Method for preparing fiber-loaded rutile type TiO2 composite SiO2 aerogel

A rutile-type, composite gel technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of high specific surface area of nanoparticles, difficulty of heat insulation engineering, and reduced heat insulation performance, etc., to achieve high near-infrared reflectivity , increase load uniformity, good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

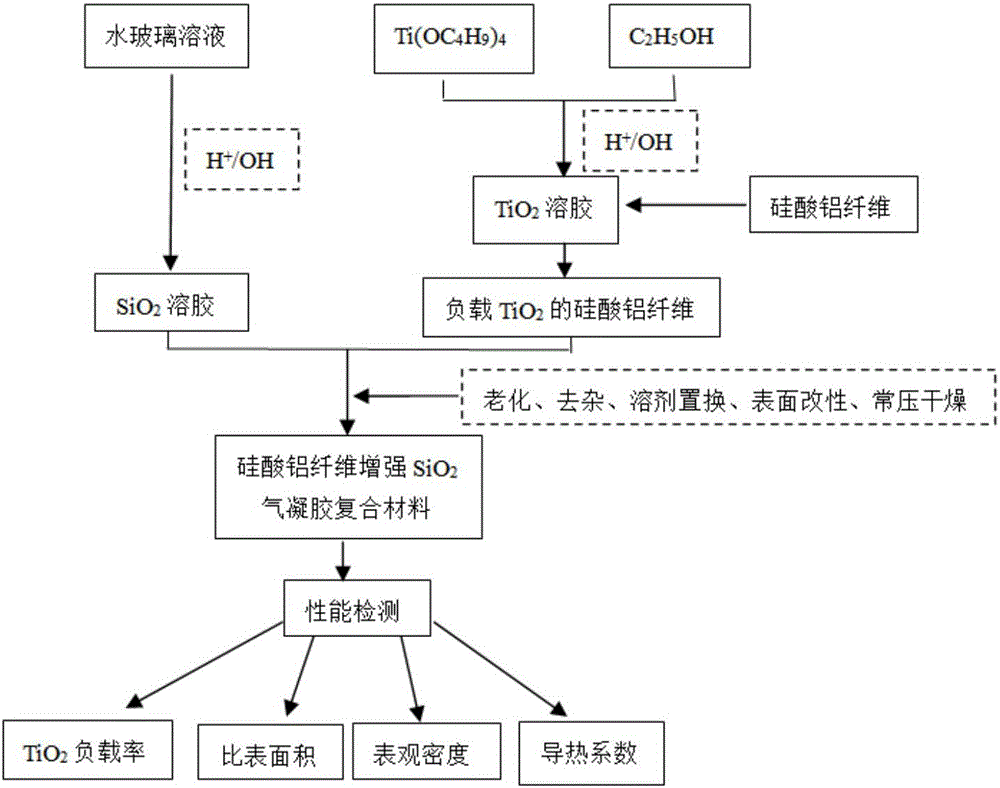

[0042] The invention provides a fiber-loaded rutile TiO with good mechanical properties and thermal insulation properties 2 Composite SiO 2 The preparation method of airgel, the composite airgel it prepares is used as thermal insulation material; Solve TiO 2 In SiO 2 Dispersion inhomogeneity and SiO in airgel composites 2 The thermal conductivity of airgel composites increases too fast in the near-infrared region.

[0043] In order to achieve the above purpose, the present invention uses piranha solution to carry out hydroxylation treatment on fiber to prepare TiO 2 sol; the hydroxylated fibers were impregnated in TiO 2 In the sol, TiO was loaded on the surface of the hydroxylated fiber by impregnation-pulling method 2 sol, and calcined at high temperature to obtain surface-loaded rutile TiO 2 fiber; preparation of SiO 2 sol, the surface will be loaded with rutile TiO 2 The fibers are impregnated in SiO 2 Sol, get SiO 2 Composite sol; SiO 2 Fiber-supported rutile Ti...

