Steel and iron surface passivating treatment liquid

A passivation treatment, steel surface technology, applied in the direction of metal material coating process, etc., can solve the problems of affecting metal corrosion resistance, affecting passivation effect, and non-smooth protective film, achieving low cost, excellent corrosion resistance, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

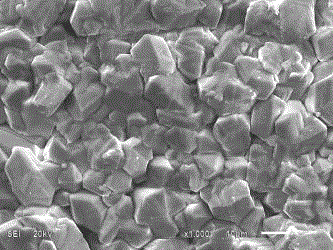

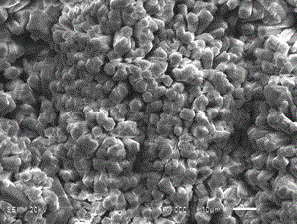

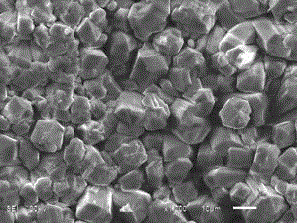

Image

Examples

Embodiment 1

[0034] 1. A steel surface passivation treatment solution containing the following components: 6.3% hydrofluoric acid, 1.8% potassium fluorosilicate, 1.6% cerium nitrate, 0.5% peracetic acid, H 2 o 2 1.0%, sodium benzoate 2.3%, lauryl dimethyl ammonium chloride 0.01%, hexamethylenetetramine 0.002%, and the rest is water, and the pH of the treatment solution is adjusted to be 4 with hydrochloric acid.

[0035] The preparation method of the steel surface passivation treatment solution is as follows: weighing the components in the formula by weight, mixing, stirring evenly, and adjusting the treatment solution to pH=4 with hydrochloric acid.

Embodiment 2

[0037] A steel surface passivation treatment solution, containing the following components: 1% hydrofluoric acid, 0.1% sodium fluorosilicate, 0.1% cerous nitrate, 0.1% sodium peroxide, 5% sodium benzoate, tetradecyl dimethyl Ammonium chloride 0.5%, hexamethylenetetramine 0.005%, and the rest is water, and the pH of the treatment solution is adjusted to 2 with hydrochloric acid.

[0038] Its preparation method is the same as in Example 1, and the pH of the treatment solution is adjusted to 2 with hydrochloric acid.

Embodiment 3

[0040] A steel surface passivation treatment solution, containing the following components: 15% hydrofluoric acid, 5% magnesium fluorosilicate, 5% cerium trichloride, 5% ammonium persulfate, 0.1% sodium benzoate, dodecyl dimethyl Ammonium chloride 0.001%, hexamethylenetetramine 0.001%, the rest is water, and the pH of the treatment solution is adjusted to 5 with hydrochloric acid.

[0041] Its preparation method is the same as in Example 1, and the pH of the treatment solution is adjusted to 5 with hydrochloric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com