Sewage treatment efficient energy-saving pressure MBR (membrane bioreactor)

A bioreactor, high-efficiency and energy-saving technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc. problems such as large consumption, to achieve the effect of reducing volume, reducing energy consumption, reducing volume and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

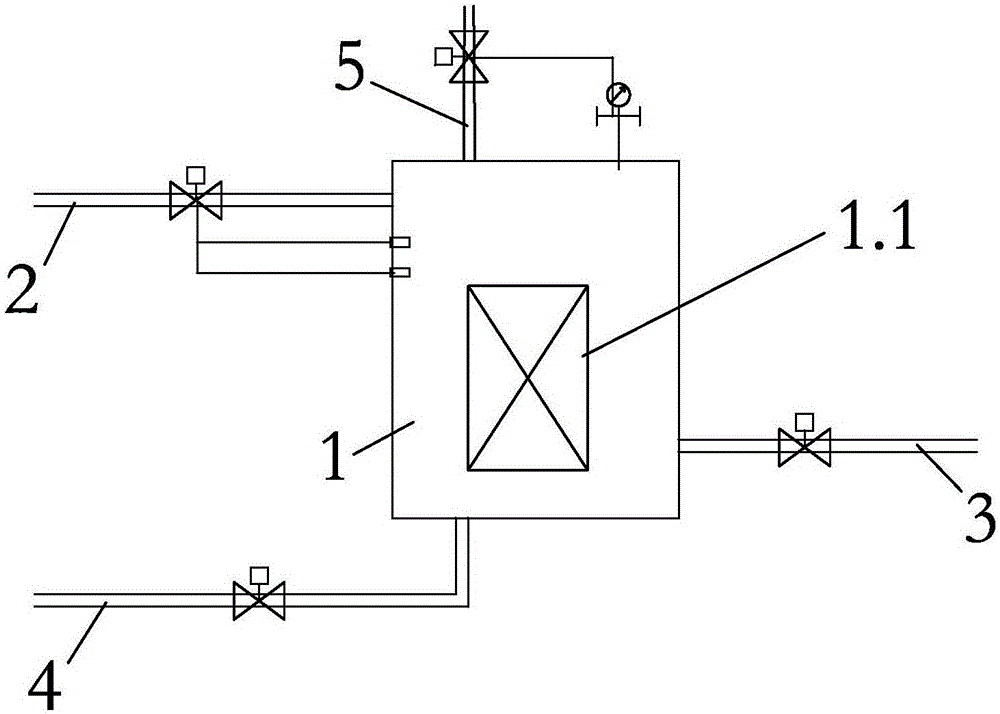

[0017] Embodiment 1: refer to attached figure 1 .

[0018] A high-efficiency and energy-saving pressure membrane bioreactor for sewage treatment, comprising a closed MBR reactor 1, a water inlet pipeline 2, a water outlet pipeline 3, an air inlet pipeline 4, and an exhaust pipeline 5; the MBR reactor 1 includes a biochemical Components and Membrane Modules 1.1;

[0019] Pass air or oxygen aeration into the MBR reactor 1 through the inlet pipeline 4, and form a certain pressure in the MBR reactor 1; use the pressure in the MBR reactor 1 to drive the sewage from the MBR reactor 1 through the outlet pipeline 3 discharge.

