Preparation method of ATO/SiO2/waterborne polyacrylate composite microsphere

A polyacrylate and acrylate technology, which is applied in the field of preparation of ATO/SiO2/water-based polyacrylate composite microspheres, can solve the problems of long production process, unfavorable industrialization of transparent thermal insulation coatings, complicated and complicated processes, etc. , to achieve the effect of short process, huge energy saving significance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

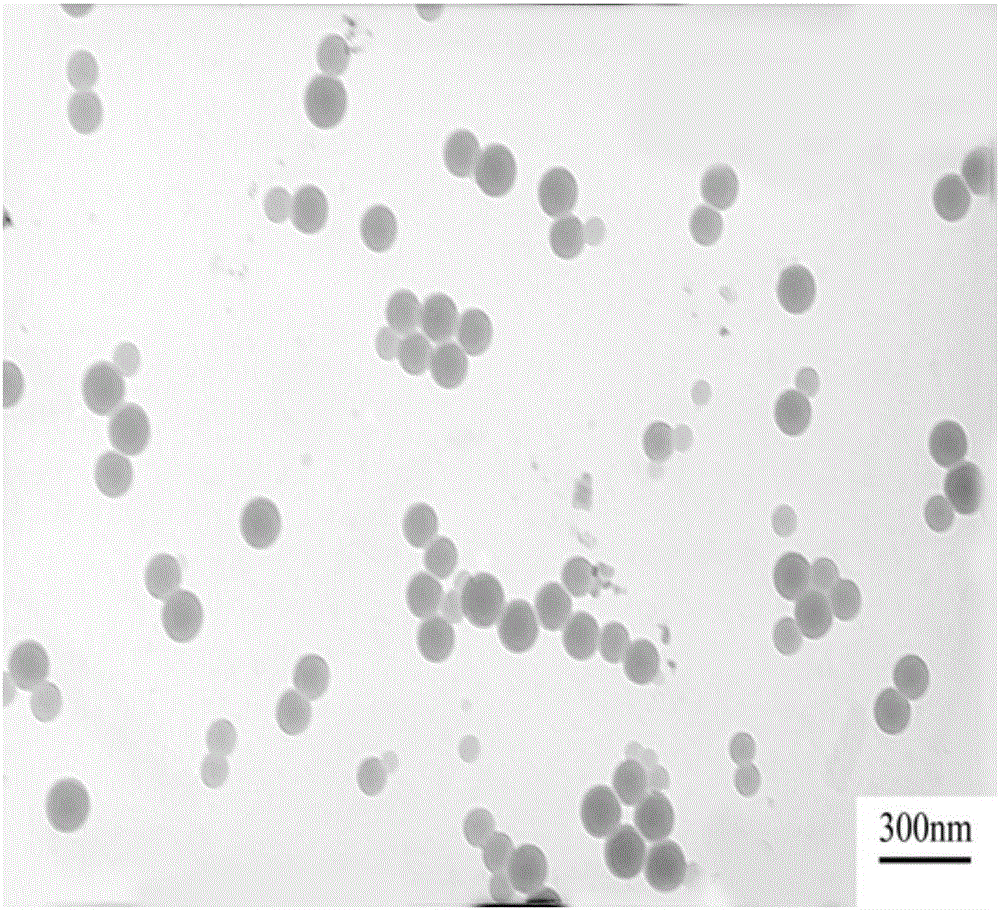

Embodiment 1

[0034] (1) Nano ATO powder is dispersed in ethanol aqueous solution, ethanol: water volume ratio is 1:1, adjusts the pH of solution to 8-10 with the ammonia solution of mass concentration 5-10%, controls the ATO mass concentration in the solution to be 5%, and then under the action of a high-speed disperser at a shear rate of 5000 rpm, disperse for 10 minutes to obtain an ATO dispersion.

[0035] (2) The ATO dispersion prepared in step (1) is used to modify the surface of ATO with a silane coupling agent. The amount of silane coupling agent is 5% of the mass of ATO, and the ATO dispersion and silane coupling agent are mixed and refluxed at 60°C for 240 minutes to prepare ATO / SiO with unsaturated double bonds 2 Composite suspension, wherein the silane coupling agent is: 3-aminopropyltriethoxysilane, N-2-aminoethyl-3-aminopropylmethyldimethoxysilane, vinyltrimethoxysilane .

[0036] (3) ATO / SiO prepared in step (2) 2 Composite suspension, distill ethanol in the solution at 70...

