Welding base plate and application of welding base plate to magnesium/aluminum dissimilar metal welding

A technology for welding backing plates and dissimilar metals, applied in the direction of welding/welding/cutting items, welding equipment, metal processing equipment, etc., to achieve the effects of reducing welding difficulty, improving mechanical strength, and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Automatic argon arc butt welding of rolled plates of AZ31 magnesium alloy and 6061 aluminum alloy on self-made fixtures:

[0033] (1) Both AZ31 magnesium alloy and 6061 aluminum alloy rolled plates have a thickness of 2mm and a size of 50×110mm. Before welding, use a steel brush to remove the surface oxide layer, and use acetone to remove surface grease and dirt;

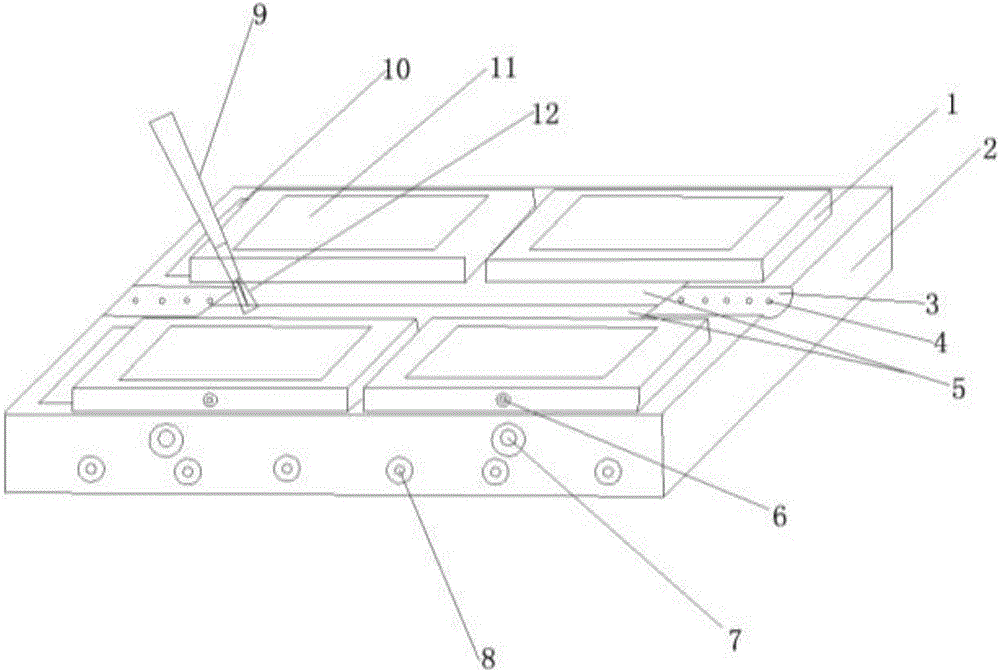

[0034] (2) Place the plate to be welded on the red copper lower backing plate, the welding fusion zone falls above the U-shaped groove, and then place the red copper upper backing plate symmetrically on both sides above it. The interior of the upper and lower backing plates of copper is pre-filled with an appropriate amount of liquid nitrogen before welding. The red copper backing plate is 15mm away from the welding fusion zone, and then clamped and fixed, so that the plates to be welded can be evenly stressed and deformation can be suppressed (such as figure 1 shown);

[0035] (3) if figure 1 As shown, bu...

Embodiment 2

[0038] Automatic argon arc butt welding of AZ31 magnesium alloy and 5052 aluminum alloy rolled plates on self-made fixtures:

[0039] (1) AZ31 magnesium alloy and 5052 aluminum alloy rolled plates have a thickness of 3mm and a size of 70×120mm. Before welding, the surface is removed with a steel brush to remove the surface oxide layer, and the surface grease and dirt are removed with acetone.

[0040] (2) Place the plate to be welded on the red copper lower backing plate, the welding fusion zone falls above the U-shaped groove, and then place the red copper upper backing plate symmetrically on both sides above it. The interior of the upper and lower backing plates of copper is pre-filled with an appropriate amount of liquid nitrogen before welding. The copper upper backing plate is 10mm away from the welding fusion zone, and then clamped and fixed, so that the plates to be welded can be evenly stressed and deformation can be suppressed (such as figure 1 shown);

[0041] (3) ...

Embodiment 3

[0044] Automatic argon arc butt welding of AZ80 magnesium alloy extruded plate and 6061 aluminum alloy rolled plate on self-made fixture:

[0045] (1) AZ80 magnesium alloy and 6061 aluminum alloy rolled plates have a thickness of 3.5mm and a size of 50×180mm. Before welding, steel brushes are used to remove the surface oxide layer, and acetone is used to remove surface grease and dirt.

[0046] (2) Place the plate to be welded on the red copper lower backing plate, the welding fusion zone falls above the U-shaped groove, and then place the red copper upper backing plate symmetrically on both sides above it. The interior of the upper and lower backing plates of copper is pre-filled with an appropriate amount of liquid nitrogen before welding. The copper upper backing plate is 10mm away from the welding fusion zone, and then clamped and fixed, so that the plates to be welded can be evenly stressed and deformation can be suppressed (such as figure 1 shown);

[0047] (3) if fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com