Method for preparing nanostructured bioactive oxide film on titanium alloy surface

A bioactive, nanostructured technology, applied in tissue regeneration, metal material coating process, prosthesis, etc., can solve the problem that the oxide layer does not have cell response ability, and achieve good cell response ability, biological activity, and good adhesion ability. , The effect of the process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

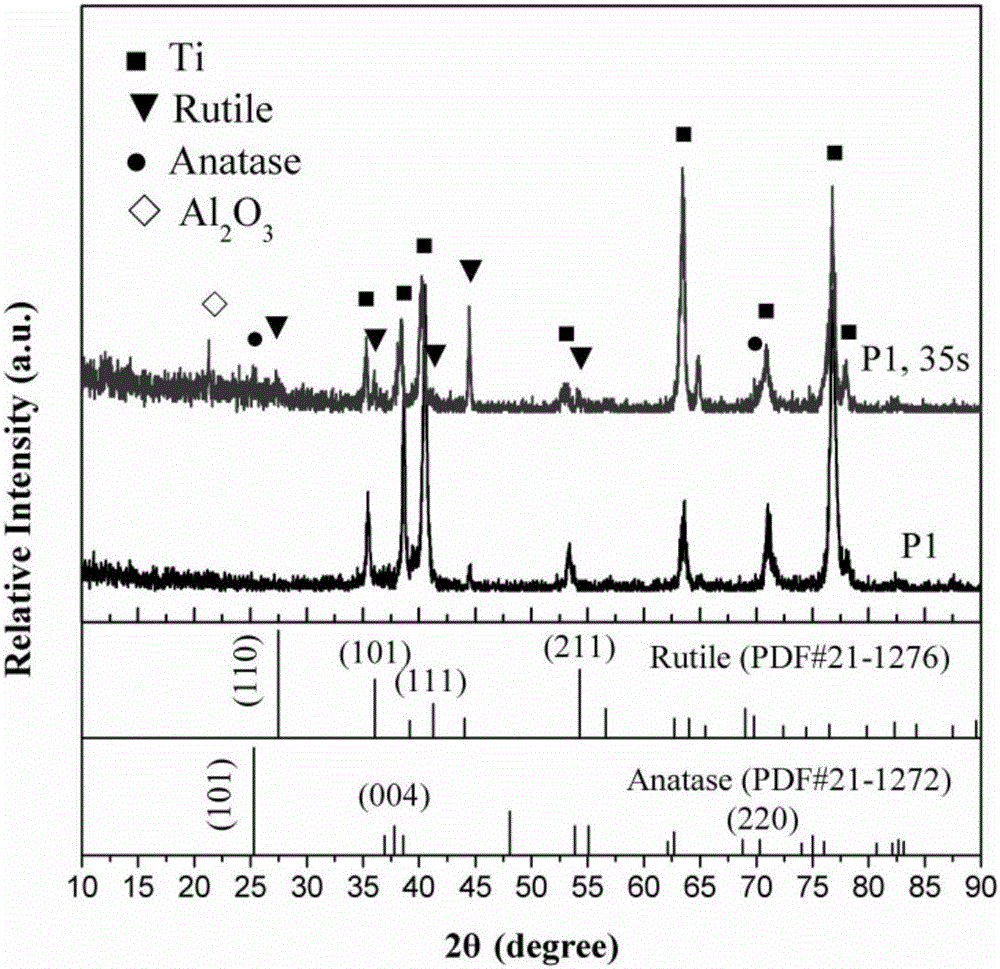

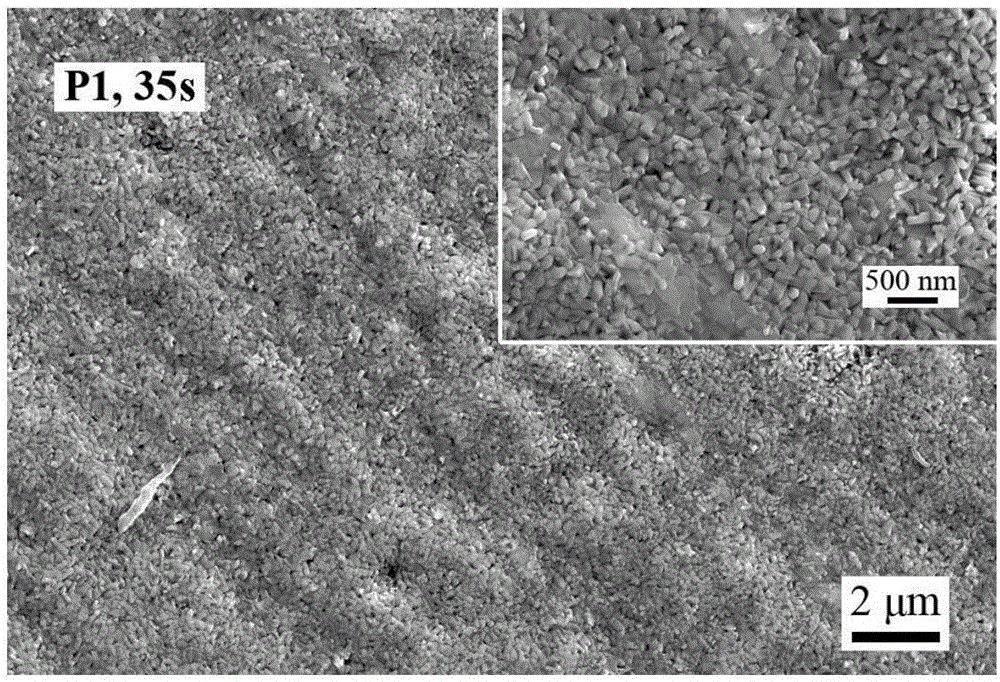

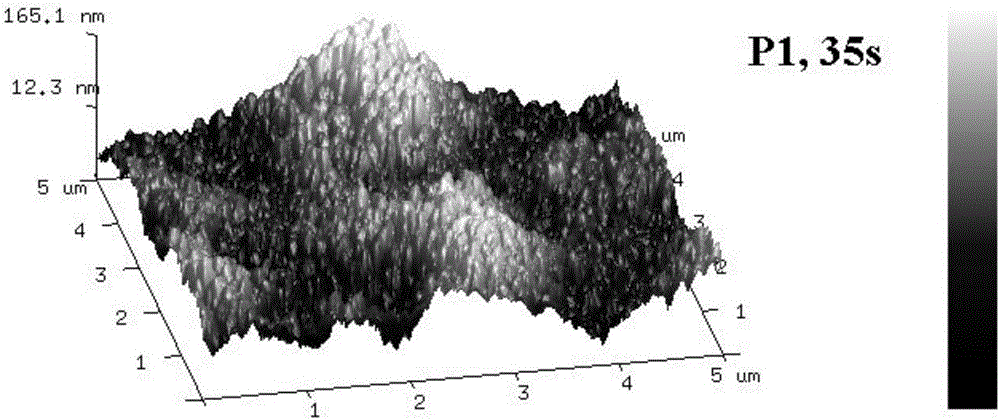

Embodiment 1

[0047] 1. Titanium alloy (Ti6Al4V) samples were polished with 240#, 400#, 600# and 1000# SiC sandpaper in sequence, then ultrasonically cleaned with acetone, deionized water and alcohol in sequence, and then heated at 40°C Dry at high temperature for 24h;

[0048] 2. The titanium alloy sample dried in step (1) was subjected to ultrasonic shot peening treatment for 100s by ultrasonic shot peening equipment with a power of 1800W, an amplitude of 30μm, and a frequency of 20KHz. Ultrasonic cleaning for 5 minutes, and finally drying at 35°C for 6 hours; the diameter of the pellets used is D 丸 =1.5mm, the material of the shot is 304 cast steel, the hardness of the shot is 55HRC, and the speed of the shot is 20m / s during shot peening;

[0049] 3. Place the titanium alloy sample after step (2) ultrasonic shot peening in the induction coil of a super-audio frequency induction heating device with a rated power of 60kW, and add ferrite magnetizers on both sides of the induction coil; to...

Embodiment 2

[0053] 1. Titanium alloy (Ti6Al4V) samples were polished with 240#, 400#, 600# and 1000# SiC sandpaper in sequence, then ultrasonically cleaned with acetone, deionized water and alcohol in sequence, and then heated at 40°C Dry at high temperature for 24h;

