Preparation method and application of composite tobacco moisture retention agent

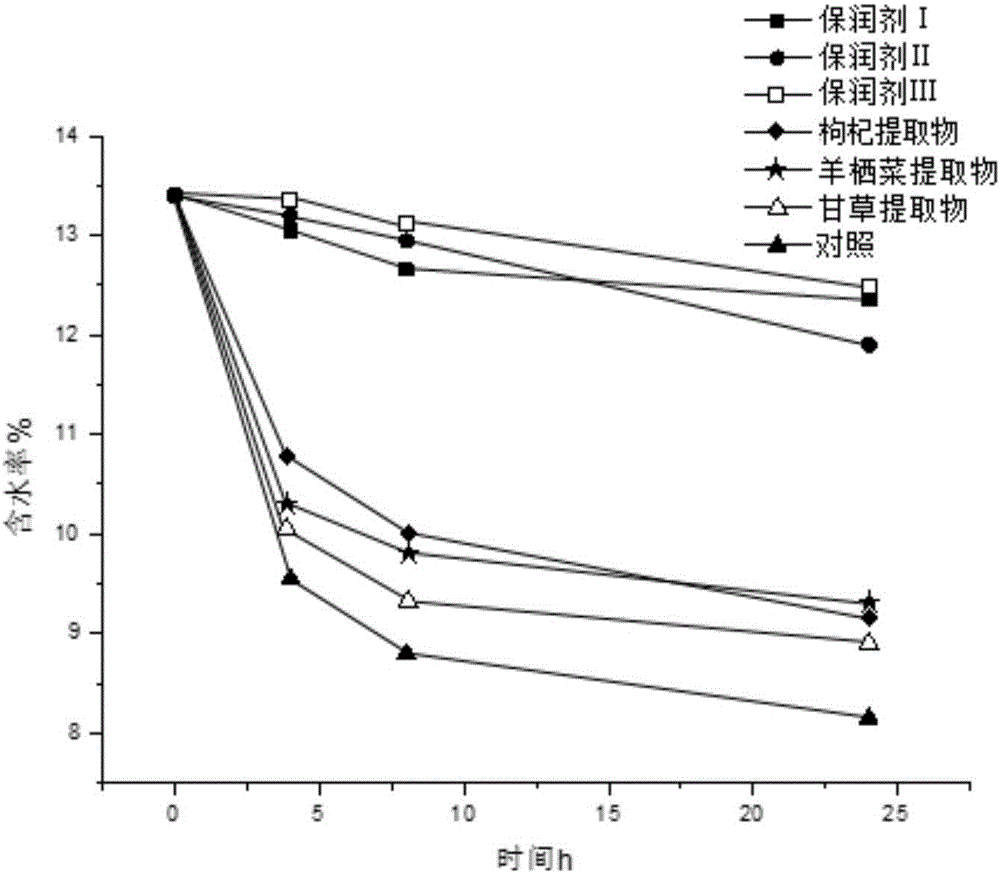

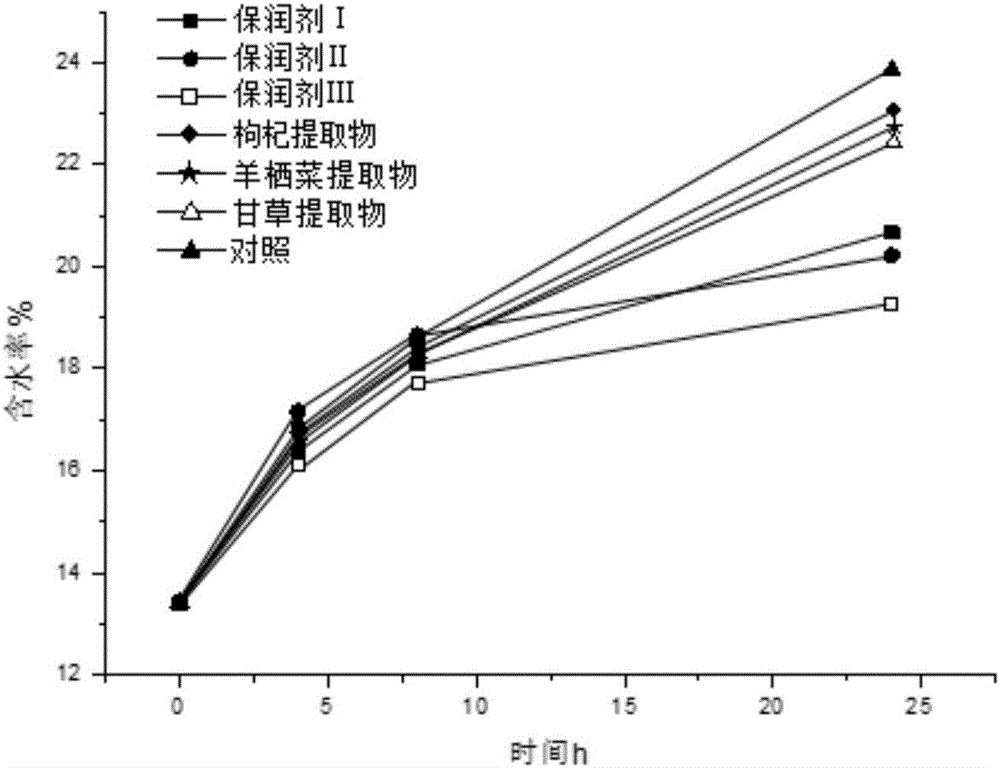

A compound and humectant technology, applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of rapid water dispersion, high irritation, and obvious dry feeling of shredded tobacco, achieve excellent results, improve moisture retention performance, and facilitate raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1000mg of tobacco humectant I, which contains 1mg of chitosan with a deacetylation degree of 70%, 3mg of caprylic glycerin and 1mg of propylene glycol.

[0024] making process:

[0025] (1) Preparation of natural plant mixed extracts. After cleaning the natural plant wolfberry, hijiki and licorice, dry them at 50°C and grind them, and mix the powders. The mass ratio of the mixture is wolfberry: hijiki: licorice = 1:5:1; at 90°C Under certain conditions, soak the powder in water for 3 hours, filter after soaking, concentrate the filtered filtrate to 1 / 10 of the volume of the original filtrate; then add ethanol to the concentrated solution and mix it at 4°C for 8 hours to continue concentrating, The precipitate is separated by centrifugation and filtration, and the precipitate is dried to obtain a natural plant mixed extract. Take by weighing 4 mg of the natural plant mixed extract for subsequent use;

[0026] (2) Accurately weigh 1 mg of chitosan, add 5 mg of acetic a...

Embodiment 2

[0033] 1000 mg of tobacco humectant II, which contains 1.7 mg of chitosan with a deacetylation degree of 80%, 4 mg of monoglyceride and 1.5 mg of glycerol.

[0034] making process:

