Development of novel concentrated turning wheel and application thereof in treatment of VOCs

A concentrating runner and runner technology, applied in gas treatment, fiber type, fiber treatment, etc., can solve the problems of increased operating costs, inconvenience of operation, short service life, huge equipment, etc., and achieve fast exchange and elution speed , fast adsorption speed and improved processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

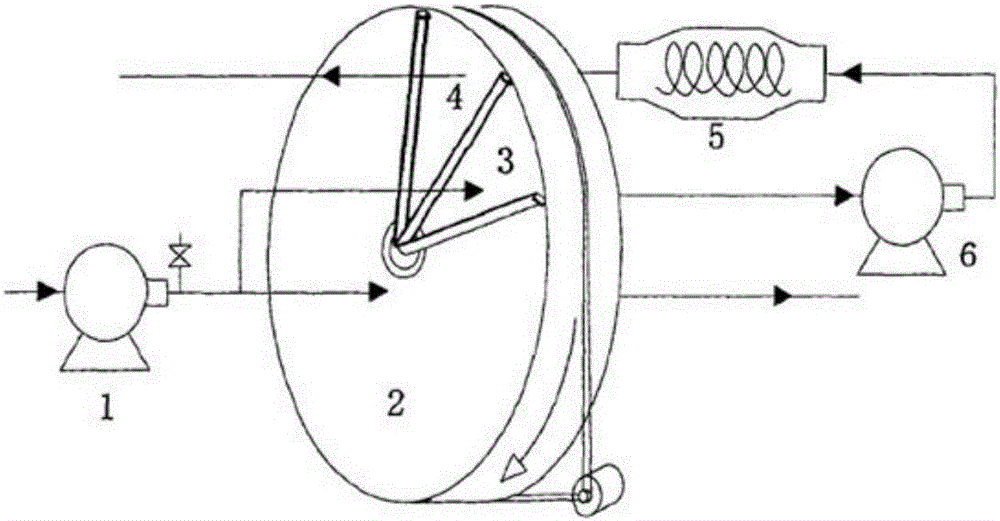

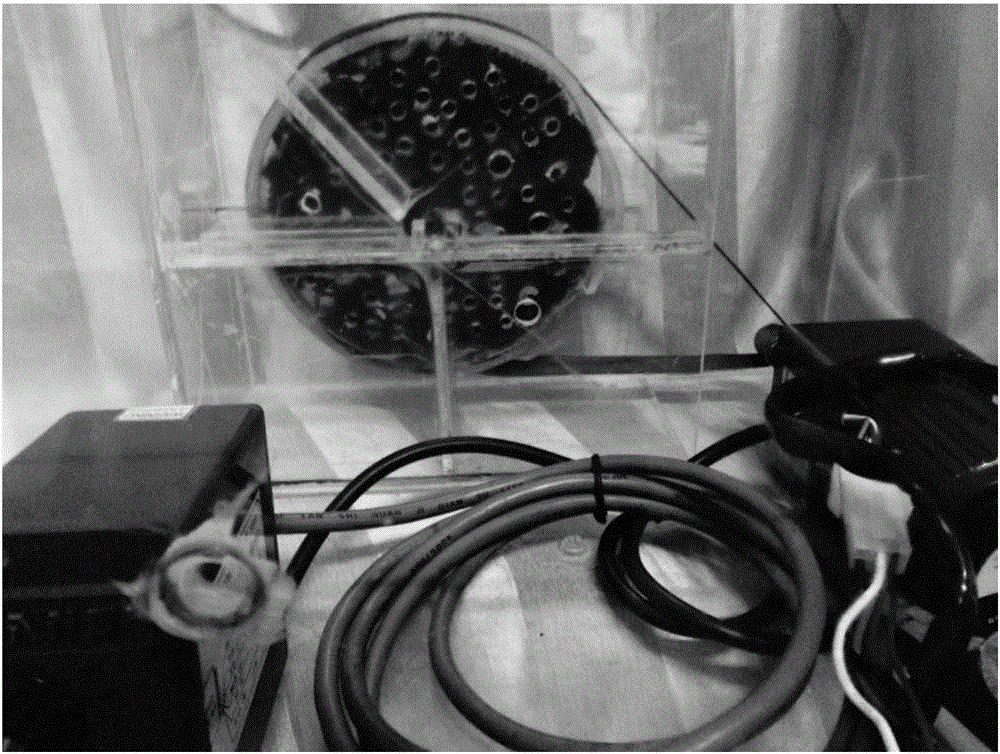

[0039] A new type of enrichment wheel uses the self-developed aminated activated carbon fiber material to make the main part of the wheel, uses plexiglass to make the support of the device, functional partitions and protective materials for the main body of the wheel, and uses a frequency conversion gear motor as the concentration wheel Using benzene, toluene, xylene solvents and nitrogen cylinders to complete the simulation of exhaust gas from paint exhaust workshops such as car spray painting and wind power blade baking paint, to investigate the concentration effect of the self-made new runner. At that time, the company undertook the exhaust gas treatment project of a wind power blade painting room in Tianjin, and combined with the project to do this test. Take the test results of toluene as an example: the test process investigated the removal rate of toluene tail gas under different concentration ratios and different rotor speeds.

[0040] First investigate the removal rat...

Embodiment 2

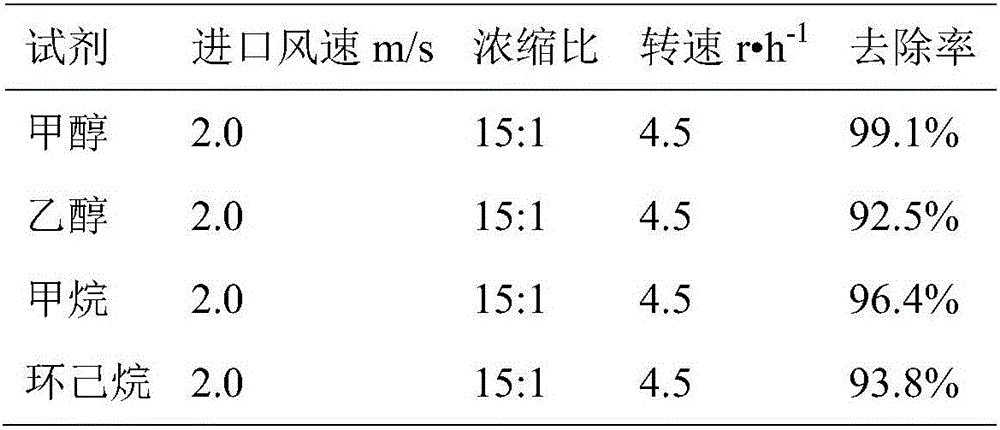

