Method for preparing KNb3O8 nanowire through laser inducing

A laser-induced, nanowire technology, used in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve problems such as nanostructure blanks, and achieve the effects of simple equipment, rich morphologies, and high aspect ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

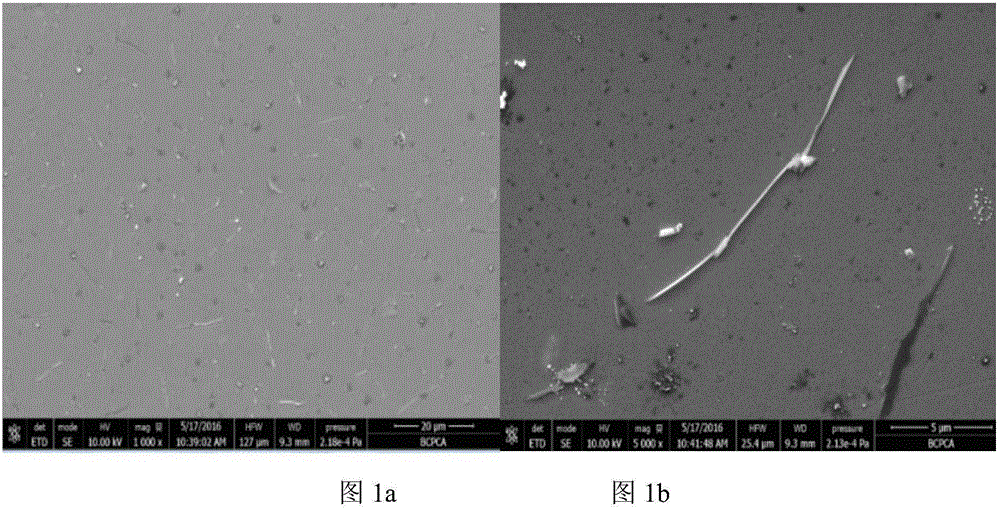

[0034] Weigh 2.0g (7.5mmol) of niobium pentoxide powder, then dissolve 43.6682 g of KOH crystals into 30 mL of water to prepare a potassium hydroxide solution with a concentration of 25mol / L, and use a magnetic stirrer to fully dissolve it ; The ground niobium pentoxide powder will be weighed and added to the prepared 25mol / L potassium hydroxide alkaline solution, fully stirred with a magnetic stirrer to make it fully mixed; In the container, irradiate with laser light for 4 min. After the experiment, the substrate was taken out from the solution, washed several times with deionized water, and KNb 3 o 8 One-dimensional nanostructures.