Embodiment 1

[0045] Embodiment 1: as Figure 1-7 As shown, the present invention provides a fiber-loaded rutile TiO 2 Composite SiO 2 The preparation method of airgel: wherein:

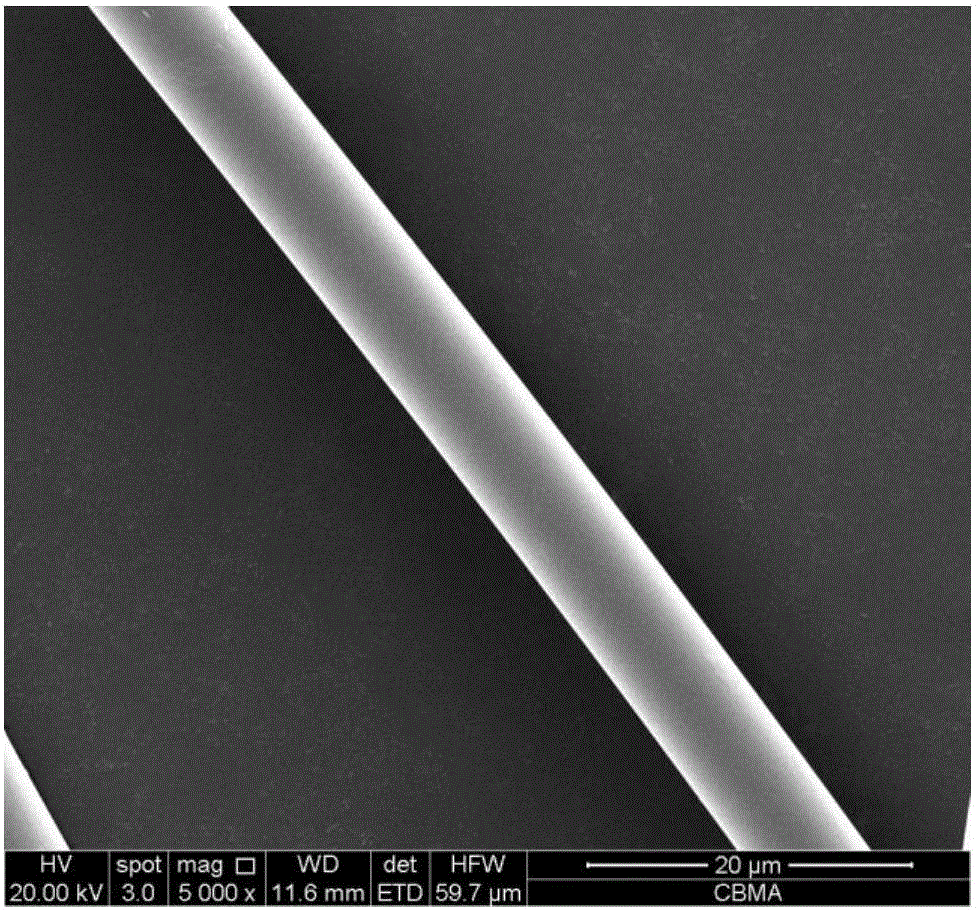

[0046] Take 30mL98%H 2 SO 4 and 10 mL of 30% H 2 o 2 Make "piranha solution", put 2.5g aluminum silicate fiber (or choose mullite fiber, quartz fiber, carbon fiber) into "piranha solution", etch for 30min, and then wash it with deionized water several times, Until the "piranha solution" is cleaned, then dry at 90°C for 10 hours to obtain hydroxylated aluminum silicate fibers on the surface;