[0035] (1) Preparation of natural plant mixed extracts. After cleaning the natural plant wolfberry, hijiki and licorice, dry them at 45°C, grind them, and mix the powders. The mass ratio of the mixture is wolfberry: hijiki: licorice = 1:7:1; Under certain conditions, soak the powder in water for 5 hours, filter after soaking, concentrate the filtered filtrate to 1 / 10 of the volume of the original filtrate; then add ethanol to the concentrated solution and mix it at 4°C for 8 hours to continue concentrating, The precipitate is separated by centrifugation and filtration, and the precipitate is dried to obtain a natural plant mixed extract. Take by weighing 5 mg of the natural plant mixed extract for subsequent use;

[0036](2) Accurately weigh 1.7 mg of chitosan, add 8.5 mg of acetic acid to diss...

Embodiment 3

[0042] 1000 mg of tobacco humectant III, which contains 2 mg of chitosan with a deacetylation degree of 90%, 6 mg of corn oil and 2 mg of sorbitol.

[0043] making process:

[0044] (1) Preparation of natural plant mixed extracts. After cleaning the natural plant wolfberry, hijiki and licorice, dry them at 60°C and grind them, and mix the powders. The mass ratio of the mixture is wolfberry: hijiki: licorice = 1:10:1; at 85°C Under certain conditions, soak the powder in water for 8 hours, filter after soaking, concentrate the filtered filtrate to 1 / 10 of the volume of the original filtrate; then add ethanol to the concentrated solution and mix it at 4°C for 8 hours to continue concentrating, The precipitate is separated by centrifugation and filtration, and the precipitate is dried to obtain a natural plant mixed extract. Take by weighing 6 mg of the natural plant mixed extract for subsequent use;

[0045] (2) Accurately weigh 2 mg of chitosan, add 10 mg of acetic acid to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com