Methyl p-tolyl sulfone and preparation method

A technology of methylsulfonyltoluene and p-toluenesulfonyl chloride is applied in the fields of pesticides, raw material intermediates and preparation, medicine, veterinary drugs, and dyestuffs. The effect of pollution risk, reduction of raw material cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

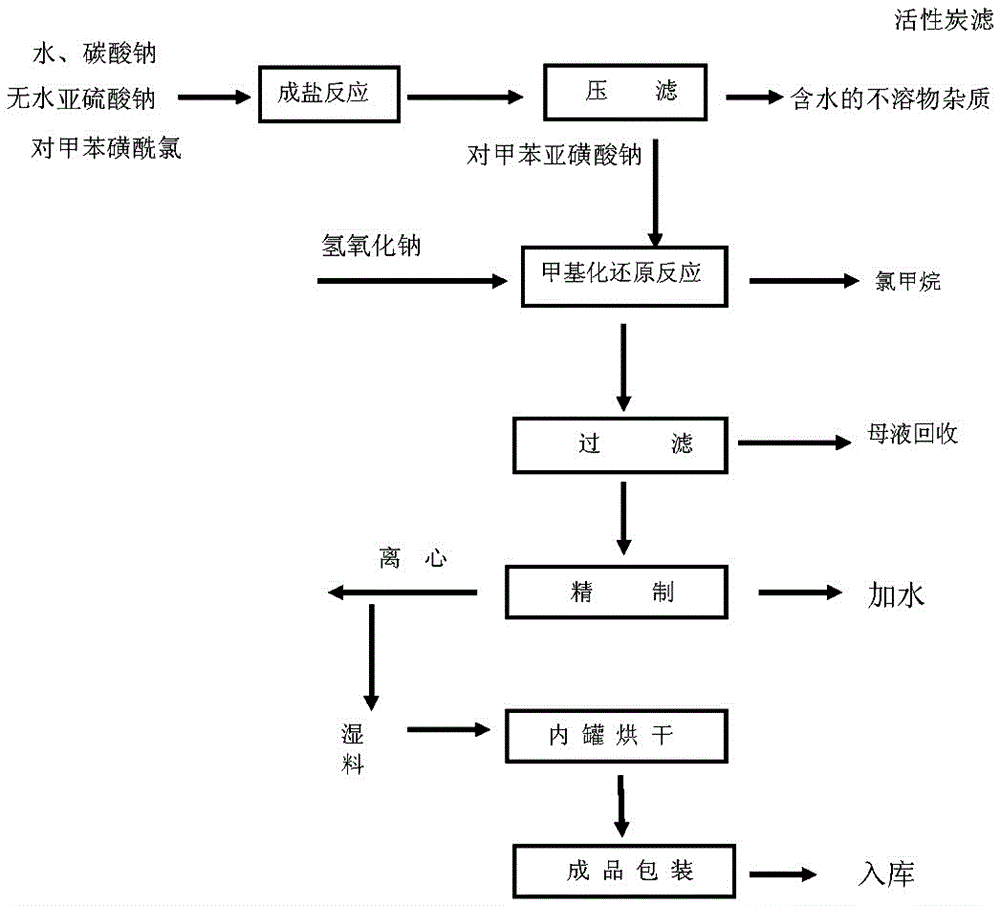

[0036] figure 1 Shown, a kind of p-thiamphenicol toluene preparation method of the present invention, described preparation method comprises the steps:

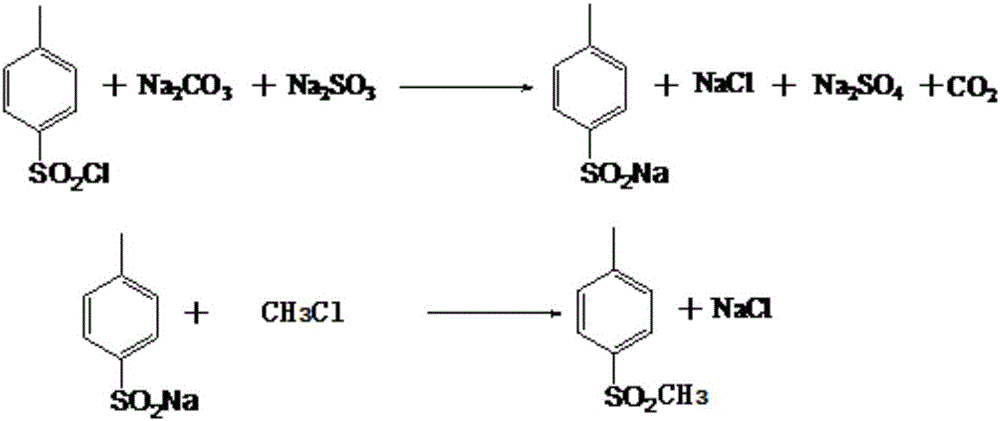

[0037] a) Add water to the salt forming kettle in proportion, start stirring and heat up to 32°C-35°C, add sodium carbonate, anhydrous sodium sulfite, and p-toluenesulfonyl chloride in proportion, and let the materials react naturally after closing the manhole, and the time is 40 -60 minutes;

[0038] b) After the salt-forming reaction is finished, feed steam to raise the temperature to 78°C-82°C, turn off the steam and keep it warm for 50-70 minutes to prepare a sodium p-toluenesulfinate solution;

[0039] c) After the heat preservation is over, open the manhole, add 150-250 mesh activated carbon in proportion under stirring, heat filtration for 10-30 minutes, reflux, and after the solution is completely clarified, directly replace it into the methylation reaction kettle;

[0040] d) After the filtration is finished, feed ...

Embodiment 2

[0050] In the step a), add 2000kg of water to the salt-forming kettle in proportion, start stirring and heat up to 32°C, add 290kg of sodium carbonate, 330kg of anhydrous sodium sulfite, and 450kg of p-toluenesulfonyl chloride at one time, and let the The material reacts naturally, and the time is 40 minutes;

[0051] In step b), after the salt-forming reaction is completed, the temperature in the kettle rises to between 65°C and 75°C, and steam is introduced to raise the temperature to 78°C, and the steam is turned off to keep the temperature for 50 minutes to prepare a sodium p-toluenesulfinate solution;

[0052] In step c), after the heat preservation is finished, open the manhole, add 150 mesh activated carbon in proportion under stirring, and stir for 10 minutes to carry out hot filtration;

[0053] In step d), after the filtration is completed, feed steam to raise the temperature, close the steam at 82°C, open the methyl chloride pipeline valve to carry out the methylati...

Embodiment 3

[0056] Embodiment 3: In the described step a), add 2200kg of water in the salt forming kettle in proportion, start stirring and heat up to 35°C, throw in 330kg of sodium carbonate, 390kg of anhydrous sodium sulfite, and 550kg of p-toluenesulfonyl chloride at one time, and close the After the manhole, let the material react naturally for 60 minutes;

[0057] In step b), after the salt-forming reaction is completed, the temperature in the kettle rises to between 65°C and 75°C, the temperature is raised to 82°C by feeding steam, and the steam is turned off for 70 minutes to prepare a sodium p-toluenesulfinate solution;

[0058] In step c), after the heat preservation is finished, open the manhole, add 250 mesh activated carbon in proportion under stirring, and stir for 30 minutes to carry out hot filtration;

[0059] In step d), after the filtration is completed, feed steam to raise the temperature, close the steam at 85°C, open the methyl chloride pipeline valve to carry out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com