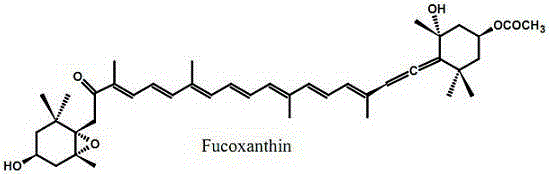

Preparation technology of high purity fucoxanthin

A fucoxanthin and high-purity technology, which is applied in the field of fucoxanthin extraction and purification, can solve the problems of high cost, expensive equipment, and high price, so as to avoid unnecessary losses, save time and manpower, and reduce The effect of purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Crush the dried wakame into dry wakame powder (50-100 mesh);

[0030] (2) Take 100g of dried wakame powder, add 1.5L of 70% ethanol aqueous solution, stir evenly, and stand at 40°C for 12.0h in the dark;

[0031] (3) Suction filter the seaweed extract, extract the residue a second time according to the operation of step (2), and finally discard the residue, and mix the algae powder extract twice;

[0032] (4) Pretreat the AB-8 resin with 75% ethanol aqueous solution for 24 hours, then fully rinse with distilled water, then rinse the AB-8 resin with 75% ethanol solution for 3~4 times, so that the resin is immersed in 75% ethanol aqueous solution, and finally the AB-8 macroporous adsorption resin is wet-packed, and 75% ethanol aqueous solution is balanced;

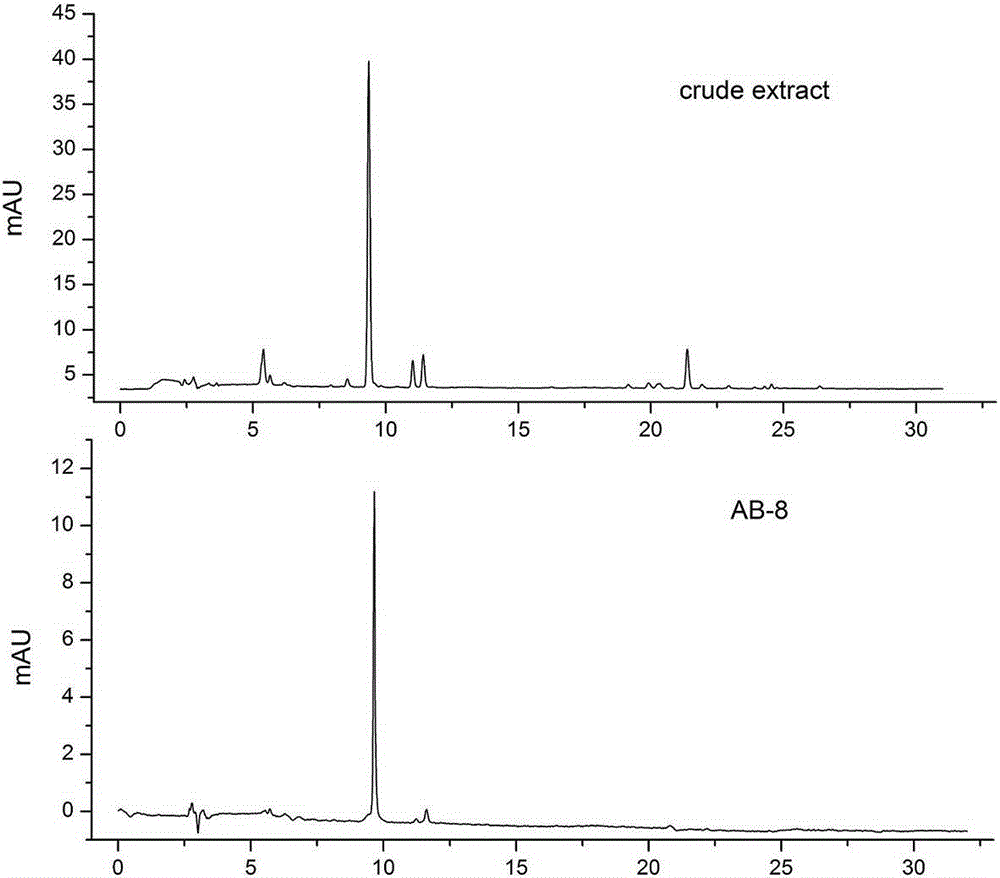

[0033] (5) Load the sample extract at a rate of 0.5BV / h, desorb with absolute ethanol at a rate of 1.0BV / h, collect the eluate continuously, and perform HPLC chromatographic analysis;

[0034] (6) Concentrate th...

Embodiment 2

[0037] (1) 3kg of dried wakame is crushed into dry wakame powder;

[0038] (2) Add 45L of 75% ethanol aqueous solution into a 50L reaction vessel, add the dry wakame powder into it, stir for 30min, and extract at 45°C in the dark for 16h;

[0039] (3) Suction and filter the seaweed extract, repeat the extraction of the residue, the same as step (2), and finally mix the two extracts;

[0040] (4) Pretreat the AB-8 resin according to the steps in (4) in Example 1, and wet-pack the column (10×75cm), the column height after equilibrium is 56cm, and the volume of 1 column is 4.4L;

[0041] (5) Automatically load the sample at a speed of 70ml / min, elute with absolute ethanol, collect the orange eluate and mix it evenly, and analyze it by HPLC;

[0042] (6) Concentrate the eluent under reduced pressure below 40°C to a certain amount, and blow dry with nitrogen to obtain 378g of red paste, containing 10.3g of fucoxanthin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com