Embodiment 2

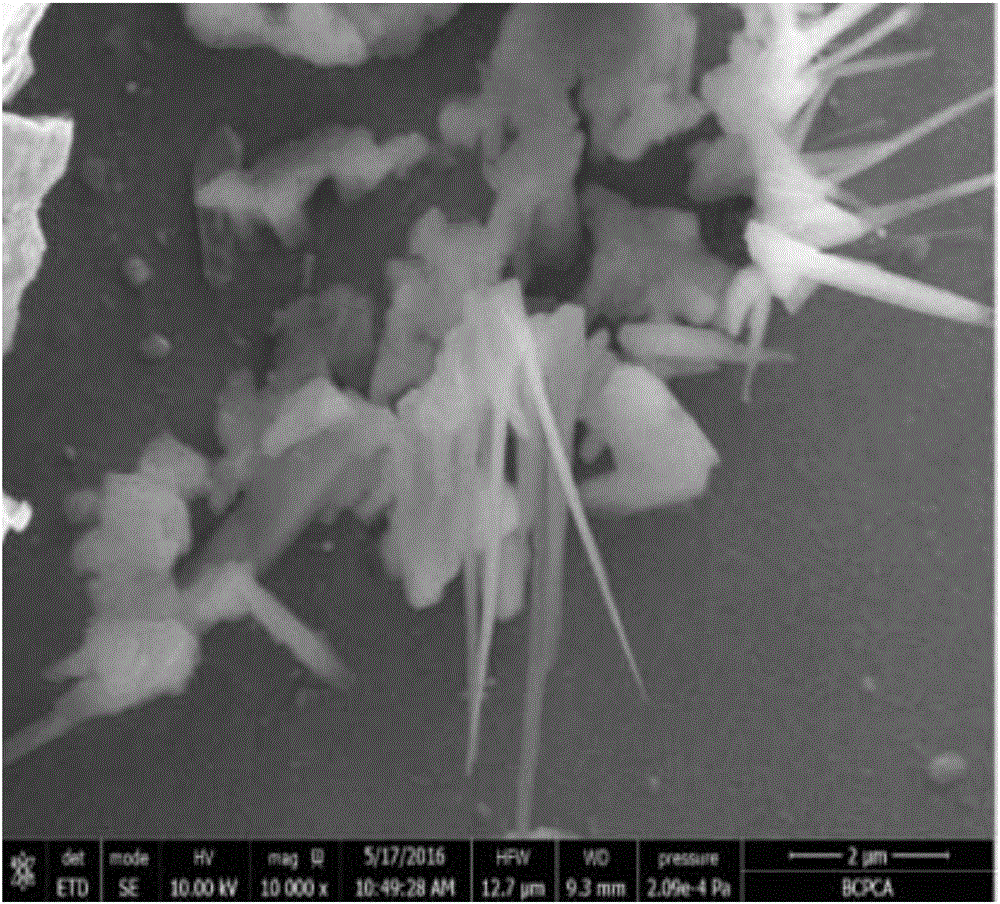

[0036] Weigh 2.0g (7.5mmol) of niobium pentoxide powder, then dissolve 43.6682 g of KOH crystals into 30 mL of water to prepare a potassium hydroxide solution with a concentration of 25mol / L, and use a magnetic stirrer to fully dissolve it ; The ground niobium pentoxide powder will be weighed and added to the prepared 25mol / L potassium hydroxide alkaline solution, fully stirred with a magnetic stirrer to make it fully mixed; In the container, irradiate with laser light for 6 min. After the experiment, the substrate was taken out from the solution, washed several times with deionized water, and KNb 3 o 8 One-dimensional nanostructures. Comparing Example 2 with Example 1, the nanowires are needle-shaped and relatively long in length. Due to the increase in the number of nanowires, the luminous intensity is slightly higher than that of irradiation for 4 minutes.

Embodiment 3

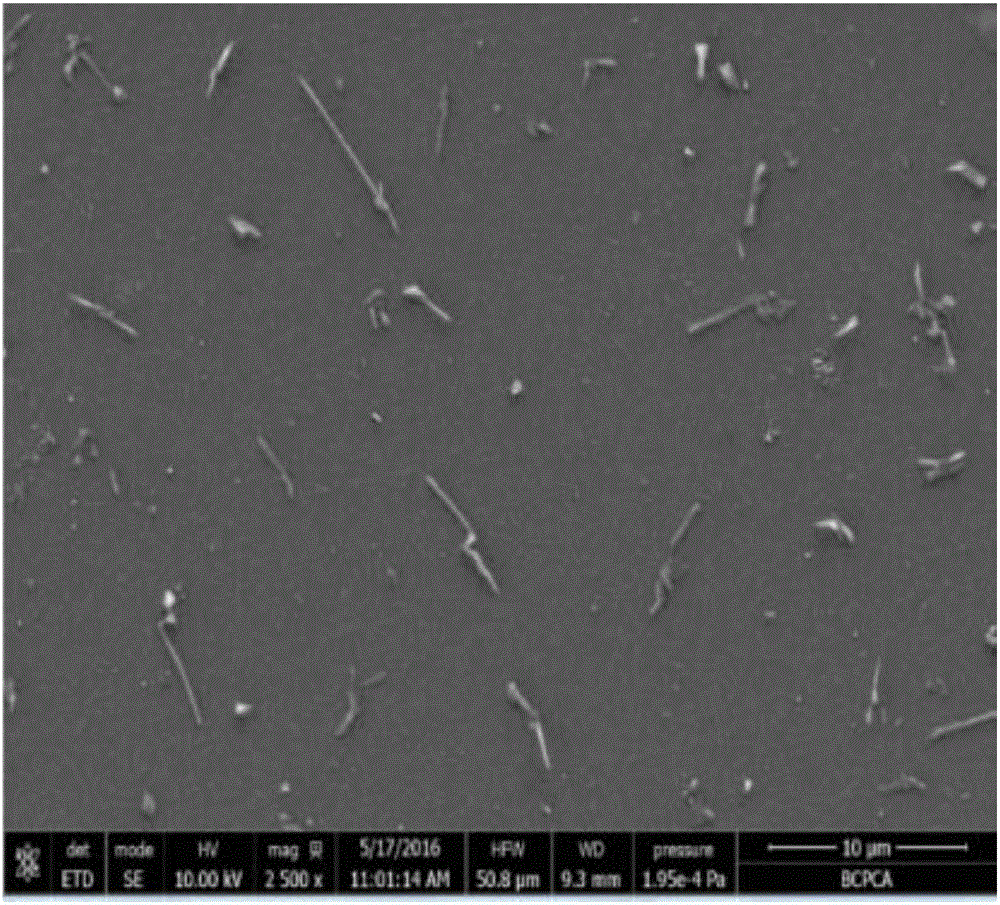

[0038] Weigh 2.0g (7.5mmol) of niobium pentoxide powder, then dissolve 43.6682g of KOH crystals in 30mL of water to prepare a potassium hydroxide solution with a concentration of 25mol / L, and fully dissolve it with a magnetic stirrer; Add the ground niobium pentoxide powder that has been weighed into the prepared 25mol / L potassium hydroxide alkaline solution, and use a magnetic stirrer to stir thoroughly to make it fully mixed; add it to the container that has been placed in the substrate , irradiated with laser light for 8 min. After the experiment, the substrate was taken out from the solution and washed several times with deionized water to obtain KNb 3 o 8 One-dimensional nanostructures. Compared with Example 2, the nanowires are more dispersed, do not grow out of the clusters, and have a longer length. The number of nanowires is more, and the luminous intensity is the largest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com