Four-branched thermo-sensitive polymer and preparation method thereof

A temperature-sensitive polymer and temperature-sensitive monomer technology, which is applied in the fields of polymer chemistry and material chemistry, can solve problems that affect the performance and application range of polymers, are difficult to control, and the terminal functionality of the chain structure is out of control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present application also provides a preparation method of the above-mentioned thermosensitive polymer, comprising the following steps:

[0043] A), under inert gas and anhydrous conditions, react pentaerythritol, acid-binding agent, catalyst and the acylating agent with the structure of formula (II) in a solvent to obtain the initiator with the structure of formula (III);

[0044] B), under the protection of an inert gas, react the initiator, temperature-sensitive monomer, catalyst and complexing agent in a solvent to obtain an active temperature-sensitive polymer with a structure of formula (IV); the temperature-sensitive The neutral monomer is selected from N-isopropylacrylamide, N-propylacrylamide, N-cyclopropylacrylamide, N,N-diethylacrylamide, N-vinylisopropanamide, N-vinyl N-propionamide, N-vinylcaprolactam, N-vinylpyrrolidone, N-acryloylpyrrolidine, N-acryloyl-N'-n-propiperazine, N-(2,2-dimethyl-1,3 One or more of -dioxan-5 alcohol)-acrylamide and N-(2-ethox...

