Preparation method of chromic oxide nano-material

A technology of chromium trioxide and nanomaterials, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of expensive alkoxides and unfavorable large-scale production, and achieve low preparation costs, easy operation control, and simple preparation process routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

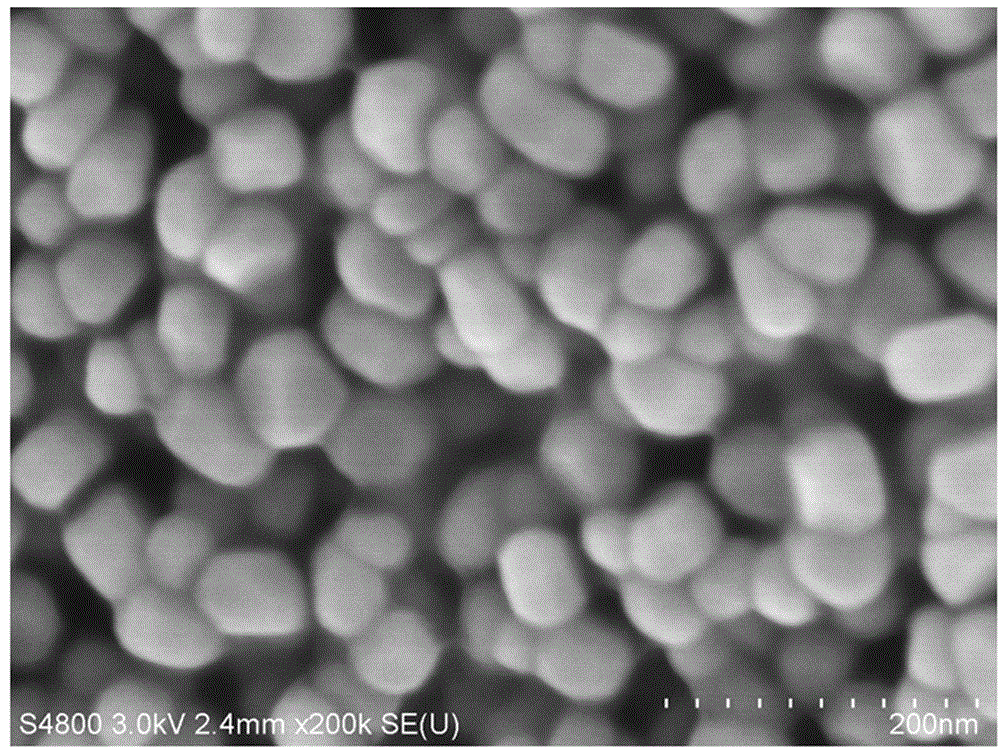

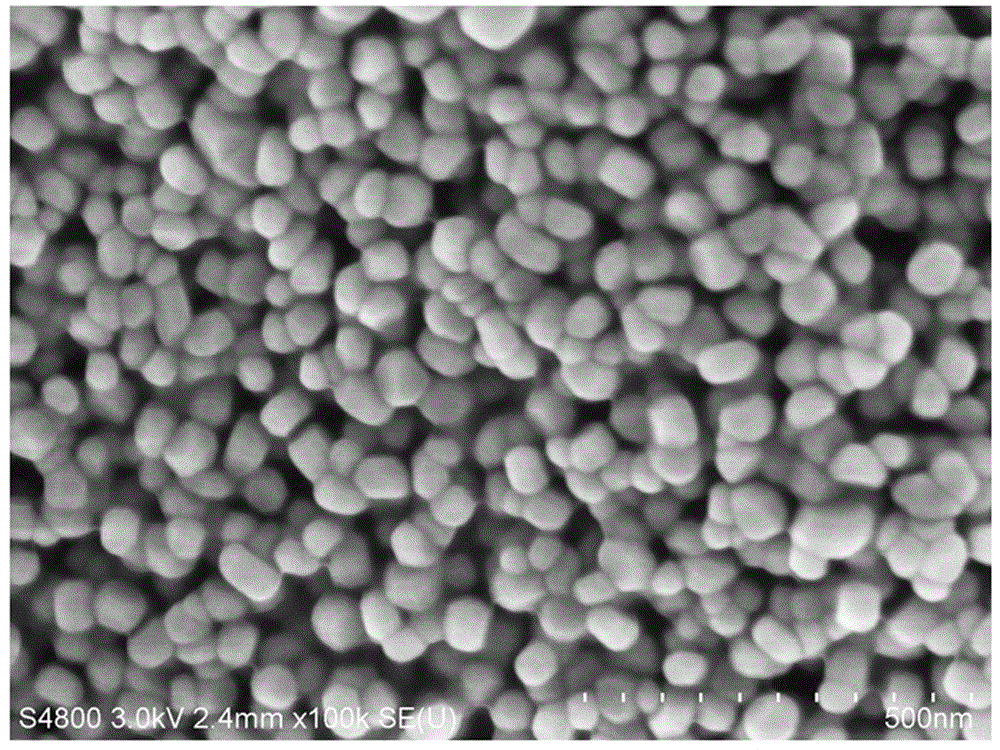

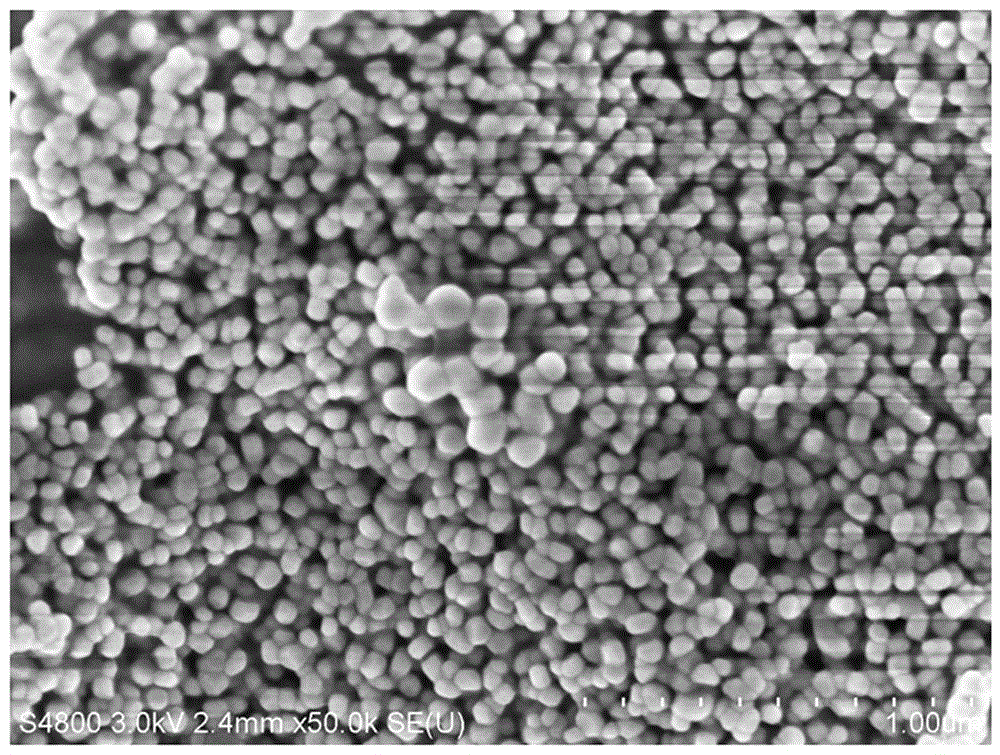

[0031] Accurately weigh chromium acetylacetonate and put it into methanol (12C, 99.95%), stir and dissolve, and prepare a methanol solution of chromium acetylacetonate with a molar concentration of 0.01mol / L. The methanol solution obtained is carried out solvothermal reaction, and the solvothermal reaction temperature is 220 ℃, and the solvothermal reaction time is 24 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 5°C / min, and dried at 100°C for 3 hours. Then place it in a muffle furnace for calcination, the calcination time is 2 hours, the calcination temperature is 800 °C, and the heating rate is 10 °C / min. Chromium trioxide nanomaterials were obtained after natural cooling, with a size of 30 nm, and the yield of the product was 99.9%. The purity of the product is 99.98%, and the impurity carb...

Embodiment 2

