A kind of masterbatch with high biochar content and its processing technology

A processing technology and biochar technology, applied in the field of high biochar content masterbatch and its processing technology, can solve the problems of inability to achieve biodegradation, incomplete solution, incomplete degradation, etc., achieve good promotion conditions, and reduce product costs , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0017] Example 1-12: Processing of masterbatches with different material ratios

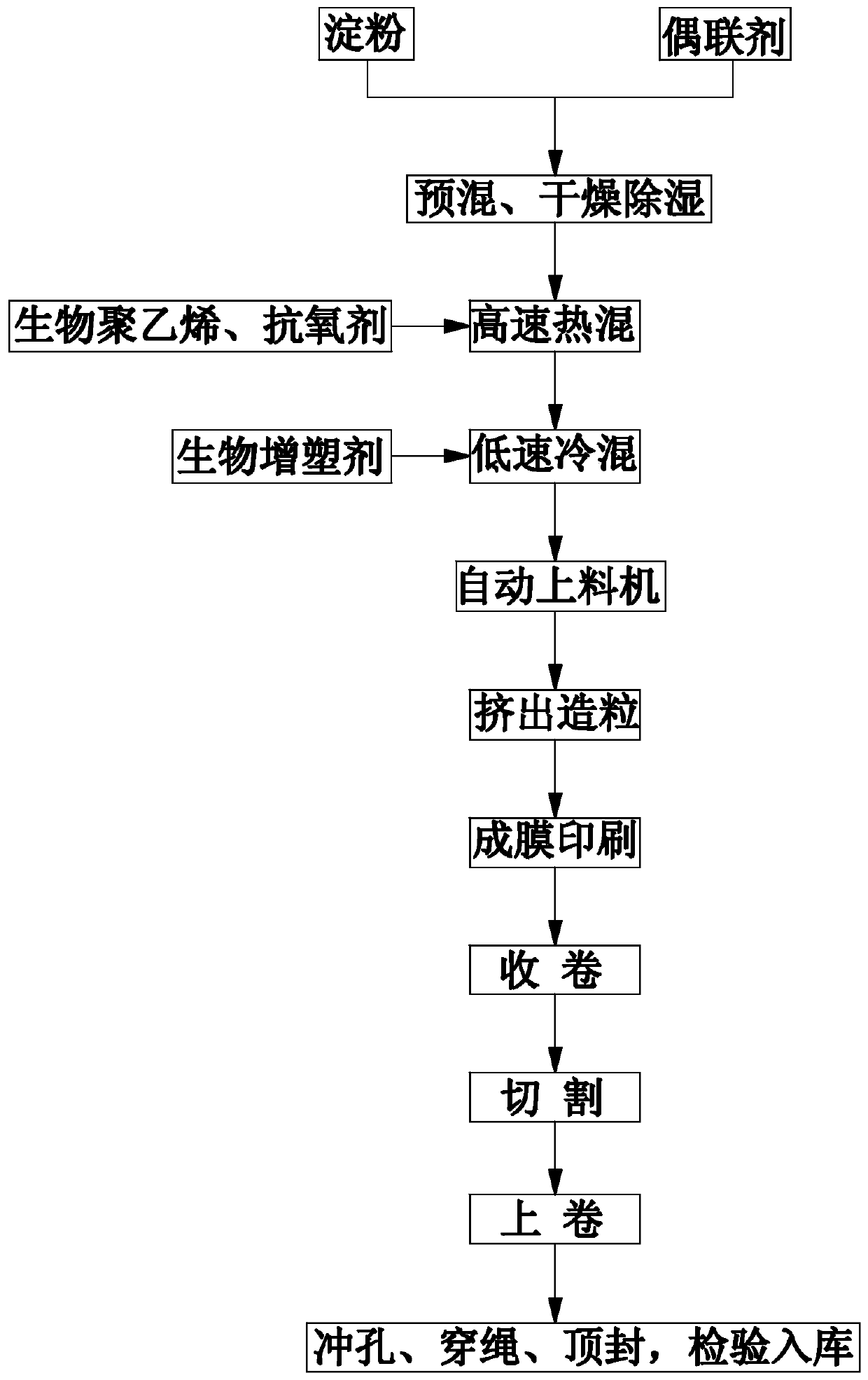

[0018] The production of high biochar content masterbatch in the present embodiment is composed of batching, raw material premixing, dehumidification, hot mixing, cold mixing, extrusion, cooling, molding, inspection and packaging and other steps. The specific process is described as follows:

