Cr<3+>-doped zinc gallate near-infrared long-afterglow luminescent nanoparticles and preparation method

A nanoparticle, zinc gallate technology, applied in luminescent materials, luminescent coatings, chemical instruments and methods, etc., can solve the problems affecting the application of near-infrared long afterglow luminescent nanomaterials, serious agglomeration of long afterglow nanoparticles, and complicated preparation steps. , to achieve the effect of easy large-scale promotion and use, low cost of raw materials, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

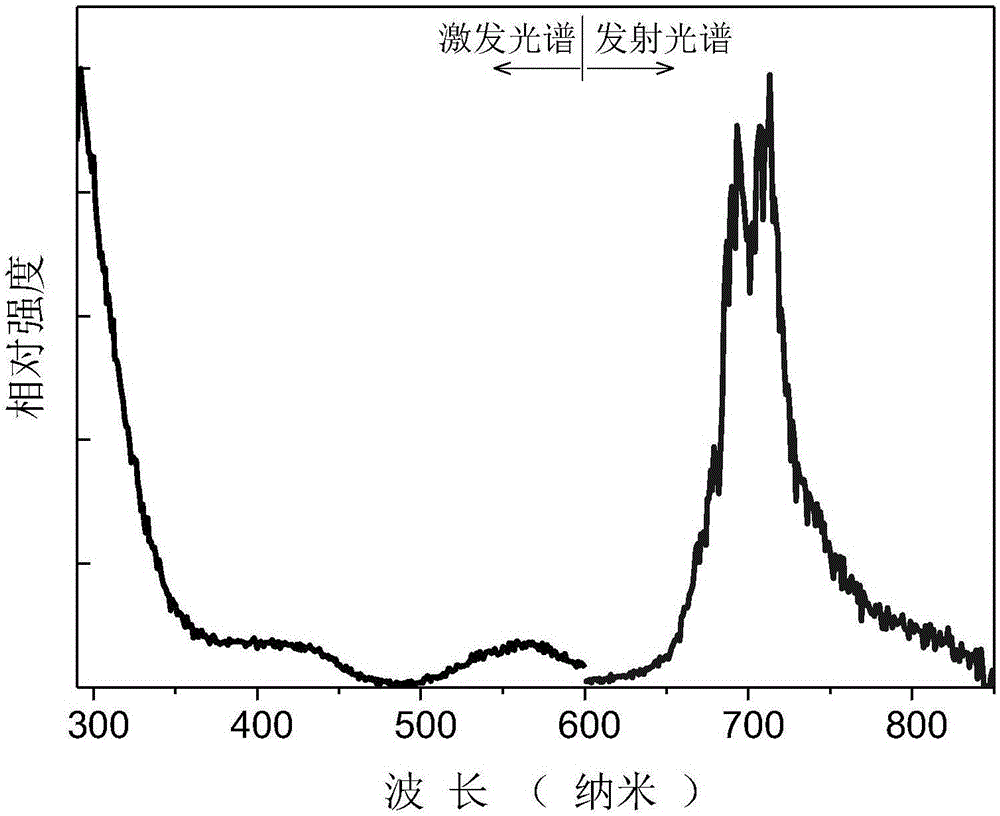

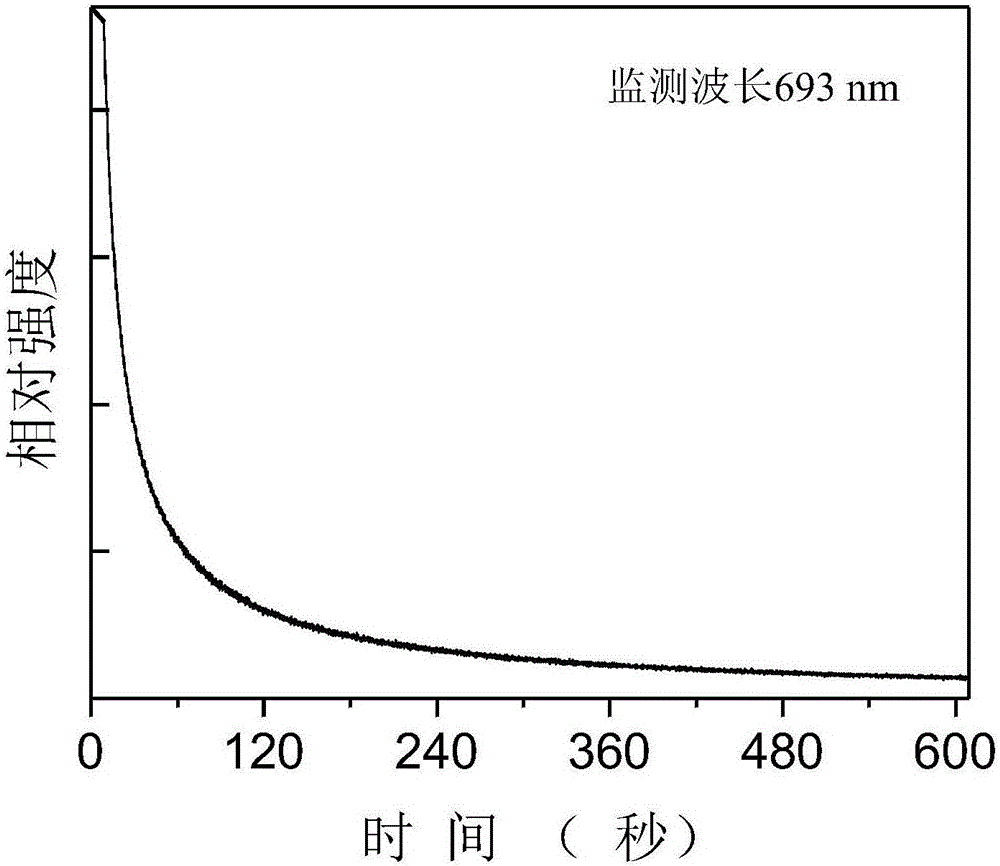

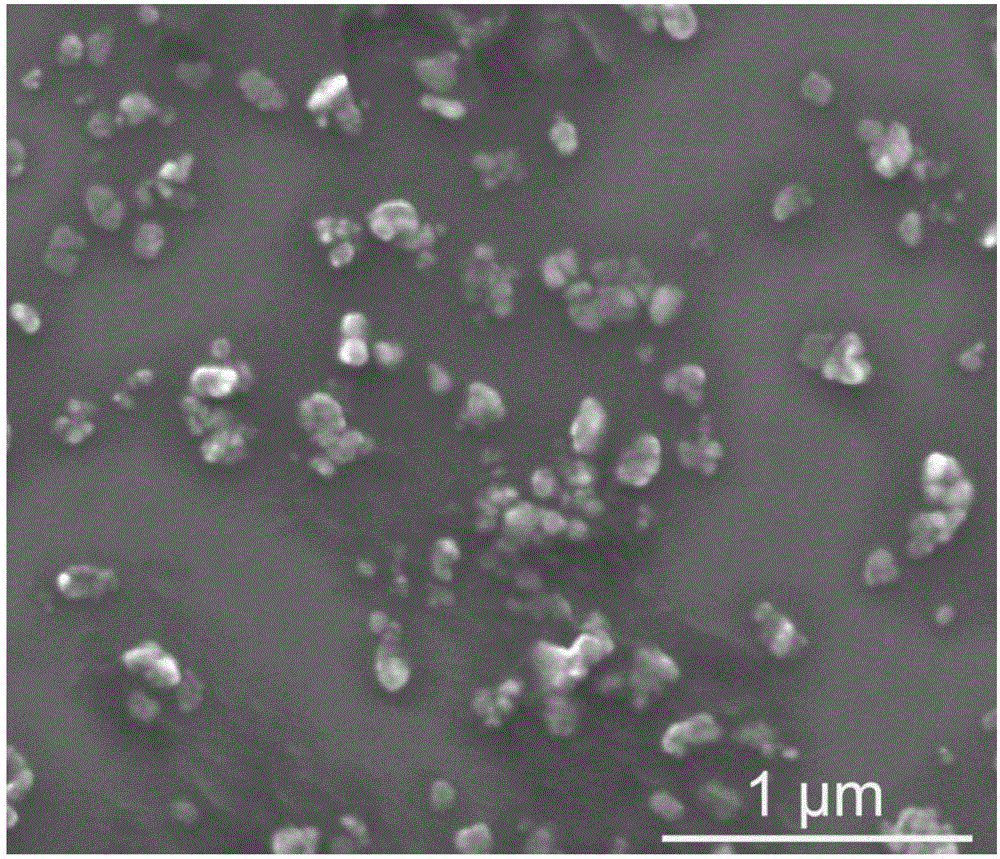

Embodiment 1

[0040] Add 10ml 0.1mol / L Zn(NO 3 ) 2 Solution, 19.95ml 0.1mol / L Ga(NO 3 ) 3 solution, 0.1ml 0.05mol / L Cr(NO 3 ) 3 solution, after stirring, the reactant nitrate mixture was obtained. Then add 0.2459g glycine and 0.1180g carbohydrazide to the above mixed solution as organic fuel. Evaporate slowly in a water bath at 80°C until the mixed solution becomes a uniform and transparent sol. Put the above sol into a muffle furnace with a furnace temperature of 600°C to ignite, and the combustion reaction is completed rapidly within