[0033] Accurately weigh chromium acetylacetonate and put it into methanol (12C, 99.95%), stir and dissolve, and prepare a methanol solution of chromium acetylacetonate with a molar concentration of 0.02mol / L. The methanol solution obtained is carried out solvothermal reaction, and the solvothermal reaction temperature is 110 ℃, and the solvothermal reaction time is 48 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 5°C / min, and dried at 60°C for 5 hours. Then place it in a muffle furnace for calcination, the calcination time is 4 hours, the calcination temperature is 800 °C, and the heating rate is 20 °C / min. Chromium trioxide nanomaterials were obtained after natural cooling, with a size of 50 nm, and the yield of the product was 99.5%. The purity of the product is 99.95%, and the impurity carbo...

Embodiment 3

[0035] Accurately weigh chromium acetylacetonate and put it into methanol (12C, 99.95%), stir and dissolve, and prepare a methanol solution of chromium acetylacetonate with a molar concentration of 0.05mol / L. The methanol solution obtained is carried out solvothermal reaction, and the solvothermal reaction temperature is 200 ℃, and the solvothermal reaction time is 12 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 5°C / min, and dried at 120°C for 1 hour. Then place it in a muffle furnace for calcination, the calcination time is 6 hours, the calcination temperature is 800 °C, and the heating rate is 10 °C / min. Chromium trioxide nanomaterials were obtained after natural cooling, with a size of 40 nm, and the yield of the product was 99.6%. The purity of the product is 99.96%, and the impurity carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com