Graphene loaded Co-N-C super-molecule hybrid aerogel composite material, preparation method thereof and application

A composite material, graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of unstable aerogel structure, limited development and application, low strength, etc., achieve significant catalytic effect, improve electrical performance, The effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

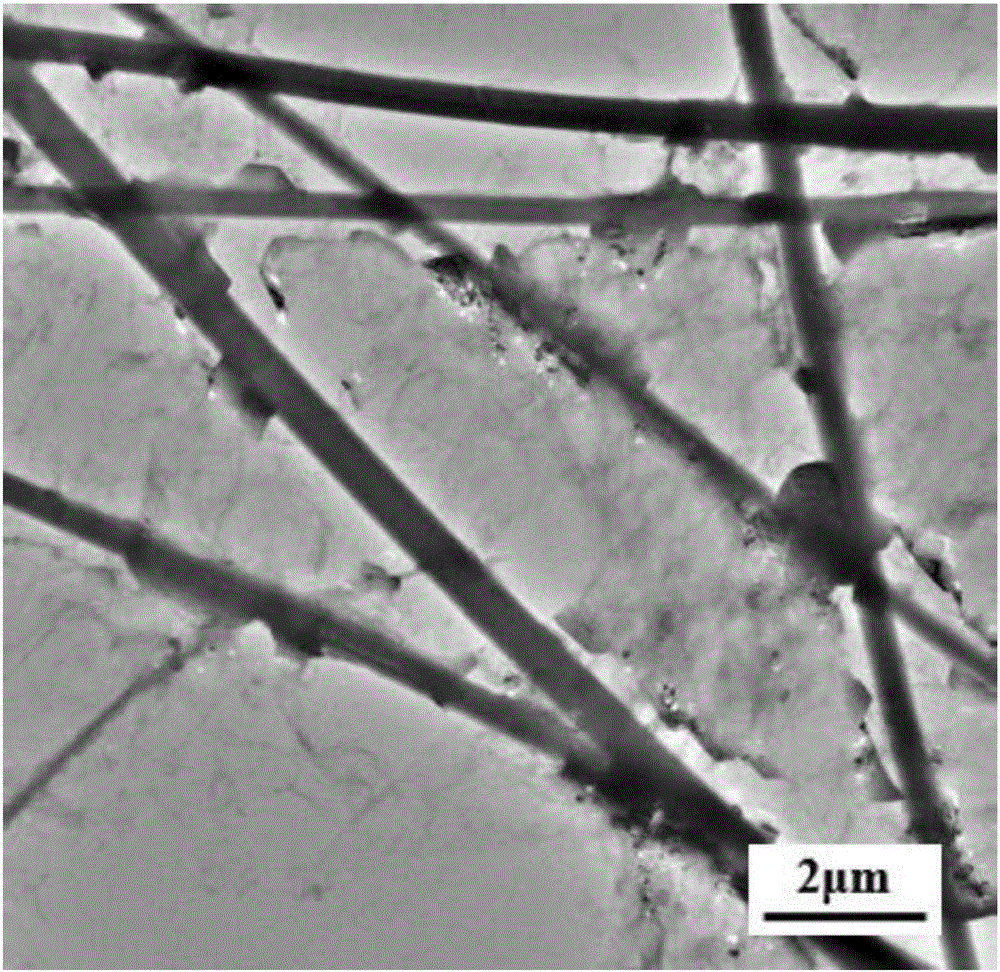

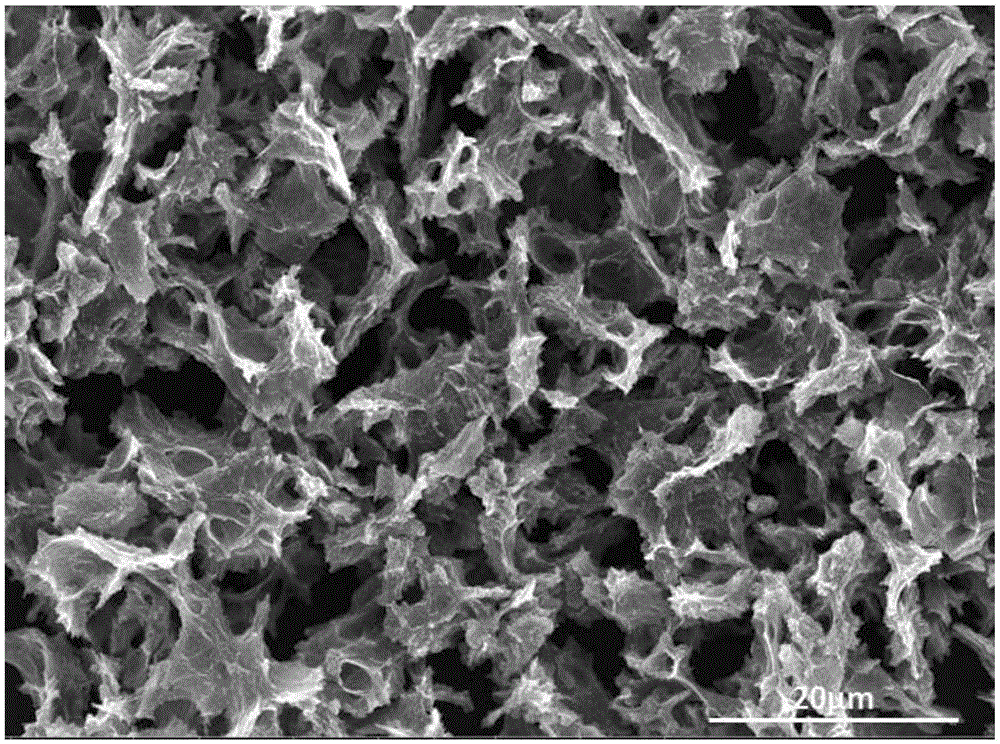

[0042] A graphene-loaded Co-N-C supramolecular hybrid airgel composite material of the present invention, the composite material is a black sponge-like three-dimensional porous network structure, the composite material uses graphene as a substrate, and the graphene substrate and pyridine- Tryptophan gelling factor and cobalt ions assembled to form Co-N-C active catalytic center through non-covalent interaction. The Co-N-C active catalytic center is formed by doping the defects of graphene after coordinating the pyridine-tryptophan gel factor with cobalt ions. The composite material has a significant catalytic effect on the oxygen reduction reaction, and the current density can reach 4mA / cm 2 , the oxygen reduction onset potential is about -0.07V, the peak potential is about -0.175V, the catalytic effect is comparable to commercial platinum carbon, and its stability is very good, the current signal is almost unchanged after cyclic voltammetry scanning for 10,000 cycles, and it ...

Embodiment 2

[0059] A graphene-loaded Co-N-C supramolecular hybrid airgel composite material of the present invention, the composite material is a black sponge-like three-dimensional porous network structure, the composite material uses graphene as a substrate, and the graphene substrate and pyridine- Tryptophan gelling factor and cobalt ions assembled to form Co-N-C active catalytic center through non-covalent interaction. The Co-N-C active catalytic center is formed by doping the defects of graphene after coordinating the pyridine-tryptophan gel factor with cobalt ions.

[0060] The graphene-loaded Co-N-C supramolecular hybrid airgel composite material is composed of pyridine-tryptophan gel factor, cobalt acetate solution and graphene oxide flakes with a thickness of about 1 nm, after in-situ hydrothermal treatment, vacuum freeze-drying, Obtained after high temperature carbonization treatment. The schematic diagram of the preparation method is shown in figure 1 Shown, its specific prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com