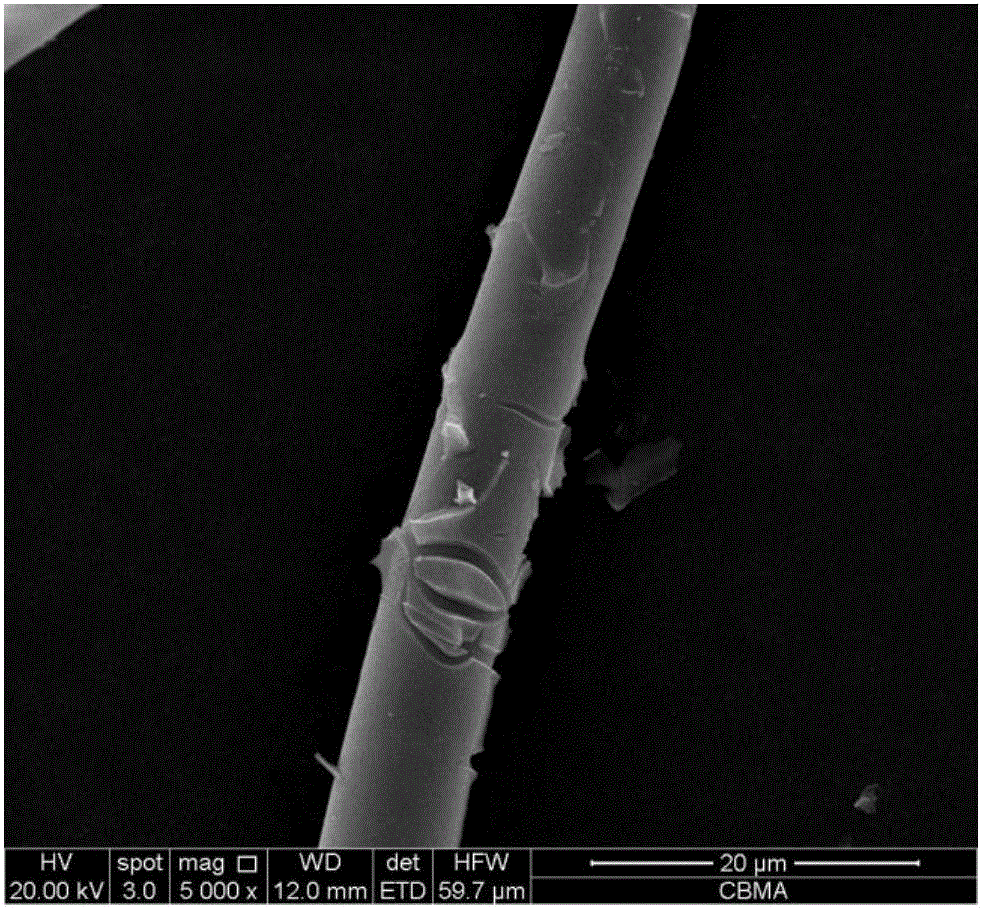

[0047] Mix butyl titanate, absolute ethanol, and deionized water at a volume ratio of 1:5:0.3, and stir to prepare stable TiO 2 sol, and then the hydroxylated aluminum silicate fibers were impregnated in TiO 2 In the sol, TiO was loaded on the surface of aluminum silicate fiber by impregnation-pulling method 2 sol, finally loaded with TiO 2 The aluminum silicate fiber of the sol is placed in a muffle furnace, calcin...

Embodiment 2

[0051] Embodiment 2: as Figure 1-7 As shown, the present invention provides a fiber-loaded rutile TiO 2 Composite SiO 2 The preparation method of airgel: wherein:

[0052] Take 30mL98%H 2 SO 4 and 10 mL of 30% H 2 o 2 Make "piranha solution", put 2.5g aluminum silicate fiber (or choose mullite fiber, quartz fiber, carbon fiber) into "piranha solution", etch for 60min, and then wash it with deionized water several times, Until the "piranha solution" is cleaned, and then dried at 90°C for 10 hours, the hydroxylated aluminum silicate fibers on the surface are obtained.

[0053] Mix butyl titanate, absolute ethanol, and deionized water at a volume ratio of 1:6:0.2, and stir to prepare stable TiO 2 sol, and then the hydroxylated aluminum silicate fibers were impregnated in TiO 2 In the sol, TiO was loaded on the surface of aluminum silicate fiber by impregnation-pulling method 2 sol, finally loaded with TiO 2 The aluminum silicate fibers of the sol are placed in a muffle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com