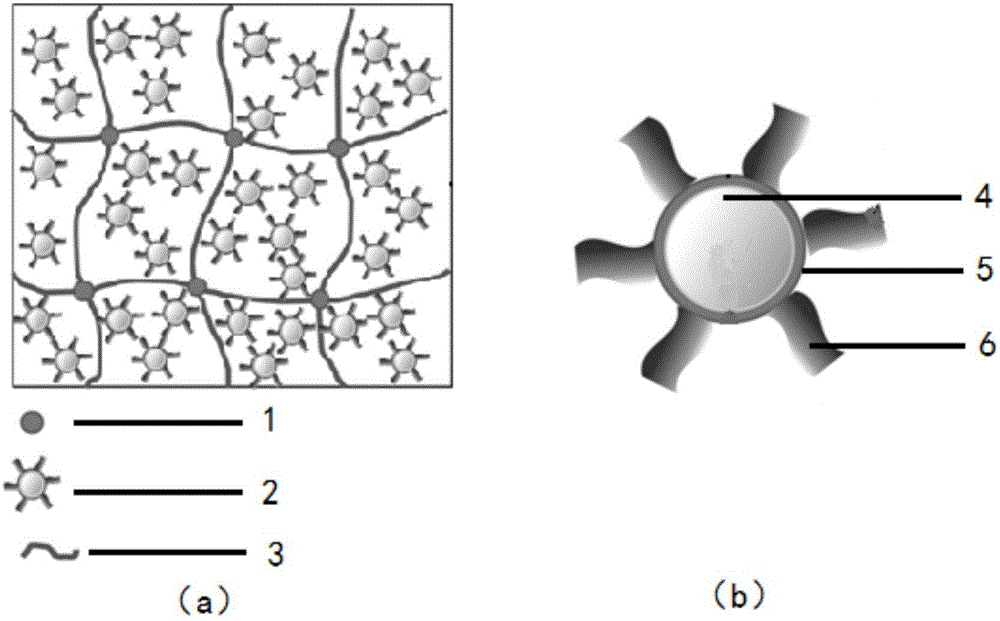

Multi-layer core shell structure graphene based dielectric elastomer composite material and preparation method

A multi-layer core-shell structure and alkenyl dielectric technology, which is applied in the field of dielectric elastomer preparation, can solve the problems of increased dielectric loss, reduced electrical breakdown strength, and large amount of added particles, so as to improve the electrical deformation, Effect of reducing dielectric loss and increasing dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 20 mg of dopamine to 100 ml of water, and add tris (Tris) to adjust the pH of the deionized water to 8.5 to obtain a dopamine solution;

[0036] (2) Add 1g of barium titanate particles with a particle size of 30nm to the dopamine aqueous solution, and mechanically stir for 18 hours at 25°C. After the reaction is completed, dilute to neutral with deionized water, filter with suction, and dry in vacuum to obtain the polydopamine package. Barium titanate coated ceramic particles;

[0037] (3) Ultrasonic dispersion of 0.5g graphene oxide in 1000ml deionized water, 800W ultrasonic dispersion for 6h, to obtain an aqueous solution of graphene oxide;

[0038] (4) Add 1 g of polydopamine-coated barium titanate ceramic particles to graphene oxide aqueous solution, mechanically stir at 25°C for 16 hours, dilute with deionized water until neutral, vacuum filter, and vacuum dry to obtain graphene oxide Modified polydopamine coated high dielectric ceramic filler;

[0039] (...

Embodiment 2

[0046] The preparation method is the same as in Example 1, except that the amount of dopamine added in step (1) is 33 mg, and the amount of graphene-based ceramic particles in step (6) is 4.5 g. The test results are shown in Table 1.

Embodiment 3

[0048] The preparation method is the same as in Example 1, except that the consumption of dicumyl peroxide in the step (6) is 2g. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com