Formate dehydrogenase mutant with improved enzyme activity and stability as well as construction method of formate dehydrogenase mutant

A formate dehydrogenase and mutant technology, applied in the field of genetic engineering, can solve the problems of poor operation stability and low specific enzyme activity, and achieve the effects of improving acid resistance, eliminating resistance, increasing specific enzyme activity and catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Contains the construction of the recombinant vector of formate dehydrogenase mutant

[0029] (1) Obtaining of the A10C mutant: using the nucleotide sequence shown in SEQ ID NO.4 as a template, Fprimer (sequence shown in SEQ ID NO.5) and Rprimer (sequence shown in SEQ ID NO.6) are primers, PCR is performed to obtain the recombinant gene shown in SEQ ID NO.3.

[0030] (2) Combine the recombinant gene with pET28a They were digested with EcoR I and Xho I respectively, and ligated with T4 DNA ligase overnight at 16°C after purification. The ligation product was chemically transformed into E.coli BL21 competent cells. The transformation solution was applied to an LB plate containing kanamycin (50mg / L), the plasmid was extracted, and the recombinant plasmid constructed was verified by double enzyme digestion, which was named pET28a-A10C. The sequencing work was completed by Shanghai Sangong.

Embodiment 2

[0031] Example 2 Production of Formate Dehydrogenase Mutant Recombinant Escherichia coli Engineering Bacteria Construction

[0032] The strain containing the correct recombinant plasmid pET28a-A10C obtained in Example 1 is the recombinant genetically engineered strain pET28a-A10C / E.coli BL21 of the present invention.

Embodiment 3

[0033] Example 3 Recombinant strain pET28a-A10C / E.coliBL21 expresses formate dehydrogenase and assays its enzyme activity

[0034] The recombinant strain pET28a-A10C / E.coli BL21 constructed in Example 2 and the control strain pET28a-FDH / E.coli BL21 expressing the unmutated wild enzyme CboFDH (amino acid sequence shown in SEQ ID NO: 2) were respectively inoculated in In 10 mL of LB medium containing kanamycin, shake culture at 37°C overnight, transfer to TY fermentation medium at 4% inoculum size the next day, culture at 37°C for 4 hours, add 0.5mM IPTG and induce at 24°C for 16 Hour. The cells were collected by centrifugation and broken, and the cell broken supernatant (crude enzyme solution) was used for the determination of enzyme activity.

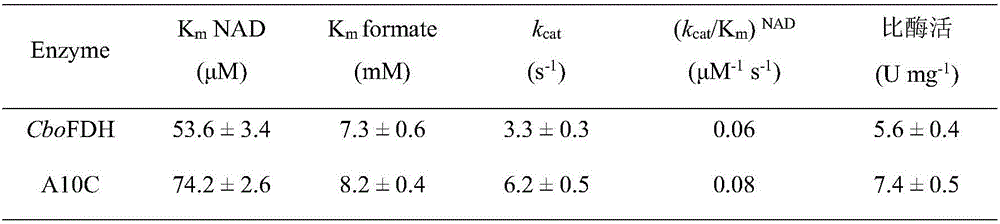

[0035] The obtained crude enzyme liquid was purified to obtain the formate dehydrogenase mutant A10C, and the kinetic parameters of the purified recombinant formate dehydrogenase mutant A10C were analyzed, as shown in Table 1. + Affin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com