A separation method for mixed solid plastics

A separation method and technology for plastics, applied in the field of waste plastic recycling, can solve the problems of expensive instruments, low plastic recycling profits, and low separation efficiency, and achieve the effects of satisfying industrial applications, improving regeneration value, and recycling high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

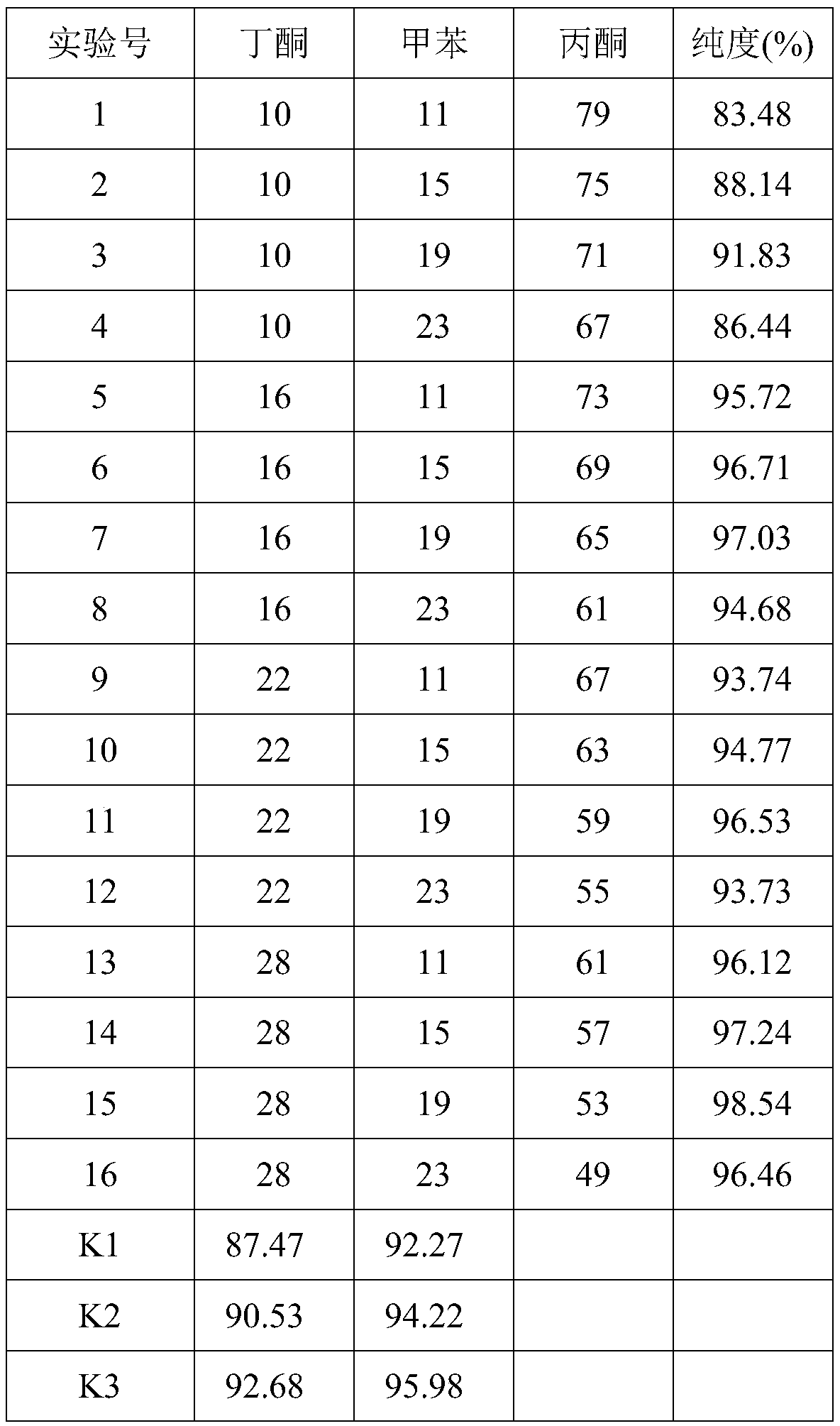

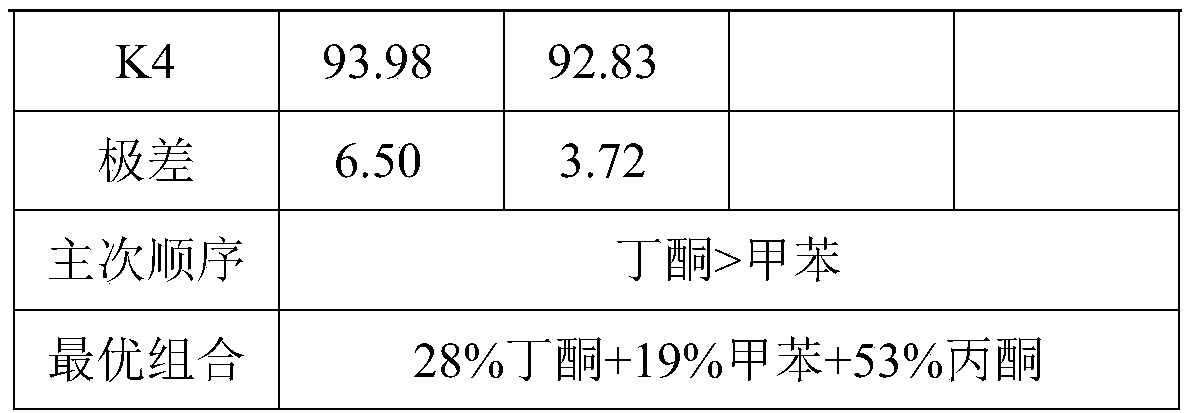

Embodiment 1

[0063] A method for separating mixed solid plastics, the purpose plastics being ABS resins, comprising the following steps:

[0064] 1) prepare solvent, solvent is made up of acetone, butanone and toluene; The mass ratio of acetone, butanone and toluene is 53:28:19;

[0065] 2) Soak the quartz sand particles with a diameter of 1 mm in solvent, and the volume ratio of the solvent to the quartz sand particles is 1:10;

[0066] 3) Stir and mix the quartz sand particles treated in step 2) with the mixed solid plastic at a volume ratio of 1:4, and pass through a sieve to remove excess quartz sand particles attached to the mixed solid plastic;

[0067] 4) The mixed solid plastics treated in step 3) are floated with sodium chloride solution, and the sinking target plastics are collected to complete the separation.

