Potato bread and production method thereof

A production method and potato technology, which are applied in the field of potato bread and its production, can solve the problems of low added value, environmental pollution, and the inability to retain the nutritional value of potatoes to the greatest extent, so as to achieve improved added value, unique taste and good market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

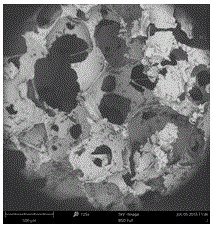

Image

Examples

Embodiment 1

[0036] The potato bread in Example 1 of the present invention is mainly made of the following raw materials in parts by weight: 10 parts of gluten powder, 10 parts of high-gluten flour, 30 parts of potato starch, 15 parts of potato fiber, 25 parts of water, 10 parts of sugar, and 2 parts of milk powder. 0.5 parts of salt, 10 parts of solid fat, 5 parts of whole egg liquid, 0.5 parts of yeast and 0.5 parts of compound emulsifier. Wherein the composite emulsifier includes raw materials in the following weight ratio, sucrose sugar ester: monoglyceride laurate = 1:2.

[0037] The processing method of potato bread in the embodiment of the present invention 1 comprises the following steps:

[0038] 1) Potato processing

[0039] A. Potato pulp preparation: select fresh, non-germinated, and non-scarred potatoes, wash and peel them, first wash with 0.3% citric acid aqueous solution, and then use a fruit and vegetable crusher to beat for 2 to 2 times, and filter the potato pulp throug...

Embodiment 2

[0054] The potato bread in Example 1 of the present invention is mainly made of the following raw materials in parts by weight: 14 parts of gluten powder, 18 parts of high-gluten flour, 48 parts of potato starch, 20 parts of potato fiber, 32.4 parts of water, 16 parts of sugar, and 5.6 parts of milk powder , 1.0 parts of salt, 12 parts of solid fat, 10 parts of whole egg liquid, 0.8 parts of yeast and 0.8 parts of compound emulsifier. Wherein the composite emulsifier includes raw materials in the following weight ratio, sucrose sugar ester: monoglyceride laurate = 1:2.

[0055] The processing method of potato bread in the embodiment of the present invention 1 comprises the following steps:

[0056] 1) Potato processing

[0057] A. Potato pulp preparation: select fresh, non-germinated, and non-scarred potatoes, wash and peel them, then wash them with 0.3% citric acid aqueous solution, and then beat them with a fruit and vegetable crusher for 2 to 3 times. The potato pulp is p...

Embodiment 3

[0071] The potato bread in Example 1 of the present invention is mainly made of the following raw materials in parts by weight: 20 parts of gluten powder, 20 parts of high-gluten flour, 50 parts of potato starch, 25 parts of potato fiber, 40 parts of water, 20 parts of sugar, and 8 parts of milk powder 1.5 parts of salt, 15 parts of solid fat, 15 parts of whole egg liquid, 1.0 part of yeast and 1.5 parts of compound emulsifier. Wherein the composite emulsifier includes the raw materials in the following weight ratio, sucrose sugar ester: monoglyceride laurate=1:2

[0072] The processing method of potato bread in the embodiment of the present invention 1 comprises the following steps:

[0073] 1) Potato processing

[0074] A. Potato pulp preparation: select fresh, non-germinated, and non-scarred potatoes, wash and peel them, then wash them with 0.3% citric acid aqueous solution, and then beat them with a fruit and vegetable crusher for 2 to 3 times. The potato pulp is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com