Positive electrode for secondary cell, method for manufacturing positive electrode secondary cell, and secondary cell

A secondary battery and manufacturing method technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte storage battery electrodes, etc., can solve the problems of softness and adhesion of the positive electrode composite material layer, and achieve excellent output characteristics, softness Excellent effect of sex and adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] -Method for producing polymer (B)-

[0117] The method for producing the polymer (B) is not particularly limited, and it can be produced, for example, by polymerizing a monomer composition containing the above-mentioned monomers to obtain a polymer, and optionally hydrogenating the obtained polymer.

[0118] Here, in the present invention, the content ratio of each monomer in the monomer composition can be determined based on the content ratio of each monomer unit and structural unit (repeating unit) in the polymer (B).

[0119] The polymerization method is not particularly limited, and any of solution polymerization, suspension polymerization, bulk polymerization, emulsion polymerization, and the like can be used. In addition, as the polymerization reaction, any of ionic polymerization, radical polymerization, living radical polymerization, and the like can be used. Moreover, at the time of polymerization, a known emulsifier and a polymerization initiator can be used ...

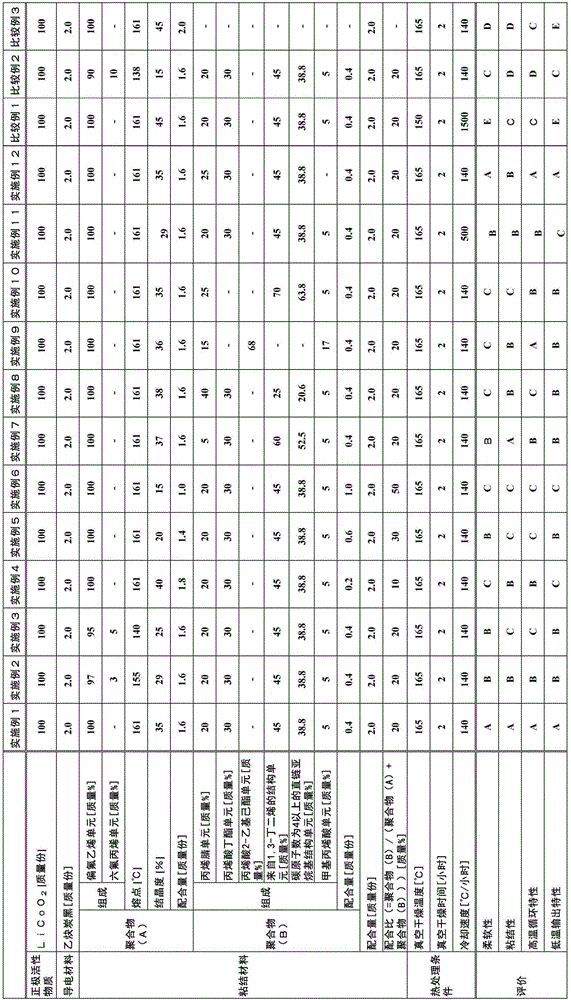

Embodiment 1

[0200]

[0201] Polyvinylidene fluoride (manufactured by Kureha Corporation, KF Polymer #7200, melting point: 161° C.) was prepared as the polymer (A).

[0202]

[0203] 240 parts of ion-exchanged water, 2.5 parts of sodium alkylbenzenesulfonate, 20 parts of acrylonitrile as a nitrile group-containing monomer, 30 parts of butyl acrylate as a (meth)acrylate monomer, 5 parts 45 parts of methacrylic acid as a monomer containing a hydrophilic group are charged into a high-pressure reactor with a stirrer in this order, and after the bottle is replaced with nitrogen, 45 parts of methacrylic acid as a conjugated diene monomer Add 0.25 parts of ammonium persulfate to the 1,3-butadiene, and make it polymerize at a reaction temperature of 40°C. Then, a polymer including a nitrile group-containing monomer unit, a (meth)acrylate monomer unit, a hydrophilic group-containing monomer unit, and a conjugated diene monomer unit is obtained. In addition, the polymerization conversion rate w...

Embodiment 2

[0220] A copolymer of vinylidene fluoride and hexafluoropropylene (manufactured by Arkema, Kynar flex 2850-00, content ratio of vinylidene fluoride unit: 97% by mass, melting point: 155° C.) was used as the polymer (A) instead of polyvinylidene fluoride. , except that, it carried out similarly to Example 1, the slurry composition for positive electrodes, the positive electrode for lithium ion secondary batteries, the negative electrode for lithium ion secondary batteries, and lithium ion secondary batteries were manufactured, and it evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com