[0043] A new type of enrichment runner uses self-developed sulfonated polypropylene fiber material to make the main part of the runner, uses plexiglass to make the support of the device, functional partitions and protective materials for the main body of the runner, and uses a frequency conversion gear motor as the concentrate runner Using methanol, ethanol, light hydrocarbon solvents and nitrogen cylinders to complete the simulation of exhaust emissions from chemical plants, raw materials, oil refining and other workshops to investigate the concentration effect of the self-made new runner. At that time, the company undertook the tail gas treatment project of a chemical and pharmaceutical company in Linyi, Shandong, and combined with the project to do this test. Take the test results of methanol as an example: the test process also investigated the removal rate of toluene tail gas under different concentration ratios and different rotor speeds. Concrete test plan is the same a...

Embodiment 3

[0052] A new type of enrichment runner adopts self-developed aminated polytetrafluoroethylene fiber material to make the main part of the runner, uses plexiglass to make the support of the device, functional partitions and the protection material of the runner main body, and uses a frequency conversion gear motor as the The driving equipment of the enrichment runner uses methyl mercaptan, ethanethiol reagents and nitrogen cylinders to complete the simulation of odorous exhaust emissions from chemical plants, raw materials and other workshops to investigate the concentration effect of the self-made new runner. At that time, the company undertook the odorous tail gas treatment project of a three-waste treatment enterprise in Tianjin Refining and Chemical Co., Ltd., and combined with the project to do this test. Take the test results of methyl mercaptan as an example: the test process also investigated the removal rate of toluene tail gas under different concentration ratios and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com