Method for simultaneous and integrated electric energy outputting by solar cell fabric unit and friction nano generator

A technology of nano generators and solar cells, applied in friction generators, photovoltaic power generation, electrolytic capacitors, etc., can solve the problems of large output impedance, weakened performance output, TENG short circuit, etc., and achieve the effect of easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

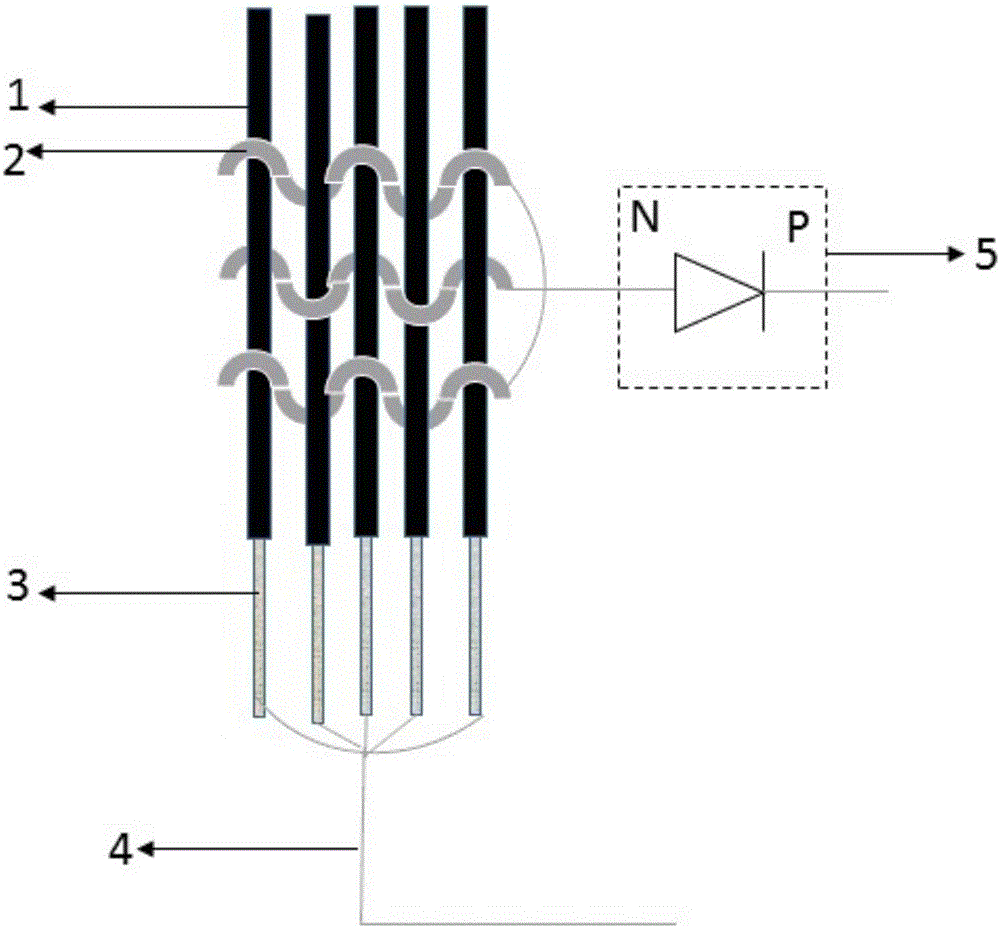

[0046] Example 1 Parallel connection of solar cell fabric and double-layer triboelectric nanogenerator

[0047] 1: Fabrication of solar fabric

[0048] (1) Choose polished and cleaned copper wire (200 microns in diameter) or polymer modified by electroless copper plating as the substrate, obtain Cu / Mn composite metal fibers by wet electroplating, and then grow and oxidize by hydrothermal The process of zinc, dye soaking and CuI coating prepares the photoanode of the solar cell.

[0049] (2) By means of ion sputtering, the copper wire (0.2 mm in diameter) is plated with gold to obtain Cu / Au composite metal fibers, and the thickness of the gold layer is between 100 nm.

[0050] (3) Select Cu / Au composite metal fibers as the warp of the fabric, and keep the distance between the metal fibers at 1mm. The photoanode of the solar cell is pulled by other fibers as the weft of the fabric. The solar cell fabric can be obtained by weaving the warp and weft in plain weave in an interlac...

