Preparation method for producing butyl rubber through polyvinyl alcohol

A polyvinyl alcohol, butyl rubber technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of complex and obvious bonding process, and cannot use rollers, etc., and achieve the bonding process. The effect of simplicity, improved bonding strength, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

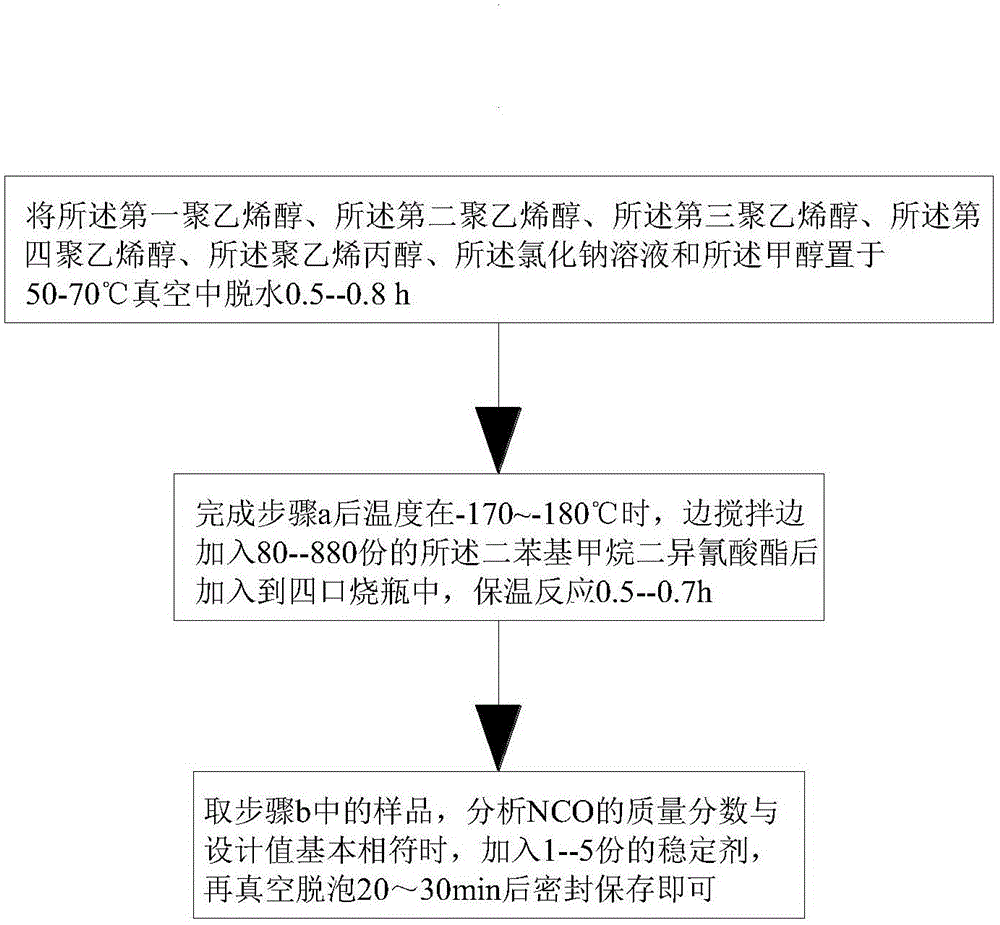

[0021] Such as figure 1 shown, including the following steps:

[0022] a, the first polyvinyl alcohol, the second polyvinyl alcohol, the third polyvinyl alcohol, the fourth polyvinyl alcohol, the polyvinyl propanol, the sodium chloride solution and the The methanol is dehydrated in a vacuum at 50-70°C for 0.5-0.8h;

[0023] b. After completing step a, when the temperature is -170--180°C, add 80-880 parts of the diphenylmethane diisocyanate while stirring, and then add it into a four-necked flask, and keep it warm for 0.5-0.7h;

[0024] c. Take the sample in step b, analyze that the mass fraction of NCO is basically consistent with the design value, add 1-5 parts of stabilizer, and vacuum defoam for 20-30 minutes, then seal and store.

[0025] Preferably in the present invention, the first polyvinyl alcohol accounts for 639 parts; the second polyvinyl alcohol accounts for 559 parts; the third polyvinyl alcohol accounts for 445 parts; the fourth polyethylene Alcohol accounts ...

Embodiment 2

[0027] Such as figure 1 shown, including the following steps:

[0028] a, the first polyvinyl alcohol, the second polyvinyl alcohol, the third polyvinyl alcohol, the fourth polyvinyl alcohol, the polyvinyl propanol, the sodium chloride solution and the The methanol is dehydrated in a vacuum at 50-70°C for 0.5-0.8h;

[0029] b. After completing step a, when the temperature is -170--180°C, add 80-880 parts of the diphenylmethane diisocyanate while stirring, and then add it into a four-necked flask, and keep it warm for 0.5-0.7h;

[0030] c. Take the sample in step b, analyze that the mass fraction of NCO is basically consistent with the design value, add 1-5 parts of stabilizer, and vacuum defoam for 20-30 minutes, then seal and store.

[0031] Preferably in the present invention, the first polyvinyl alcohol accounts for 609 parts; the second polyvinyl alcohol accounts for 509 parts; the third polyvinyl alcohol accounts for 395 parts; the fourth polyethylene Alcohol accounts ...

Embodiment 3

[0033] Such as figure 1 shown, including the following steps:

[0034] a, the first polyvinyl alcohol, the second polyvinyl alcohol, the third polyvinyl alcohol, the fourth polyvinyl alcohol, the polyvinyl propanol, the sodium chloride solution and the The methanol is dehydrated in a vacuum at 50-70°C for 0.5-0.8h;

[0035] b. After completing step a, when the temperature is -170--180°C, add 80-880 parts of the diphenylmethane diisocyanate while stirring, and then add it into a four-necked flask, and keep it warm for 0.5-0.7h;

[0036] c. Take the sample in step b, analyze that the mass fraction of NCO is basically consistent with the design value, add 1-5 parts of stabilizer, and vacuum defoam for 20-30 minutes, then seal and store.

[0037] Preferably in the present invention, the first polyvinyl alcohol accounts for 689 parts; the second polyvinyl alcohol accounts for 609 parts; the third polyvinyl alcohol accounts for 495 parts; the fourth polyethylene Alcohol accounts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com