Method for improving corrosion resistance of cast iron casting

A corrosion-resistant, cast-iron technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of low corrosion resistance, casting wear, poor practicability, etc., to increase corrosion resistance, reasonable distribution of Cr elements, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

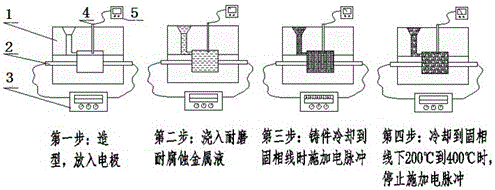

[0025] The method for improving the corrosion resistance of cast iron castings described in this embodiment, the composition and solid-liquid transition temperature of the samples processed in this embodiment are as shown in Table 1, and are numbered 1, 2, and 3 according to the composition, and specifically include the following steps:

[0026] (1) During the molding process, two nickel electrodes are embedded in the sand mold. The end of the nickel electrode is connected to the cavity of the sand mold, and the position is close to the working surface of the casting. The other end of the nickel electrode is connected to the electric pulse generator;

[0027] (2) Pour the melted three-component cast iron metal liquid into the sand mold at 40°C higher than the respective liquidus lines. The metal liquid connects the ends of the two electrodes to form a closed circuit. After pouring, the castings are cooled to their respective solid phases. Immediately apply a sharp wave electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com