Embodiment 2

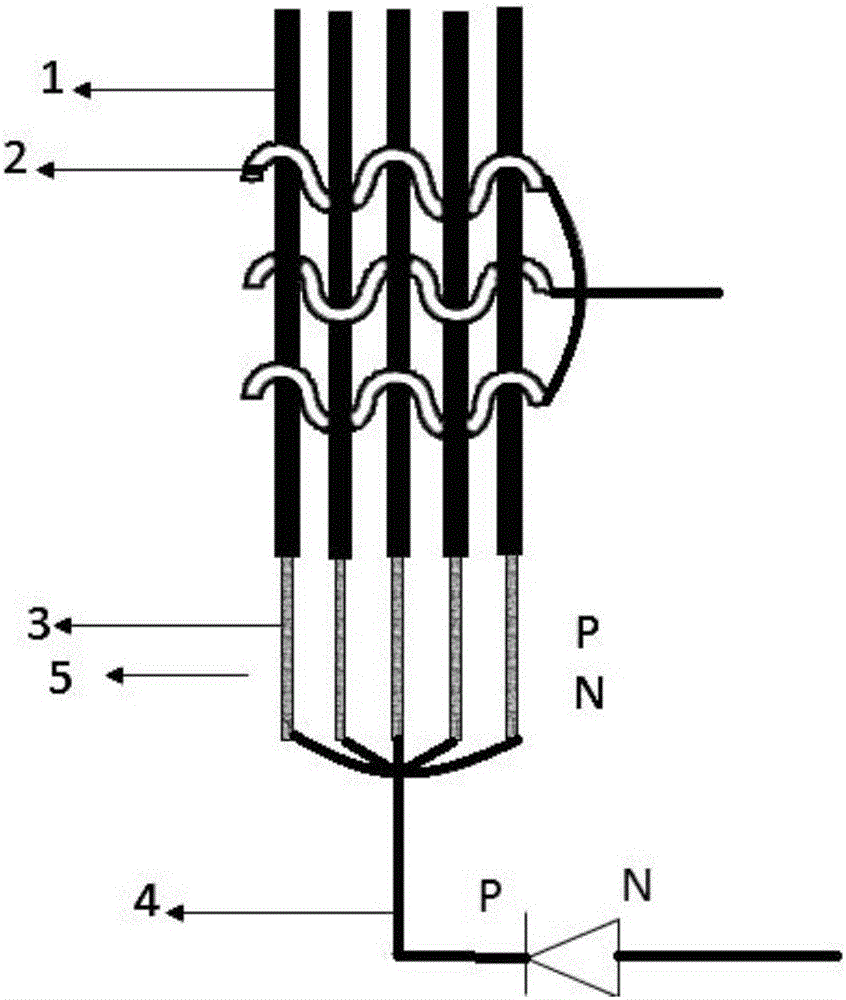

[0058] Example 2 Parallel connection of solar cell fabric and double-layer triboelectric nanogenerator

[0059] 1: Fabrication of solar fabric

[0060] (1) Select polished and cleaned copper wires (200 microns in diameter) or polymers modified by electroless copper plating as substrates, and obtain Cu / Mn composite metal fibers and Cu / Mn composite metal fibers by wet electroplating. The fibers are sintered to form a dense layer of zinc oxide with a thickness of 500nm. Coating a perovskite layer at 100°C, the thickness of the perovskite layer is 500nm, and then forming an electron transport layer with a thickness of 200nm on the surface of the perovskite layer at room temperature, that is, the photoanode of the perovskite battery

[0061] (2) By means of ion sputtering, the copper wire (0.2 mm in diameter) is plated with gold to obtain Cu / Au composite metal fibers, and the thickness of the gold layer is between 100 nm.

[0062] (3) Select Cu / Au composite metal fibers as the wa...

Embodiment 3

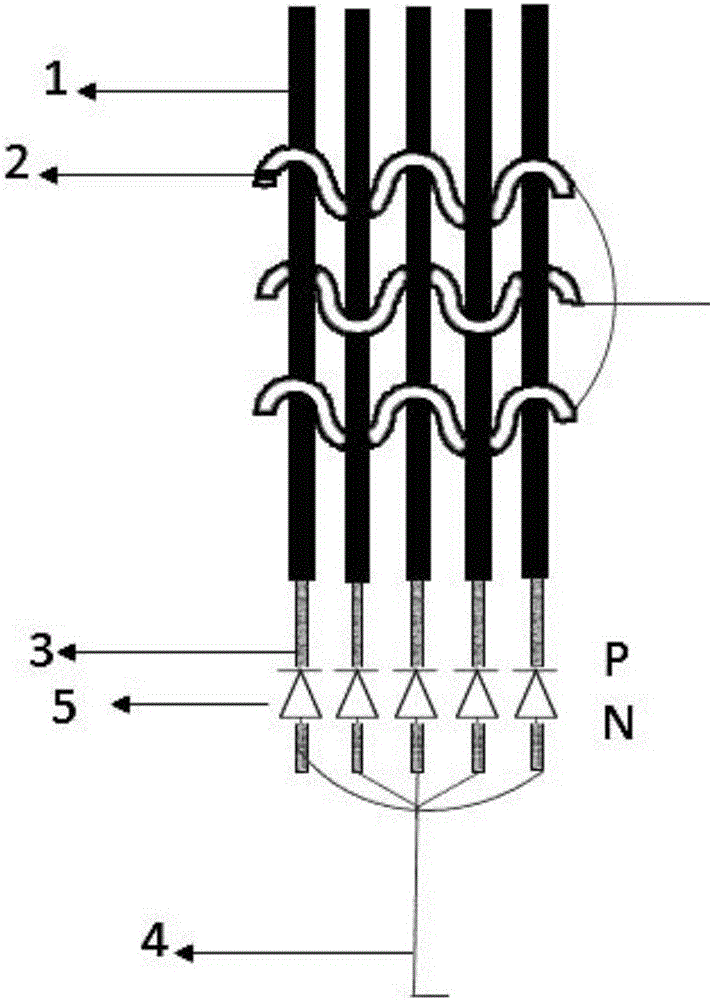

[0070] Example 3 Parallel connection of solar cell fabric and double-layer triboelectric nanogenerator

[0071] 1: Fabrication of solar fabric

[0072] (1) Choose polished and cleaned copper wire (200 microns in diameter) or polymer modified by electroless copper plating as the substrate, obtain Cu / Mn composite metal fibers by wet electroplating, and then grow and oxidize by hydrothermal The process of zinc, dye soaking and CuI coating prepares the photoanode of the solar cell.

[0073] (2) By means of ion sputtering, the copper wire (0.2 mm in diameter) is plated with gold to obtain Cu / Au composite metal fibers, and the thickness of the gold layer is between 100 nm.

[0074] (3) Select Cu / Au composite metal fibers as the warp of the fabric, and keep the distance between the metal fibers at 1mm. The photoanode of the solar cell is pulled by other fibers as the weft of the fabric. The solar cell fabric can be obtained by weaving the warp and weft in plain weave in an interlaced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com