[0054] 2. The titanium alloy sample dried in step (1) was subjected to ultrasonic shot peening treatment for 100 s by ultrasonic shot peening equipment with a power of 2200 W, an amplitude of 40 μm, and a frequency of 20 KHz, and after continuous stirring and soaking for 90 s, take out distilled water and alcohol. Ultrasonic cleaning for 5 minutes, and finally drying at 35°C for 6 hours; the diameter of the pellets used is D 丸 =1.5mm, the material of the shot is 304 cast steel, the hardness of the shot is 55HRC, and the speed of the shot during shot peening is 18m / s;

[0055] 3. Place the titanium alloy sample after step (2) ultrasonic shot peening in the induction coil of a super-audio frequency induction heating device w...

Embodiment 3

[0057] 1. Titanium alloy (Ti6Al4V) samples were polished with 240#, 400#, 600# and 1000# SiC sandpaper in sequence, then ultrasonically cleaned with acetone, deionized water and alcohol in sequence, and then heated at 40°C Dry at high temperature for 24h;

[0058] 2. The titanium alloy sample dried in step (1) was subjected to ultrasonic shot peening treatment for 100s by ultrasonic shot peening equipment with a power of 1800W, an amplitude of 30μm, and a frequency of 20KHz. Ultrasonic cleaning for 5 minutes, and finally drying at 35°C for 6 hours; the diameter of the pellets used is D 丸 =1.5mm, the material of the shot is 304 cast steel, the hardness of the shot is 55HRC, and the speed of the shot during shot peening is 23m / s;

[0059] 3. Place the titanium alloy sample after step (2) ultrasonic shot peening in the induction coil of a super-audio frequency induction heating device with a rated power of 60kW, and add ferrite magnetizers on both sides of the induction coil; to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com