Heat-rash-dispelling, itch-relieving and mosquito-repelling cotton fabric containing peach leaf extract and preparation method thereof

A kind of mosquito-cotton fabric, technology of extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

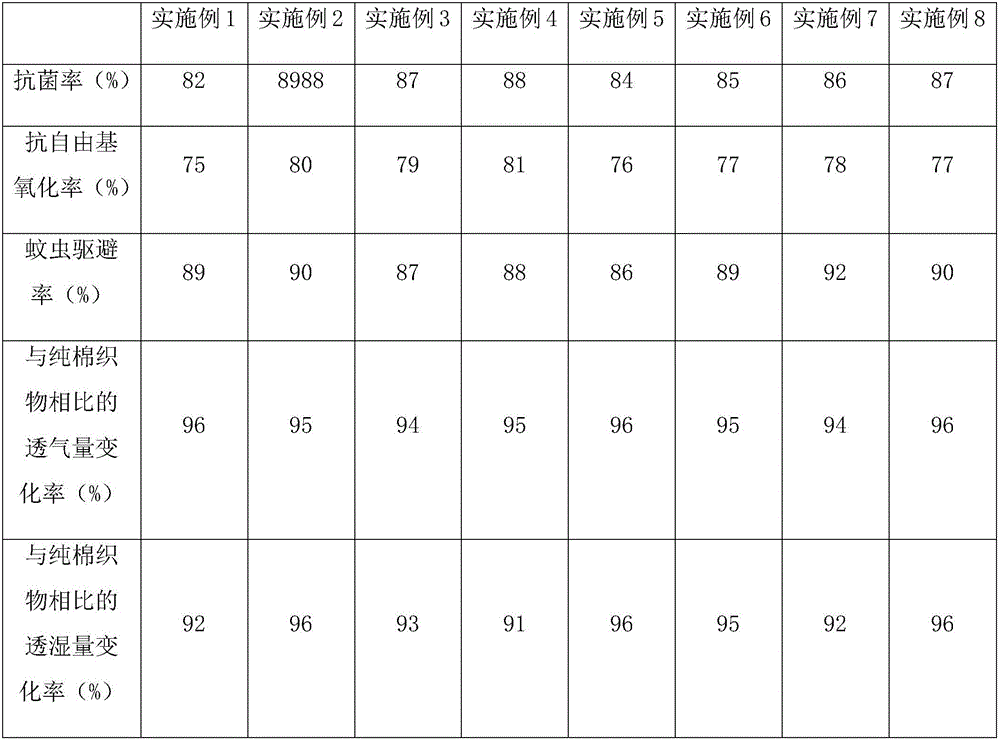

Examples

Embodiment 1

[0027] (1) Wash the fresh peach leaves, steam anti-virus, dry in the shade, crush, and sieve to form peach leaf powder with a particle size of 1-20 μm. Stand by, the peach leaf powder is immersed in the Stand still in ethanol aqueous solution with a volume ratio of 1:0.5 for 6 hours, heat and extract at 60°C for 2 hours, filter to obtain the primary extract of flavonoids and naringenin and the primary filter residue, and the primary filter residue with a solid-liquid ratio of 1g:40ml, Immerse in a methanol solution, heat and extract at 50°C for 3 hours, filter to obtain the secondary extract of quinic acid and the secondary filter residue, and immerse the secondary filter residue in a petroleum ether solution at a material-to-liquid ratio of 1g:40ml. Under ultrasonic extraction for 30 minutes, three times of lycopene extracts and three times of filter residues were obtained by filtration.

[0028] (2) The first extract, the second extract, and the third extract are mixed, conc...

Embodiment 2

[0031] (1) Wash the fresh peach leaves, steam anti-virus, dry in the shade, crush, and sieve to form peach leaf powder with a particle size of 1-20 μm. Stand by, the peach leaf powder is immersed in the Stand still in ethanol aqueous solution with a volume ratio of 1:0.8 for 10 hours, heat and extract at 60°C for 3 hours, filter to obtain the primary extract of flavonoids and naringenin and the primary filter residue, and the primary filter residue with a solid-liquid ratio of 1g:50ml, Immerse in a methanol solution, heat and extract at 50°C for 4h, filter to obtain the secondary extract of quinic acid and the secondary filter residue, and immerse the secondary filter residue in a petroleum ether solution at a material-to-liquid ratio of 1g:50ml. Ultrasonic extraction was carried out for 60 minutes, and three extracts and three filter residues of lycopene were obtained by filtration.

[0032] (2) The primary extract, secondary extract, and triple extract are mixed, concentrate...

Embodiment 3

[0035](1) Wash the fresh peach leaves, steam anti-virus, dry in the shade, crush, and sieve to form peach leaf powder with a particle size of 1-20 μm. Stand by, the peach leaf powder is immersed in the Stand still in the aqueous ethanol solution with a volume ratio of 1:0.6 for 8 hours, heat and extract at 60°C for 2.5 hours, filter to obtain the primary extract of flavonoids and naringenin and the primary filter residue, and the primary filter residue is obtained at a solid-liquid ratio of 1g:45ml , immersed in methanol solution, heated and extracted at 50°C for 3.5h, filtered to obtain the secondary extract of quinic acid and the secondary filter residue, and the secondary filter residue was immersed in petroleum ether solution at a material-to-liquid ratio of 1g:45ml. Under the power of 300W, ultrasonically extract for 50 minutes, and filter to obtain three extracts and three filter residues of lycopene.

[0036] (2) The primary extract, the secondary extract, and the tripl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com