scale production, tedious operation steps of micafungin precursor, complicated preparation process and the like , to achieve the effect of stable method, good reproducibility and simple operation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the micafungin precursor comprises the following steps.

[0030] Step (1), take a small amount of micafungin precursor, ie FR179642 (ie WF11899A) producing spore suspension, inoculate it on the seed medium for cultivation. The components in the seed medium are (unit: g / L): glucose 15, glycerol 15, corn steep liquor powder 30, yeast powder 15, tryptone 15, sodium chloride 3, potassium dihydrogen phosphate 3, calcium carbonate 3 , and the balance is water. Incubate at 24°C for 2 days.

[0031] Step (2), inoculating the seed medium into the fermenter and adding the fermentation medium for fermentation. The components in the fermentation medium are (unit: g / L): glucose 15, sorbitol 90, corn steep liquor powder 10, soybean cake powder 30, triammonium citrate 4, ferrous sulfate heptahydrate 0.4, ammonium sulfate 4 , magnesium sulfate heptahydrate 3, calcium carbonate 5, dipotassium hydrogen phosphate 3, and the balance is water. Cultured at 28°C ...

Embodiment 2

[0038] The preparation method of the micafungin precursor comprises the following steps.

[0039] Step (1), take a small amount of micafungin precursor, ie FR179642 (ie WF11899A) producing spore suspension, and inoculate it on the seed medium for cultivation. The components in the seed medium components are (unit: g / L): 5 glucose, 5 glycerol, 10 corn steep liquor dry powder, 5 yeast powder, 5 tryptone, 1 sodium chloride, 1 potassium dihydrogen phosphate, carbonic acid Calcium 1, the balance is water. Cultured at 28°C for 4 days.

[0040]Step (2), inoculating the seed medium into the fermenter and adding the fermentation medium for fermentation. The components in the fermentation medium are (unit: g / L): glucose 5, sorbitol 70, corn steep liquor powder 6, soybean cake powder 20, triammonium citrate 2, ferrous sulfate heptahydrate 0.2, ammonium sulfate 2 , 1 magnesium sulfate heptahydrate, 3 calcium carbonate, 1 dipotassium hydrogen phosphate, and the balance is water. Cultur...

Embodiment 3

[0047] The preparation method of the micafungin precursor comprises the following steps.

[0048] Step (1), take a small amount of micafungin precursor, ie FR179642 (ie WF11899A) producing spore suspension, and inoculate it on the seed medium for cultivation. The components in the seed medium are (unit: g / L): glucose 10, glycerin 10, corn steep liquor powder 20, yeast powder 10, tryptone 10, sodium chloride 2, potassium dihydrogen phosphate 2, calcium carbonate 2 , and the balance is water. Cultured at 26°C for 3 days.

[0049] Step (2), inoculating the seed medium into the fermenter and adding the fermentation medium for fermentation. The components in the fermentation medium are (unit: g / L): glucose 10, sorbitol 80, corn steep liquor powder 8, soybean cake powder 25, triammonium citrate 3, ferrous sulfate heptahydrate 0.3, ammonium sulfate 3 , magnesium sulfate heptahydrate 2, calcium carbonate 4, dipotassium hydrogen phosphate 2, and the balance is water. Cultured at 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com