Embodiment 2

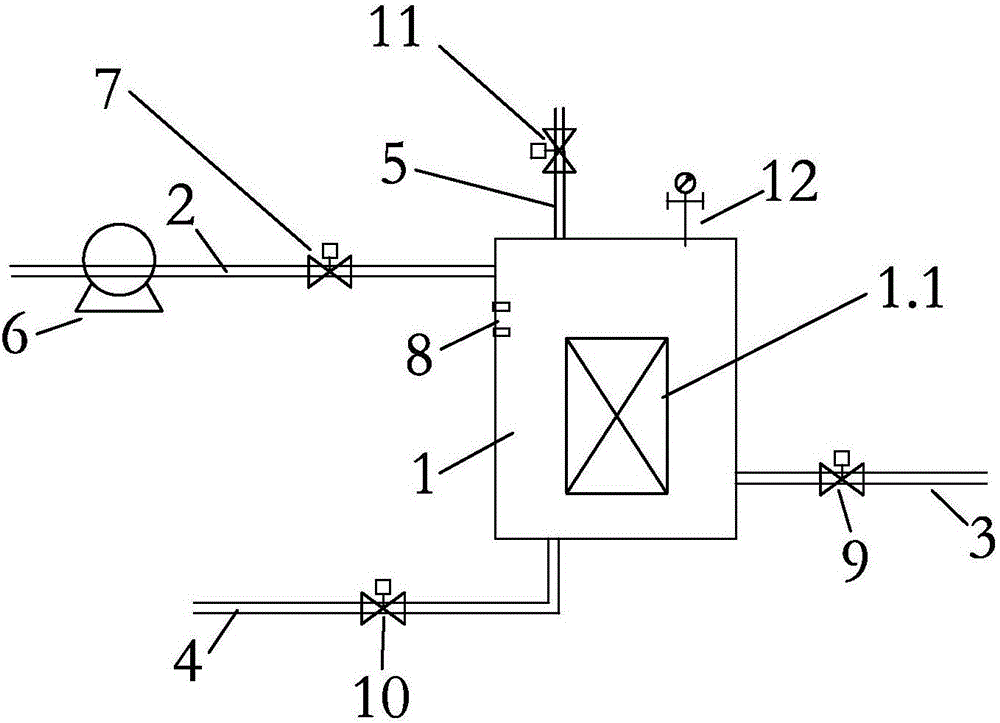

[0020] Embodiment 2: refer to attached figure 2 .

[0021] A water inlet pump 6, an electric control valve or a solenoid valve 7 is installed on the water inlet pipeline 2 of the system, and a water level sensor 8 is installed in the MBR reactor 1. The water level sensor 8 is used for monitoring the water level, and controls the water inlet pump 6, the electric control valve or the electromagnetic valve 7 according to the water level. When the water level is lower than the lower limit value, the electric control valve or electromagnetic valve 7 is opened, the water inlet pump 6 works, the system enters water, and the water level rises; when the water level rises to the upper limit value, the electric control valve or electromagnetic valve 7 is closed, and the water inlet pump 6 Stop working, the system stops water intake, and the water level begins to drop. Keep the water level between the set upper and lower limit water levels.

[0022] A valve 9 is set on the water outle...

Embodiment 3

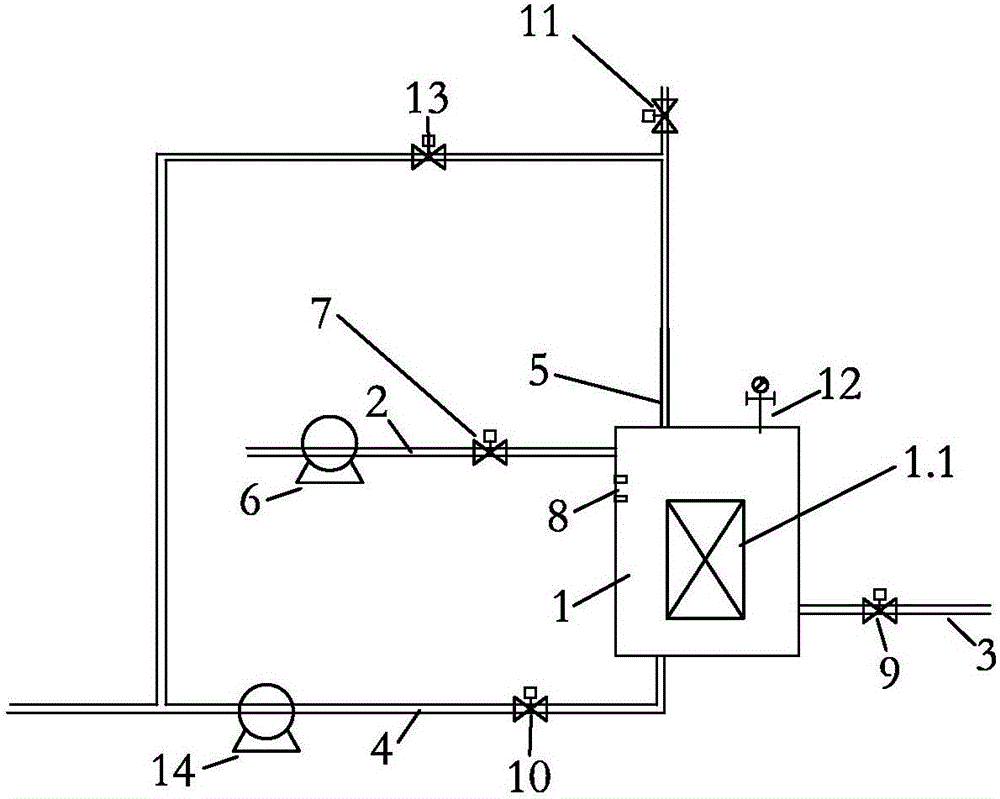

[0024] Embodiment 3: refer to attached image 3 .

[0025] On the basis of Embodiment 2, a residual gas circulation circuit is added, and a check valve 13 and a booster device 14 are arranged on the cycle circuit; driven by the booster device, the recycling of pressurized gas is realized. Minimize the discharge of residual pressure gas, thereby reducing energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com