Embodiment 1

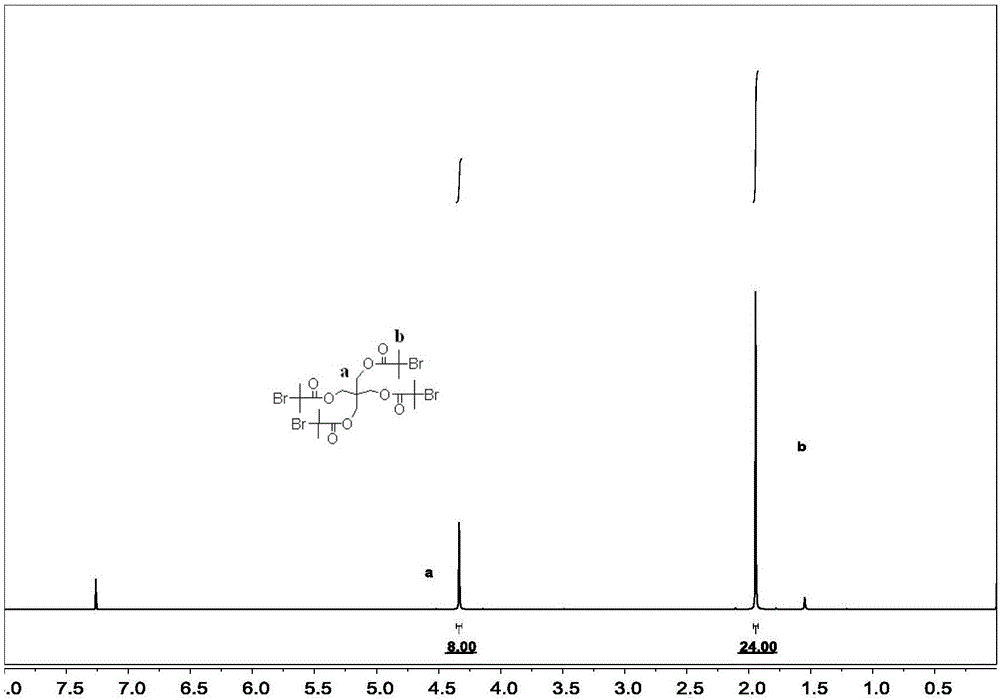

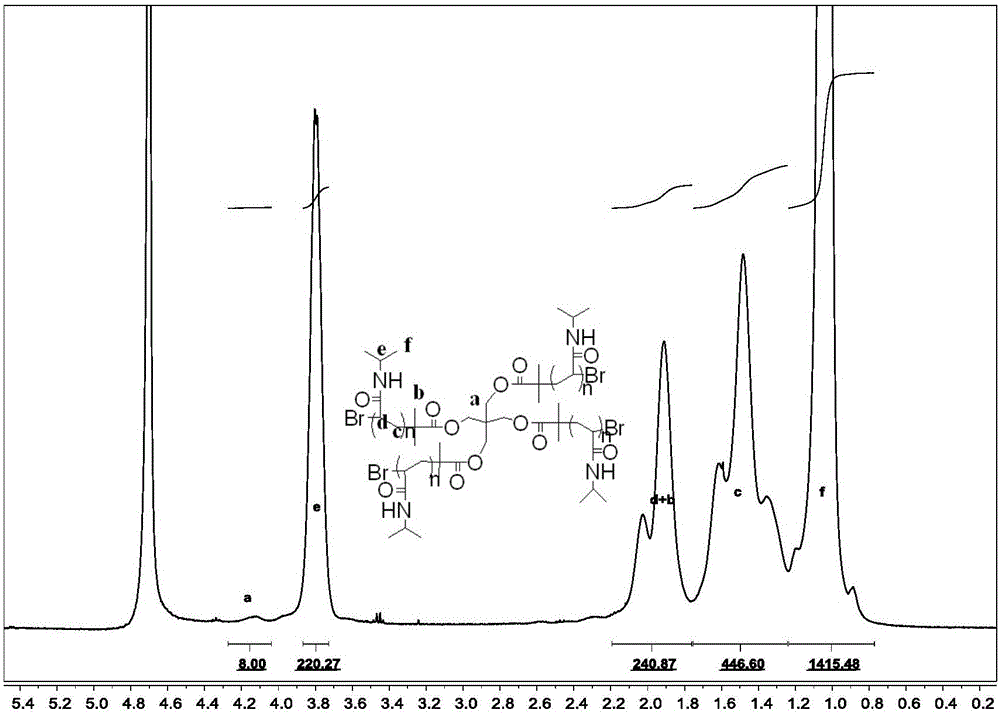

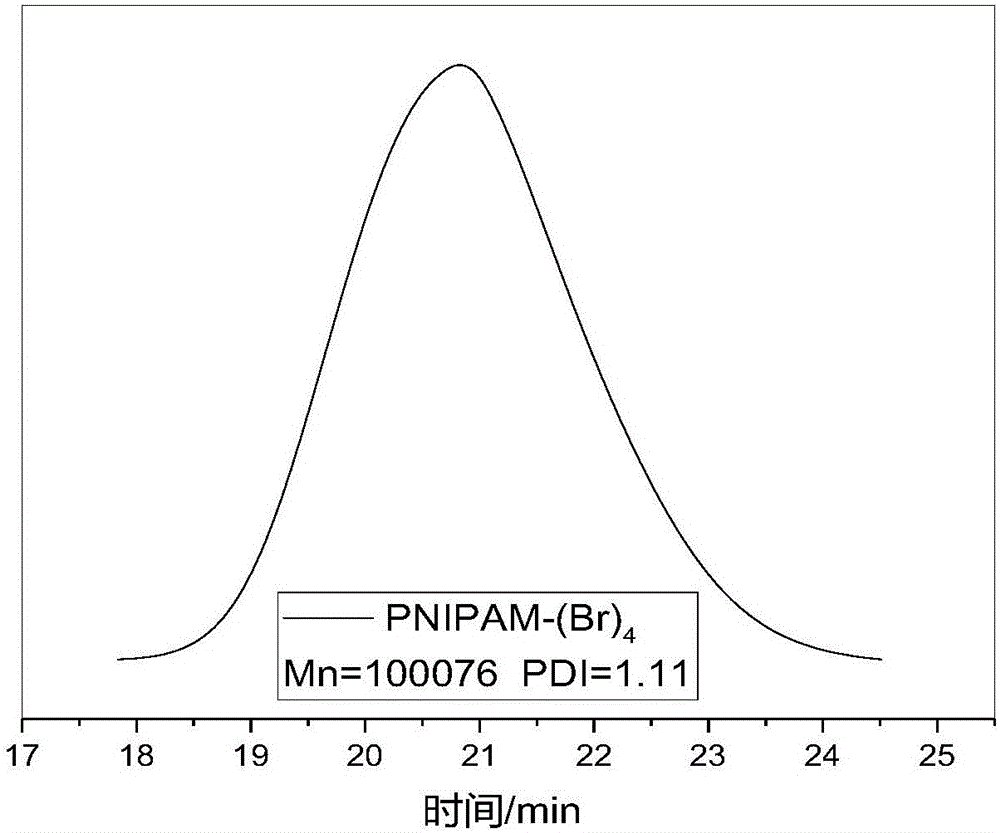

[0071]Add pentaerythritol (0.952g, 7mmol) into a solution containing triethylamine (3.188g, 31.5mmol) and 75ml of dichloromethane, and stir for 30min under ice-bath conditions. 2-Bromoisobutyryl bromide (7.245 g, 31.5 mmol) was slowly added through a constant pressure dropping funnel over 1 hour, and kept at low temperature for 1-2 hours. Then it was gradually raised to room temperature, and the reaction was continued for 12 hours. After the reaction, the obtained product was washed successively with 5% sodium bicarbonate solution (100ml*3), saturated saline (100ml*3), and deionized water (100ml*3). The washed organic layer was rotary evaporated to remove the solvent, dissolved in dichloromethane, slowly added dropwise into glacial ether, and left standing at 0°C for 12 hours. Filter through a funnel and wash with cold diethyl ether (10ml). Dry in a vacuum oven at room temperature to obtain a white crystal tetrakis-(bromoisobutyryl)-pentaerythritol initiator. figure 1 The i...

Embodiment 2

[0077] Add pentaerythritol (0.952g, 7mmol) into a solution containing triethylamine (2.90g, 28.7mmol) and 75ml of dichloromethane, and stir for 30min under ice-bath conditions. 2-Bromoisobutyryl bromide (6.60 g, 28.7 mmol) was added slowly over 1 hour through a constant pressure dropping funnel, and the temperature was kept low for 1-2 hours. Then it was gradually raised to room temperature, and the reaction was continued for 12 hours. After the reaction, the obtained product was washed successively with 5% sodium bicarbonate solution (100ml*3), saturated saline (100ml*3), and deionized water (100ml*3). The washed organic layer was rotary evaporated to remove the solvent, dissolved in dichloromethane, slowly added dropwise into glacial ether, and left standing at 0°C for 12 hours. Filter through a funnel and wash with cold diethyl ether (10ml). At room temperature, dry in a vacuum oven to obtain 2.25 g of white crystal tetrakis-(bromoisobutyryl)-pentaerythritol initiator.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com