Industrial thermal insulation coating

A thermal insulation, industrial technology, used in asphalt coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve the problem that thermal insulation coatings do not have waterproof performance, affect the use time and effect of coatings, and waterproof emulsions do not have Thermal insulation performance and other issues, to achieve the effect of improving smearability, ductility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

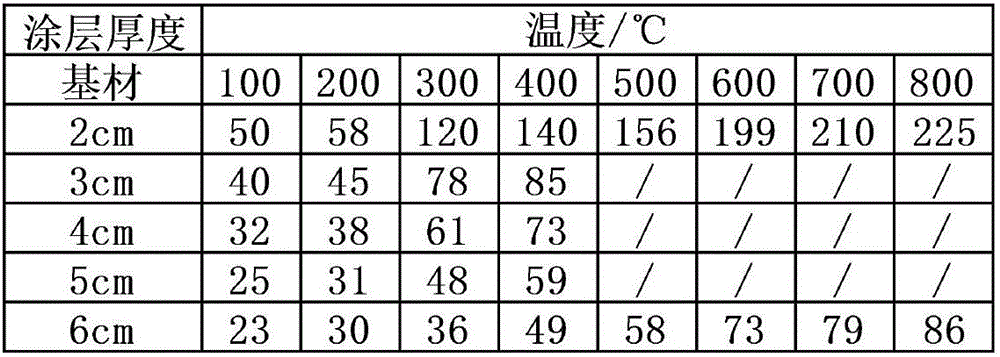

Image

Examples

Embodiment 1

[0026] The industrial thermal insulation coating of this embodiment comprises surface coating and primer;

[0027] The surface coating contains in parts by mass: 10-15 parts of waterproof emulsion, 2-3 parts of heavy calcium, 5-10 parts of titanium dioxide, 5-10 parts of vacuum ceramic microbeads, and 1-5 parts of microsilica.

[0028] The primer coating contains in parts by mass: 5-10 parts of high temperature resistant fiber, 75-85 parts of water, 0.5-1.5 parts of surfactant, 0.5-1.5 parts of thickener, 3-8 parts of binder, 12- 18 parts, microsilica powder 4-8 parts, fumed silica 5-8 parts, vacuum ceramic microbeads 30-40 parts, vitrified microbeads 6-10 parts, floating beads 5-8 parts. The particle size of the vacuum ceramic beads is 1-120um, the particle size of the vitrified beads is 300-600um, the particle size of the floating beads is 30-100um, the particle size of the fumed silica is 7-40nm, and the titanium dioxide The particle size is 10-400nm.

[0029] The primer ...

Embodiment 2

[0035] The difference between this embodiment and the above-mentioned embodiments is that the industrial thermal insulation coating of this embodiment includes a surface coating and a primer;

[0036] The surface coating contains in parts by mass: 10 parts of polyacrylic acid waterproof emulsion, 2 parts of heavy calcium, 5 parts of titanium dioxide, 5 parts of vacuum ceramic microbeads, and 1 part of microsilica.

[0037] The primer contains by mass parts: 5 parts of carbon fiber, 75 parts of water, 0.4 part of disodium lauryl polyoxyethylene ether sulfosuccinic acid monoester, 0.1 part of sodium diisooctyl sulfonate, methyl cellulose 0.5 parts of plain thickener, 0.5 parts of polyacrylamide, 2 parts of hydroxypropyl methylcellulose, 0.5 parts of starch ether, 12 parts of titanium dioxide, 4 parts of microsilica fume, 5 parts of fumed silica, vacuum ceramic microspheres 30 parts, 6 parts of vitrified microbeads, 5 parts of floating beads.

Embodiment 3

[0039] The difference between this embodiment and the above-mentioned embodiments is that the industrial thermal insulation coating of this embodiment includes a surface coating and a primer;

[0040] The surface coating contains in parts by mass: 15 parts of polyurethane waterproof emulsion, 3 parts of heavy calcium, 10 parts of titanium dioxide, 10 parts of vacuum ceramic microbeads, and 5 parts of microsilica.

[0041] The primer contains in parts by mass: 10 parts of aluminum silicate fiber, 85 parts of water, 1 part of disodium lauryl polyoxyethylene ether sulfosuccinic acid monoester, 0.5 part of sodium diisooctyl sulfonate, 1.5 parts of hydroxyethyl cellulose thickener, 1 part of polyacrylamide, 6 parts of hydroxypropyl methylcellulose, 1 part of starch ether, 18 parts of titanium dioxide, 8 parts of microsilica fume, 8 parts of fumed silica, 40 parts of vacuum ceramic microbeads, 10 parts of vitrified microbeads, and 8 parts of floating beads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com