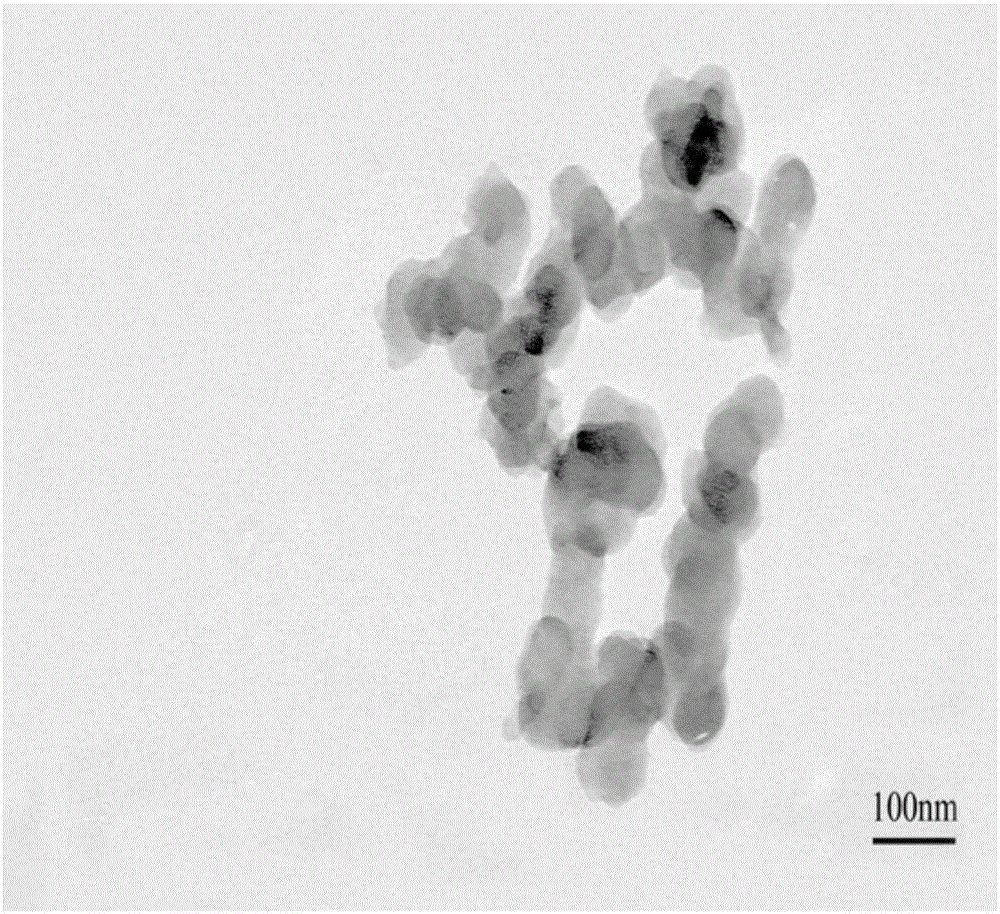

Embodiment 2

[0041] (1) Nano ATO powder is dispersed in ethanol aqueous solution, ethanol: water volume ratio is 9:1, adjusts the pH of solution to 8-10 with the ammonia solution of mass concentration 5-10%, controls the ATO mass concentration in the solution to be 15%, and then disperse for 20 minutes at a shear rate of 8000 rpm under the action of a high-speed disperser to obtain an ATO dispersion.

[0042] (2) The ATO dispersion prepared in step (1) is used to modify the surface of ATO with a silane coupling agent. The amount of silane coupling agent is 10% of the mass of ATO, ATO dispersion and silane coupling agent are mixed and refluxed at 90°C for 60 minutes to prepare ATO / SiO with unsaturated double bonds 2 Composite suspension, wherein the silane coupling agent is: vinyl tris (2-methoxyethoxy) silane, vinyl triethoxy silane (VTES).

[0043] (3) ATO / SiO prepared in step (2) 2 Composite suspension, distill ethanol in the solution at 80°C, add acrylate polymer monomer, add polymeri...

Embodiment 3

[0048] (1) Nano ATO powder is dispersed in ethanol aqueous solution, ethanol: water volume ratio is 5: 1, adjusts the pH of solution to 8-10 with the ammonia solution of mass concentration 5-10%, controls the ATO mass concentration in the solution to be 10%, and then under the action of a high-speed disperser at a shear rate of 6000 rpm, disperse for 5 minutes to obtain an ATO dispersion.

[0049] (2) The ATO dispersion prepared in step (1) is used to modify the surface of ATO with a silane coupling agent. The amount of silane coupling agent is 8% of the mass of ATO, and the ATO dispersion and silane coupling agent are mixed and refluxed at 90°C for 140 minutes to prepare ATO / SiO with unsaturated double bonds 2 Complex suspension, wherein the silane coupling agent is: N-2-aminoethyl-3-aminopropyltrimethoxysilane, 3-mercaptopropyltriethoxysilane, γ-methacryloyloxypropyl Trimethoxysilane (MPS).

[0050] (3) ATO / SiO prepared in step (2) 2 Composite suspension, distill ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com