Method and device of removing SO2 in flue gas by acid-ammonia method

A technology of SO2 and flue gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of slow ammonium sulfite oxidation speed, little use value of by-products, limited use of ammonia method, etc., and achieve saving Effects of equipment cost, time cost reduction, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

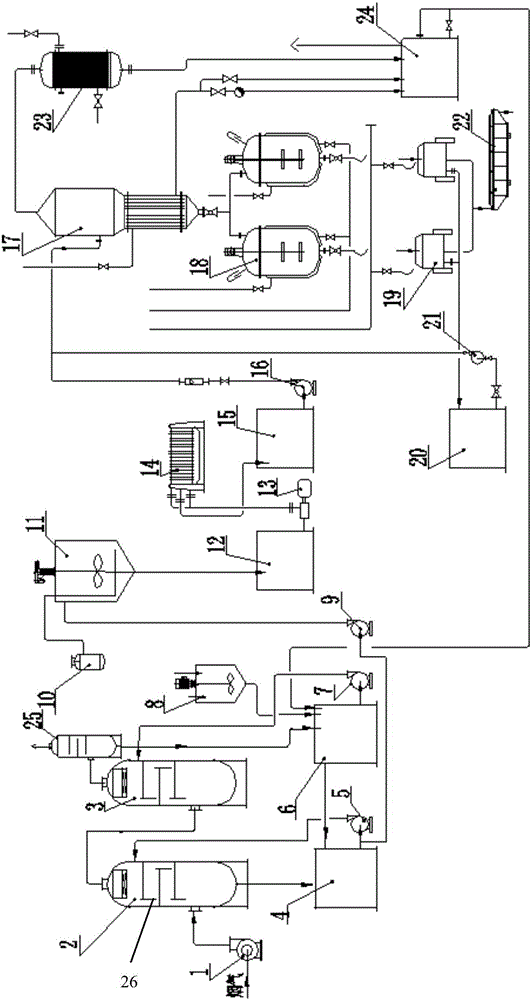

[0045] An Acid-Ammonia Method for Removing SO from Flue Gas 2 The device, the reaction device includes a blower for blowing flue gas, H connected to the blower 2 SO 4 Reaction equipment, neutralization reaction equipment, ammonium sulfate crystallization treatment equipment, water recycling equipment, the H 2 SO 4 Between the reaction equipment and the neutralization reaction equipment, between the neutralization reaction equipment and the ammonium sulfate crystallization treatment equipment, between the ammonium sulfate crystallization treatment equipment and the water circulation recovery equipment, between the water circulation recovery equipment and the H 2 SO 4 The reaction devices are connected by pipelines and pumps.

[0046] The H 2 SO 4 The reaction equipment comprises the first foam reaction tower 2 and the second foam reaction tower 3 connected in series, the first sulfuric acid storage tank 4, the first circulation pump 5, the second sulfuric acid storage tan...

Embodiment 2

[0052] Utilize the device that embodiment 1 provides to remove SO in flue gas 2 ;Anode calcining flue gas volume: 60000Nm 3 / h, SO 2 Concentration: 3000mg / Nm 3 , pressurized by the pressure blower 1, the flue gas enters the foam tower 2 connected in series in the first stage, and the foam tower 3 connected in series in the second stage. Contact with acid solution to remove SO in sulfuric acid tail gas 2 , the purified flue gas passes through the demister 25 in the tower to remove mist droplets, and the purified flue gas after demisting is emptied by the chimney.

[0053] Manganese sulfate is added in the second dilute acid storage tank 6 in the mode of dropping after being dissolved by catalyst dissolving tank 8, is sent to the top of secondary foam tower 3 by the second circulating pump 7, and manganese sulfate solution flows from the aperture of reaction plate to Downflow absorbs SO 2 , to absorb SO 2 Finally, dilute acid (sulfuric acid) is obtained and enters the seco...

Embodiment 3

[0064] On the basis of Example 1, the two-stage series foam reaction tower is changed to the first-stage foam reaction tower, the flue gas volume of the aluminum electrolytic cell: 108000Nm 3 / h,SO 2 Concentration: 400mg / Nm 3 , because SO 2The concentration is low, and the first-stage desulfurization process is adopted. Pressurized by the pressurized blower 1, enters the first-stage foam tower 2 with a diameter of 3.8m, contacts with dilute acid solution containing catalyst from top to bottom, and removes SO in the sulfuric acid tail gas 2 , the purified flue gas is demistered in the tower to remove mist droplets, and the purified flue gas after demisting is emptied by the chimney, and the process parameters are the same as in Example 2. The flue gas is treated, SO 2 The removal rate is more than 85%. Compared with the existing technology, the energy consumption is saved by more than 30%, and the investment and operation cost is reduced by more than 20%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap