Preparation method of super capacitor based on single-wall carbon nanotube/tungsten oxide nanowire composite film electrodes

A technology of single-walled carbon nanotubes and tungsten oxide nanowires, which is applied in the field of preparation of supercapacitor film electrodes, can solve the problems of complex preparation process of composite electrode materials, unfavorable micro-nano structure for aluminum ion embedding, and poor bending performance of supercapacitors. Achieve the effects of overcoming poor cycle stability, low cost, and improving specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

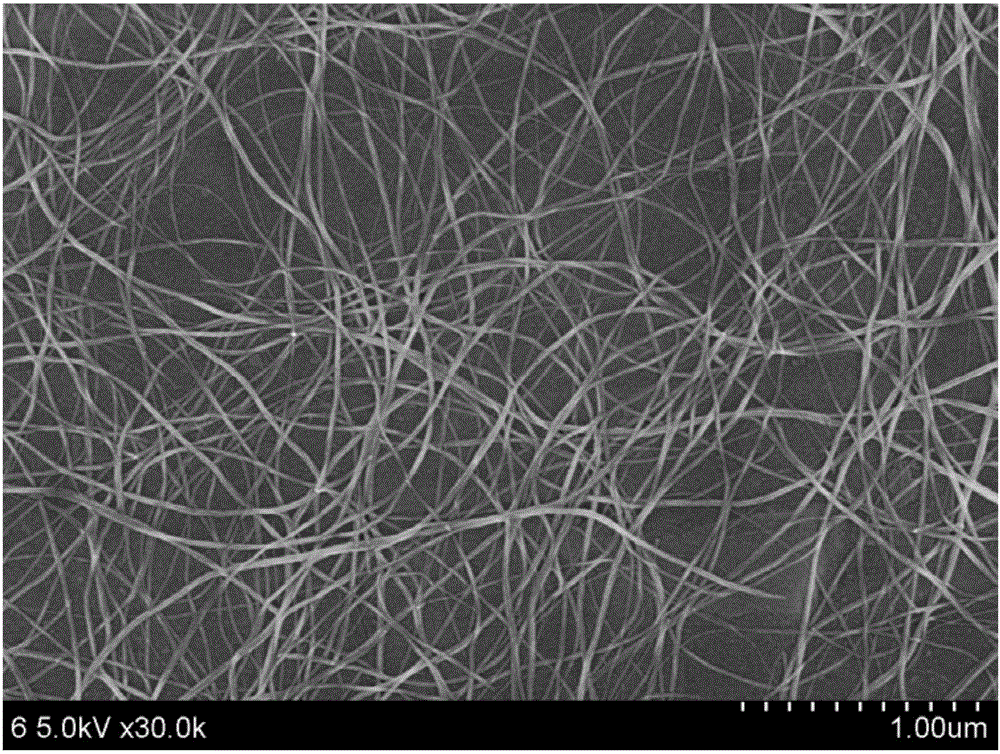

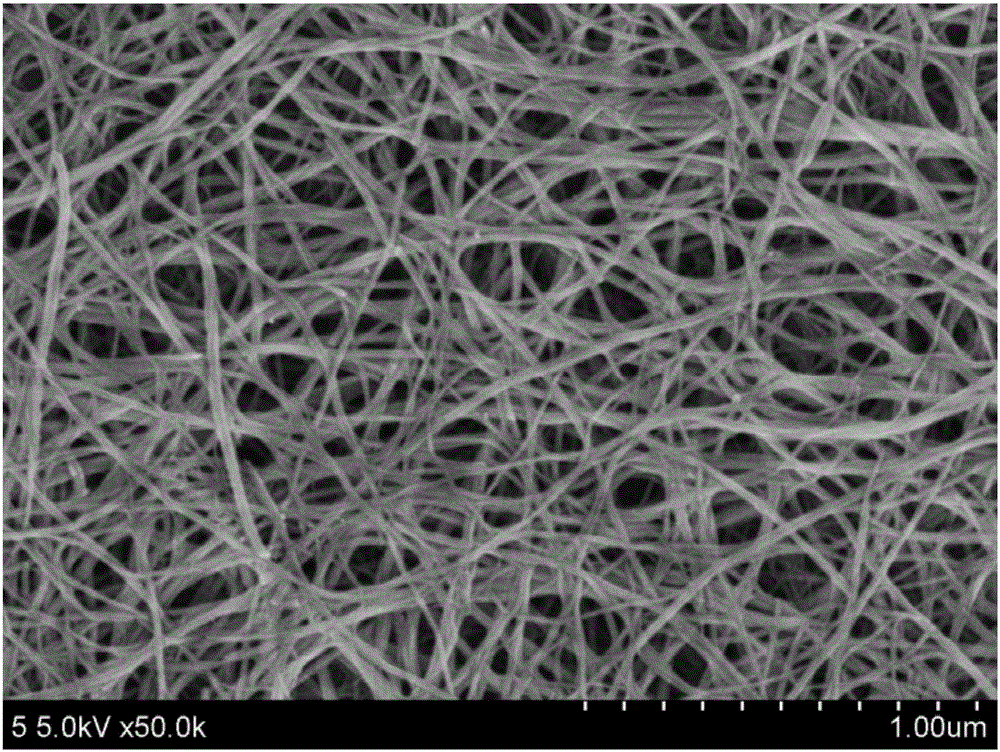

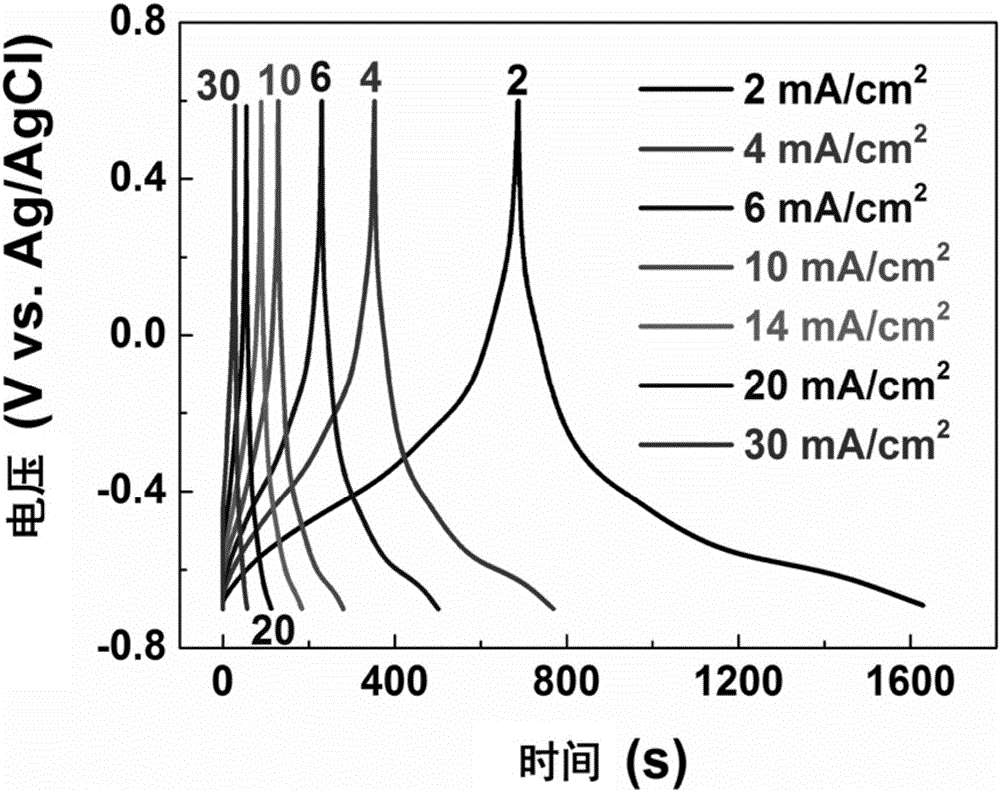

Embodiment 1

[0031] In an air environment with a humidity of 50%, put polyvinylpyrrolidone and tungsten hexachloride into absolute ethanol solution and stir respectively to obtain a precursor solution containing 7 μg / ml polyvinylpyrrolidone and 0.75 mg / ml tungsten hexachloride, The solution was placed in a hydrothermal kettle, kept at 180°C for 18 hours, cooled to room temperature naturally, centrifuged and washed, then added to deionized water to obtain 3 mg / ml W 18 o 49 nanowire dispersion. The suspension containing 15 mg of single-walled carbon nanotubes was mixed with 15 ml of the above W 18 o 49 The nanowire dispersion is mixed, suction filtered, washed and dried to obtain single-walled carbon nanotubes / W 18 o 49 Nanowire flexible composite thin film electrodes. The obtained composite film is used as the cathode, the single-walled carbon nanotube / polyaniline film is used as the anode, and 1mol / L aluminum chloride aqueous solution is used as the electrolyte, and an aluminum ion su...

Embodiment 2

[0033] In an air environment with a humidity of 20%, put polyvinylpyrrolidone and tungsten hexachloride into absolute ethanol solution and stir respectively to obtain a precursor solution containing 7 μg / ml polyvinylpyrrolidone and 0.2 mg / ml tungsten hexachloride, The solution was placed in a hydrothermal kettle, kept at 160°C for 18 hours, cooled to room temperature naturally, centrifuged and washed, then added to deionized water to obtain 3 mg / ml W 18 o 49nanowire dispersion. The suspension containing 15 mg of single-walled carbon nanotubes was mixed with 15 ml of the above W 18 o 49 The nanowire dispersion is mixed, suction filtered, washed and dried to obtain single-walled carbon nanotubes / W 18 o 49 Nanowire flexible composite thin film electrodes. The obtained composite film was used as the cathode, the single-walled carbon nanotube / polyaniline film was used as the anode, and the 1mol / L aluminum nitrate aqueous solution was used as the electrolyte, and an aluminum io...

Embodiment 3

[0035] In an air environment with a humidity of 20%, put polyvinylpyrrolidone and tungsten hexachloride into absolute ethanol solution and stir respectively to obtain a precursor solution containing 5 μg / ml polyvinylpyrrolidone and 1.2 mg / ml tungsten hexachloride, The solution was placed in a hydrothermal kettle, kept at 180°C for 18 hours, cooled to room temperature naturally, centrifuged and washed, then added to deionized water to obtain 5mg / ml W 18 o 49 nanowire dispersion. The suspension containing 10 mg of single-walled carbon nanotubes was mixed with 10 ml of the above W 18 o 49 The nanowire dispersion is mixed, suction filtered, washed and dried to obtain single-walled carbon nanotubes / W 18 o 49 Nanowire flexible composite thin film electrodes. The obtained composite film is used as the cathode, the single-walled carbon nanotube / polyaniline film is used as the anode, and the 0.5 mol / L aluminum nitrate aqueous solution is used as the electrolyte, and an aluminum io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com