Collagen micro fiber and preparation method thereof

A technology of collagen and collagen protein, applied in the field of materials, can solve problems such as long hemostasis time, wound infection and suppuration, wound adhesion, etc., achieve the effect of qualified heavy metal content, simplified preparation process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Removal of non-collagen components in raw materials

[0049] 1. The pigskins that have just been slaughtered are collected by special personnel from the slaughterhouses under standardized management, and the contact with pollutants should be avoided as far as possible, and the pigskins should be frozen and stored immediately after collection;

[0050] 2. After the frozen material is thawed, it is fully cleaned, and the part that is not suitable for processing is removed at the same time;

[0051] 3. Use 2% acetic acid by mass to soak the thawed raw materials for 10 hours. The temperature of the solution is controlled at about 10°C. The purpose is to destroy the cell structure, remove cells and non-collagen protein structures; use the processed raw materials The PBS buffer solution with a pH value of 7.4 was soaked and washed for 60 minutes, so that the final pH value was 7.4;

[0052] 4. After cleaning the raw materials, use 0.6g / 100ml of surfactant TrironX-100 aque...

Embodiment 2

[0062] 1. Removal of non-collagen components in raw materials

[0063] 1. The pigskins that have just been slaughtered are collected by special personnel from the slaughterhouses under standardized management, and the contact with pollutants should be avoided as far as possible, and the pigskins should be frozen and stored immediately after collection;

[0064] 2. After the frozen material is thawed, it is fully cleaned, and the part that is not suitable for processing is removed at the same time;

[0065] 3. Use 3% acetic acid by mass to soak the thawed raw materials for 5 hours. The temperature of the solution is controlled at about 10°C. The purpose is to destroy the cell structure, remove cells and non-collagen protein structures; use the processed raw materials The PBS buffer solution with a pH value of 7.4 was soaked and washed for 60 minutes, so that the final pH value was 7.4;

[0066] 4. After washing the raw materials, use 1g / 100ml TrironX-100 solution to soak for 4...

Embodiment 3

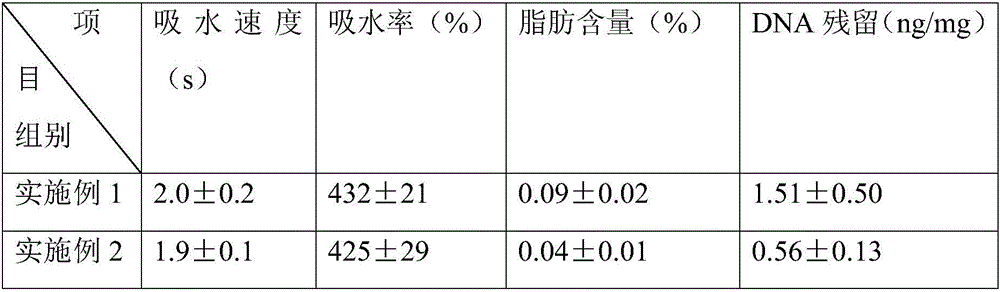

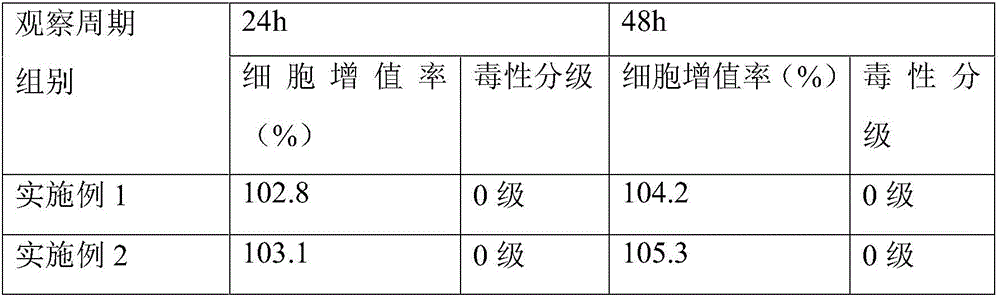

[0075] Embodiment 3: Physical and chemical property detection of collagen microfibrils

[0076] 1. Water absorption rate and water absorption speed test

[0077] Get the sample after freeze-drying prepared by embodiment 1, embodiment 2 respectively, about 100mg, weighing m 1 , accurate to 0.001g. Then add it to a flat plate with excess physiological saline, and record the time when the sample is completely absorbed with water, that is, the water absorption speed. Then use filter paper to absorb excess water on the surface of the sample, and weigh m 2 . Calculate the ratio of the absorbed water weight to the sample weight, repeat the measurement 5 times, and obtain the average value to obtain the water absorption rate of the collagen microfibrils relative to its own weight (Formula 1). The specific results are shown in Table 1.

[0078] Water absorption = (m 2 -m 1 ) / m 1 *100% (1)

[0079] It can be found that the water absorption speed and water absorption rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com