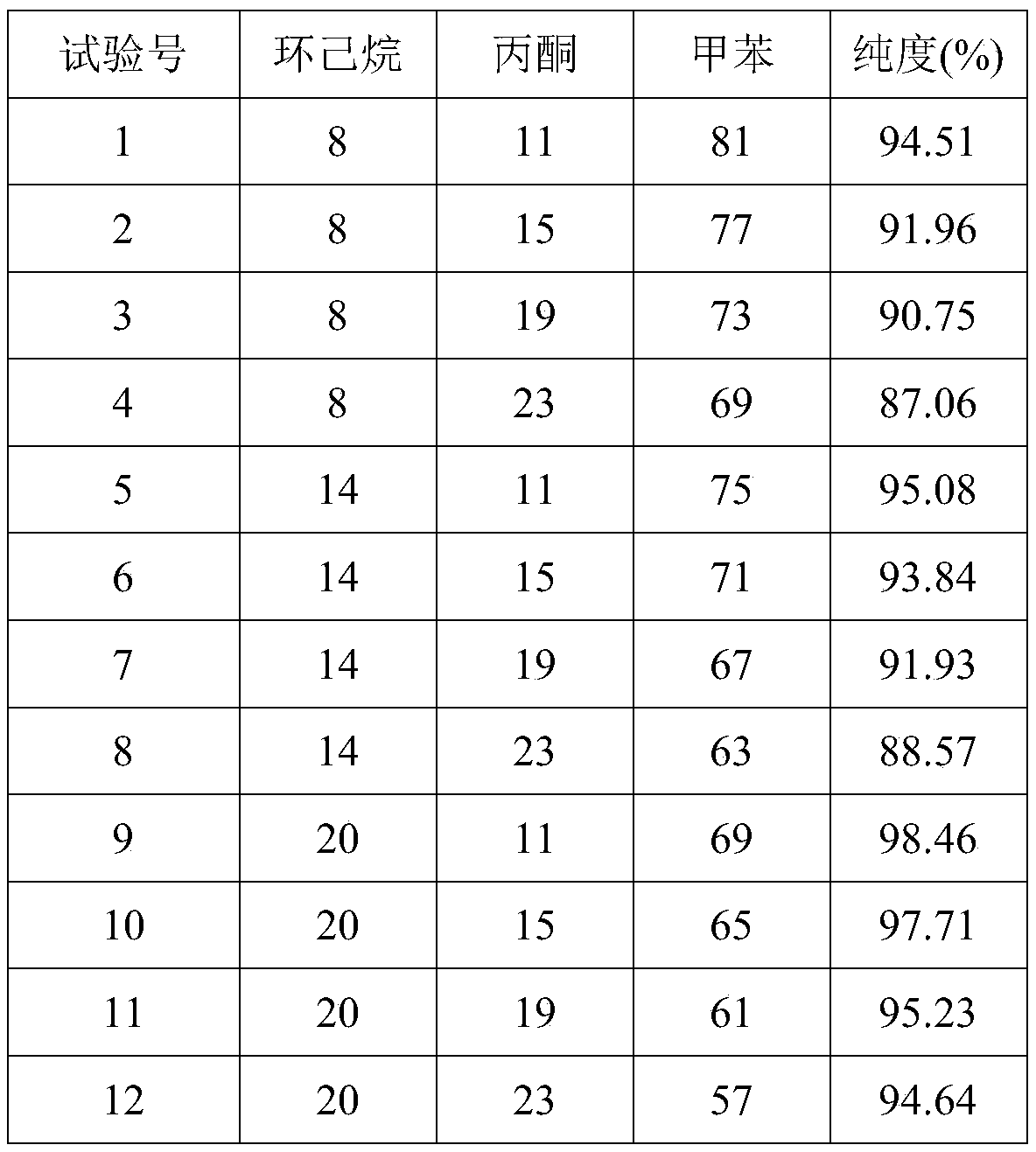

Embodiment 2

[0069] A method for separating mixed solid plastics, the purpose plastics being HIPS resin, comprising the following steps:

[0070] 1) prepare solvent, solvent is made up of acetone, toluene and hexanaphthene; The mass ratio of acetone, toluene and hexanaphthene is 11:63:26;

[0071] 2) Infiltrate the quartz sand particles with a diameter of 1mm into the solvent, and the volume ratio of the solvent to the quartz sand particles is 1:10;

[0072] 3) Stir and mix the quartz sand particles treated in step 2) with the mixed solid plastic at a volume ratio of 1:4, and pass through a sieve to remove excess quartz sand particles attached to the mixed solid plastic;

[0073] 4) The mixed solid plastics treated in step 3) are floated with sodium chloride solution, and the sinking target plastics are collected to complete the separation.

Embodiment 3

[0075] A method for separating mixed solid plastics, the target plastic is PC / ABS alloy, comprising the following steps:

[0076] 1) prepare solvent, solvent is made up of isobutyl acetate, ethyl acetate and cyclohexane by solvent; The mass ratio of isobutyl acetate, ethyl acetate and cyclohexane is 39:18:43;

[0077] 2) soak the glass particles with a diameter of 1mm in the solvent, and the volume ratio of the solvent to the glass particles is 1:10;

[0078] 3) Stir and mix the glass particles treated in step 2) with the mixed solid plastic at a volume ratio of 1:4, and pass through a screen to remove excess glass particles attached to the mixed solid plastic;

[0079] 4) The mixed solid plastics treated in step 3) are floated with a calcium chloride solution, and the sinking target plastics are collected to complete the separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com