tens of seconds, and a white fluffy product is obtained. Transfer the above white product into an agate mortar, add 5mmol / L sodium hydroxide solution and grind it thoroughly for 1h. Add the ground mixed slurry into distilled water and ultrasonically treat it for 1 hour. The mass ratio of distilled water to white product is 1000:1. After standing still for 72 hours, take the supernatant and centrifuge at 10000 rpm for 10 minutes at a high speed to obtai...

Embodiment 2

[0046] Add 10ml Zn(NO 3 ) 2 solution, 19.98ml Ga(NO 3 ) 3 solution, 0.04ml Cr(NO 3 ) 3 solution, after stirring, the reactant nitrate mixture was obtained. Then add 0.2459g glycine and 0.1180g carbohydrazide to the above mixed solution as organic fuel. Evaporate slowly in a water bath at 80°C until the mixed solution becomes a uniform and transparent sol. Put the above sol into a muffle furnace with a furnace temperature of 500°C to ignite, and the combustion reaction is completed rapidly within tens of seconds, and a white fluffy product is obtained. Transfer the above white product into an agate mortar, add 5mmol / L sodium hydroxide solution and grind it thoroughly for 1h. Add the ground mixed slurry into distilled water and ultrasonically treat it for 1 hour. The mass ratio of distilled water to white product is 1000:1. After standing for 72 hours, take the supernatant and centrifuge at 10,000 rpm for 10 minutes to obtain near-infrared particles with an average partic...

Embodiment 3

[0048] Add 10ml Zn(NO 3 ) 2 solution, 19.9ml Ga(NO 3 ) 3 solution, 0.2ml Cr(NO 3 ) 3 solution, after stirring, the reactant nitrate mixture was obtained. Then add 0.2459g glycine and 0.1180g carbohydrazide to the above mixed solution as organic fuel. Evaporate slowly in a water bath at 80°C until the mixed solution becomes a uniform and transparent sol. Put the above sol into a muffle furnace with a furnace temperature of 700°C to ignite, and the combustion reaction is completed rapidly within tens of seconds, and a white fluffy product is obtained. Transfer the above white product into an agate mortar, add 5mmol / L sodium hydroxide solution and grind it thoroughly for 1h. Add the ground mixed slurry into distilled water and ultrasonically treat it for 1 hour. The mass ratio of distilled water to white product is 1000:1. After standing for 72 hours, take the supernatant and centrifuge at 10,000 rpm for 10 minutes to obtain near-infrared particles with an average particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com