Preparation method for poly(glycidyl methacrylate) polymer microsphere

A technology of polymethacrylic acid and glycidyl ester, which is applied in the field of functional materials to achieve the effects of uniform appearance, low reaction temperature and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

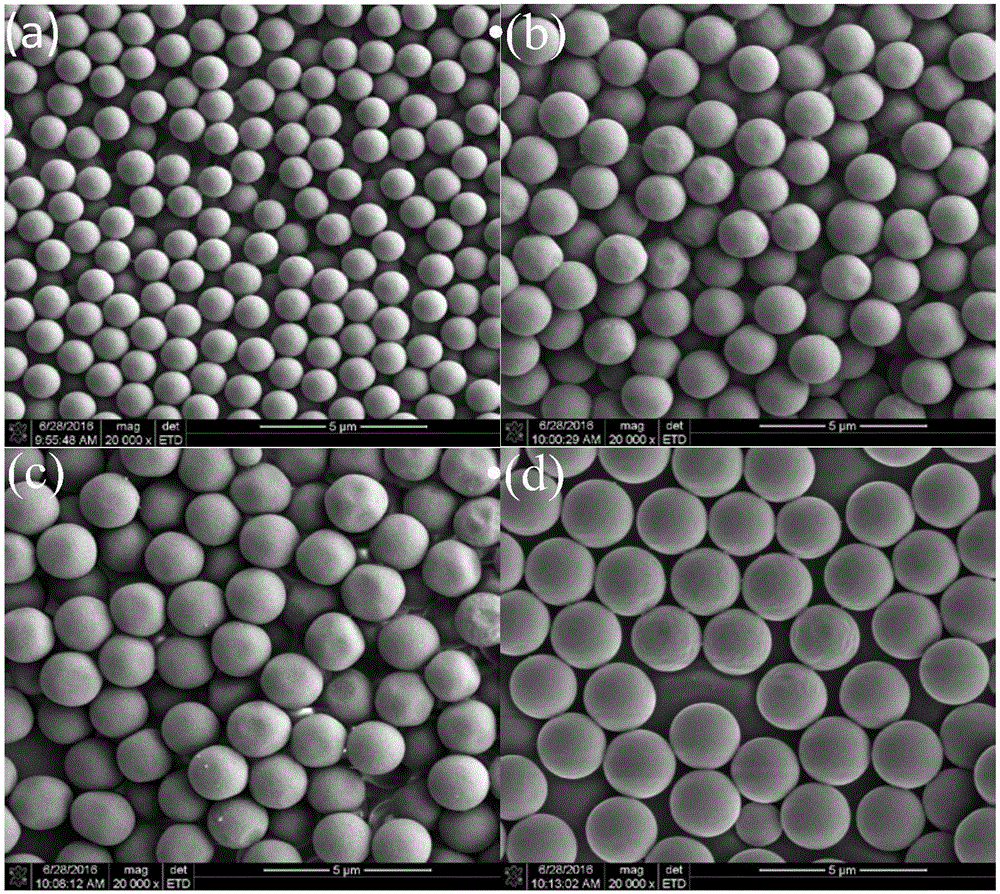

[0031] Preparation of PGMA microspheres with a particle size of 1.0 µm

[0032] (1) Add 90 mL of ethanol and 10 mL of distilled water into a four-neck flask, then add 0.5 g of PVP, and mix and stir until the PVP is completely dissolved.

[0033] (2) Dissolve 0.05 g of the initiator in 1 mL of glycidyl methacrylate, and quickly inject it into the mixed solution in step (1), protect it with nitrogen throughout the process, mix and stir for 0.5 h, and then raise the temperature to 70 oC , reacted for 12 h.

[0034] The initiator is a composite initiator composed of potassium sulfate and azobisisobutyronitrile, and the molar ratio of potassium sulfate and azobisisobutyronitrile is 1:1.

[0035] (3) The product of step (2) was separated by centrifugation, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 24 h to obtain PGMA microspheres.

[0036] Such as figure 1 As shown in (a), the PGMA microspheres prepared in this e...

Embodiment 2

[0038] Preparation of PGMA microspheres with a particle size of 1.5 µm

[0039] (1) Add 90 mL of ethanol and 10 mL of distilled water into a four-neck flask, then add 1.5 g of PVP, and mix and stir until the PVP is completely dissolved.

[0040] (2) Dissolve 0.1 g of the initiator in 3 mL of glycidyl methacrylate, and quickly inject it into the mixed solution in step (1), protect it with nitrogen throughout the process, mix and stir for 0.5 h, and then raise the temperature to 70 oC , Reaction 12h.

[0041] The initiator is a composite initiator composed of potassium sulfate and azobisisobutyronitrile, and the molar ratio of potassium sulfate and azobisisobutyronitrile is 1:1.

[0042] (3) The product of step (2) was separated by centrifugation, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 24 h to obtain PGMA microspheres.

[0043] Such as figure 1 As shown in (b), the PGMA microspheres prepared in this exampl...

Embodiment 3

[0045] Preparation of PGMA microspheres with a particle size of 1.8 µm

[0046] (1) Add 90 mL of ethanol and 10 mL of distilled water into a four-neck flask, then add 3.0 g of PVP, and mix and stir until the PVP is completely dissolved.

[0047] (2) Dissolve 0.2 g of the initiator in 6 mL of glycidyl methacrylate, and quickly inject it into the mixed solution in step (1), protect it with nitrogen throughout the process, mix and stir for 0.5 h, then raise the temperature to 70 oC , reacted for 12 h.

[0048] The initiator is a composite initiator composed of potassium sulfate and azobisisobutyronitrile, and the molar ratio of potassium sulfate and azobisisobutyronitrile is 1:1.

[0049] (3) The product of step (2) was separated by centrifugation, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 24 h to obtain PGMA microspheres.

[0050] Such as figure 1 As shown in (c), the PGMA microspheres prepared in this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com