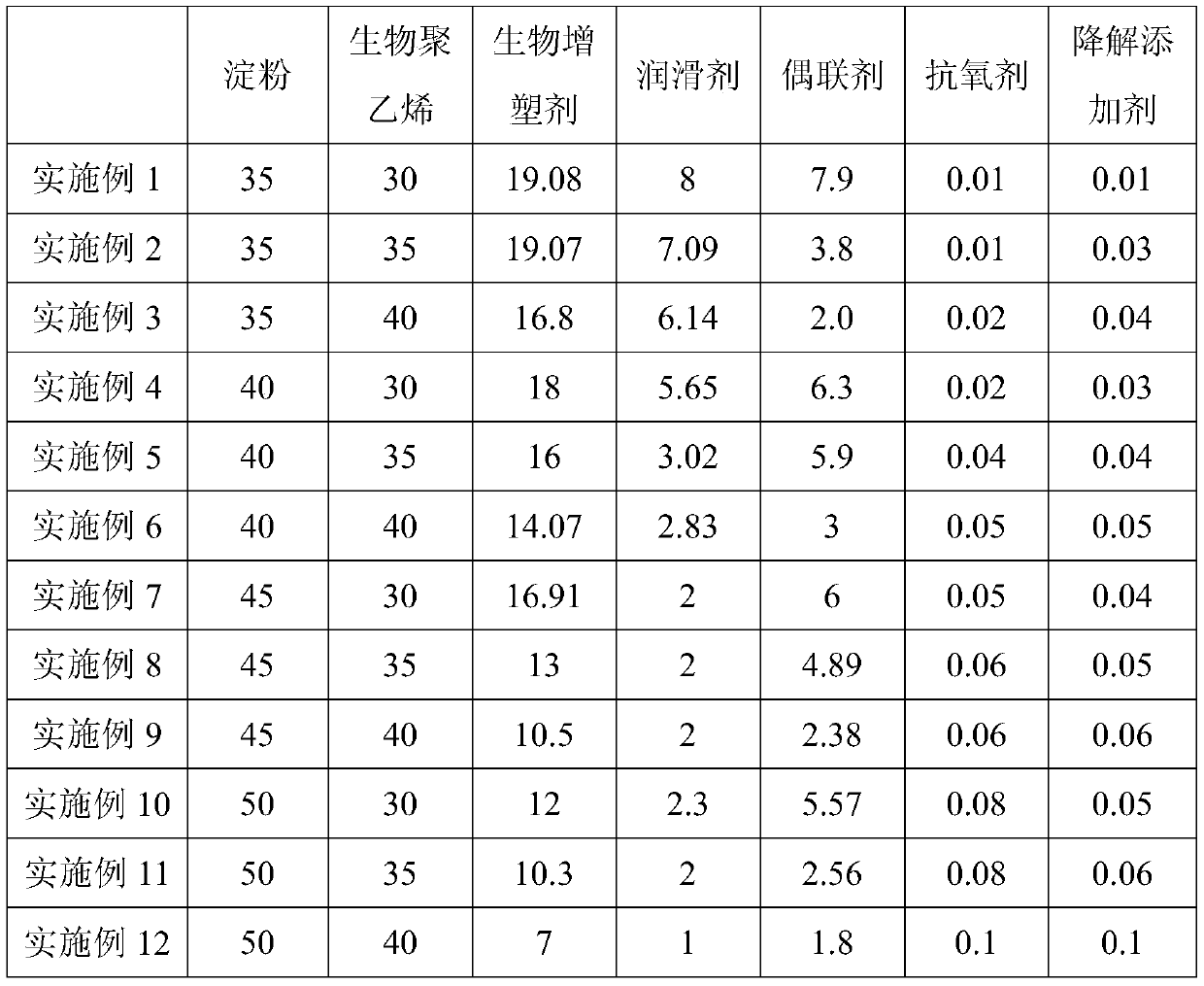

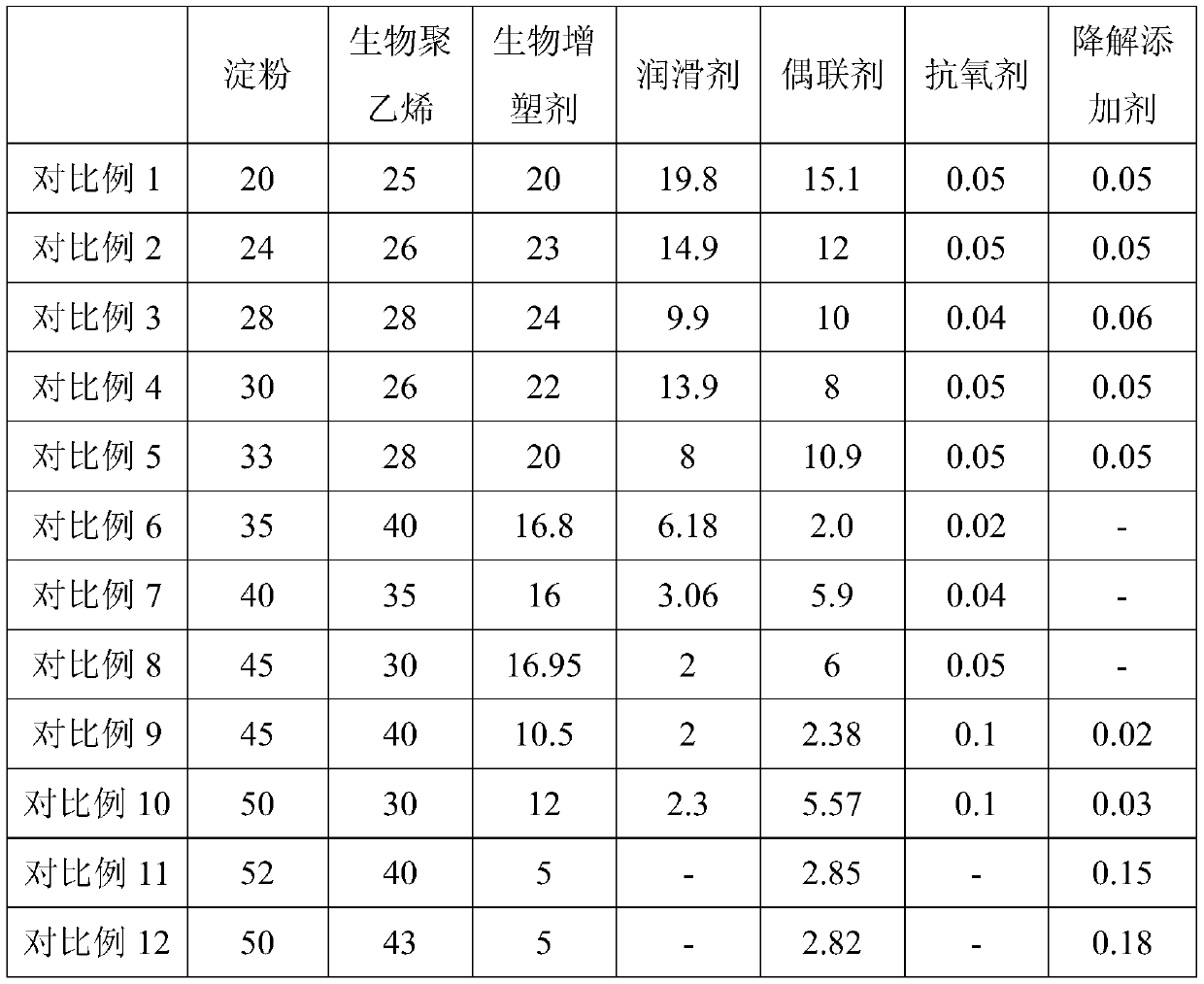

[0019] ①Ingredients: The ingredients are shown in Table 1.

[0020] Table 1 Ingredients list (unit, %)

[0021]

[0022] Among them, edible corn starch (food grade (first-class product), Binzhou Jinhui Corn Development Co., Ltd.) or edible corn starch (food-grade (first-class product), Zhucheng Xingmao Corn Development Co., Ltd.) can be used as starch; biological polyethylene Select gm9450fSlh218 Stn7006 (Brazem); the coupling agent can be selected from isopropyl tristearate titanate (model NDZ-130, Nanjing Shuguang Chemical Group Co., Ltd.) or isopropyl tristearate titanate (Nanjing Shuguang Chemical G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com