Flexible anti-corrosion belt as well as preparation method and application thereof

An anti-corrosion and flexible technology, applied in the field of flexible anti-corrosion tape and its preparation, can solve the problems of cumbersome construction procedures and achieve the effects of convenient coating and removal operations, simple preparation conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

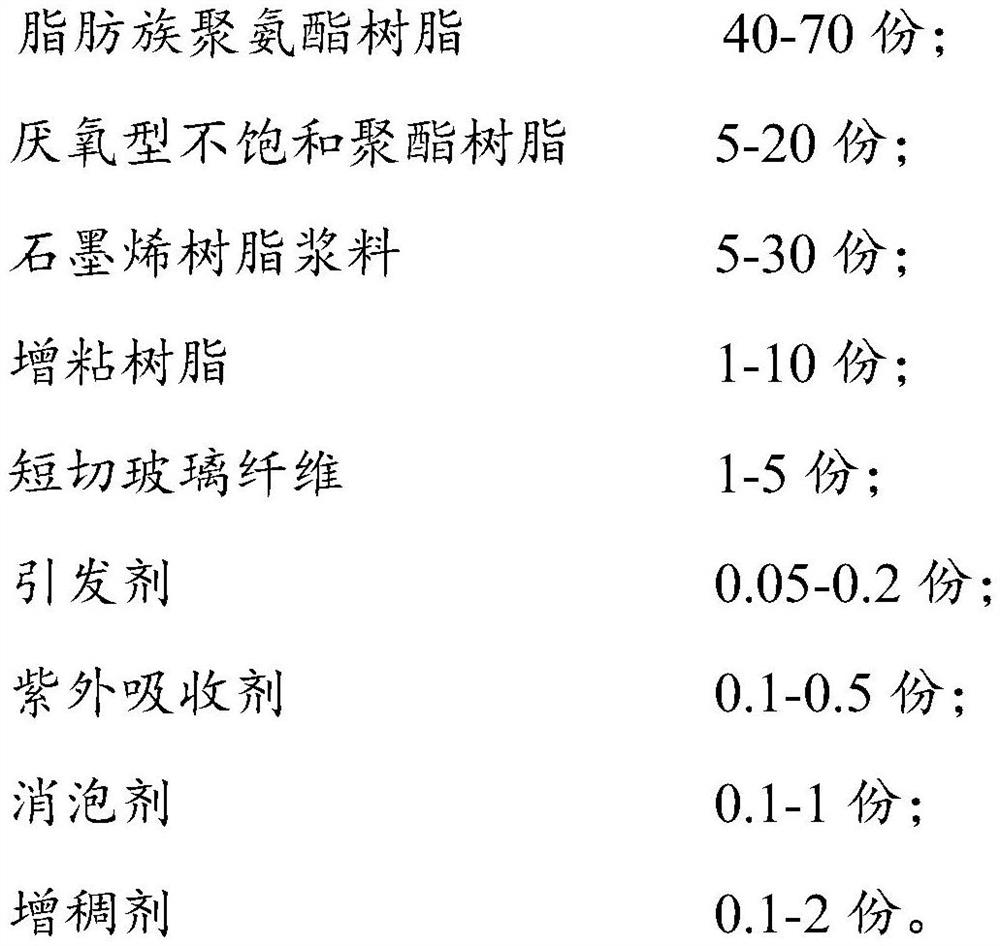

Method used

Image

Examples

Embodiment 1

[0043] S1, 5g of graphene resin slurry, 76.6g of liquid polyurethane resin with a solid content of 40%, 10g of 182# unsaturated polyester resin, 5g of liquid coumarone tackifying resin and 0.5g of BYK-051N defoamer through a shearing disperser at a speed of 1000rpm Disperse to obtain the resin mixture;

[0044] S2. Add 0.1g of methyl ethyl ketone peroxide initiator, 0.3g of UV-531 ultraviolet absorber and 2g of chopped glass fiber to the resin mixture prepared in S1 and disperse for 30min with a shear disperser at 300rpm, add 0.5g of gas phase II Silicon oxide thickener adjusts viscosity to make viscous coating solution;

[0045] S3. Coating the coating solution prepared in S2 on a 100 μm PET release film with a coating machine to form a film with a coating film thickness of 200 μm, transferred to a drying system and cured at 60° C. for 15 minutes to obtain an anti-corrosion tape.

[0046] After testing, the elongation at break of the anti-corrosion tape is 196%, the tensile ...

Embodiment 2

[0048] S1, disperse 10g graphene resin slurry, 71.6g aliphatic polyurethane resin, 10g182# unsaturated polyester resin, 5g liquid coumarone tackifying resin and 0.5g BYK-051N defoamer through a shear disperser at a speed of 1000rpm. resin mixture;

[0049] S2. Add 0.1g of methyl ethyl ketone peroxide initiator, 0.3g of UV-531 ultraviolet absorber and 2g of chopped glass fiber to the resin mixture prepared in S1 and disperse for 30min with a shear disperser at 300rpm, add 0.5g of gas phase II Silicon oxide thickener adjusts viscosity to make viscous coating solution;

[0050] S3. Coating the coating solution prepared in S2 on a 100 μm PET release film with a coating machine to form a film with a coating film thickness of 200 μm, transferred to a drying system and cured at 60° C. for 15 minutes to obtain an anti-corrosion tape.

[0051] After testing, the elongation at break of the anti-corrosion tape is 185%, the tensile strength is 14.1N / cm, the peel strength is 10.3N / cm, and...

Embodiment 3

[0053] S1, 20g graphene resin slurry, 61.6g aliphatic polyurethane resin, 10g182# unsaturated polyester resin, 5g liquid coumarone tackifying resin and 0.5g BYK-051N defoamer were prepared by dispersing under a shear disperser at a speed of 1000rpm resin mixture;

[0054] S2. Add 0.1g of methyl ethyl ketone peroxide initiator, 0.3g of UV-531 ultraviolet absorber and 2g of chopped glass fiber to the resin mixture prepared in S1 and disperse for 30min with a shear disperser at 300rpm, add 0.5g of gas phase II Silicon oxide thickener adjusts viscosity to make viscous coating solution;

[0055] S3. Coating the coating solution prepared in S2 on a 100 μm PET release film with a coating machine to form a film with a coating film thickness of 200 μm, transferred to a drying system and cured at 60° C. for 15 minutes to obtain an anti-corrosion tape.

[0056] After testing, the elongation at break of the anti-corrosion tape is 182%, the tensile strength is 13.4N / cm, the peel strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com