Antimicrobial polyurethane composite and preparation method and application thereof

A composite material and polyurethane technology, applied in the field of composite materials, can solve the problems of spreading bacteria, cracks on the surface, poor flexibility, etc., to avoid breeding and spreading, improve antibacterial properties, and ensure non-toxic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

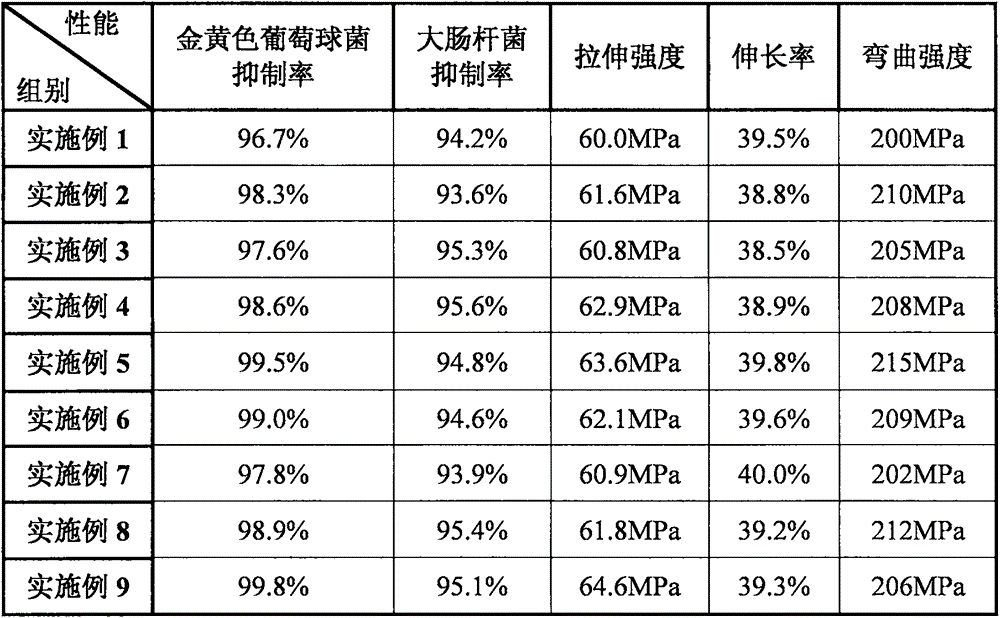

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of above-mentioned antibacterial polyurethane composite material on the other hand; It is characterized in that, concrete steps are as follows:

[0032] Step 1, preparation of epoxidized polybutadiene prepolymer: first weigh epoxidized polybutadiene, copper acetylacetonate, isocyanate and ethyl acetate in proportion; then add copper acetylacetonate to ethyl acetate Mix until completely dissolved, then add the mixed solution into epoxidized polybutadiene, stir evenly and heat it in a water bath at 65-75°C to obtain a mixed solution; then add isocyanate into the mixed solution, at 65 Stir at ~75°C for 30-40min, with a stirring speed of 100-200r / min, take it out and cool it down to obtain an epoxidized polybutadiene prepolymer;

[0033] Step 2, preparation of modified polyurethane: adding the epoxidized polybutadiene prepolymer into the polyol in proportion, and obtaining the modified polyurethane after mixin...

Embodiment 1

[0037] An antibacterial polyurethane composite material, the polyurethane composite material is composed of the following raw materials: 50 parts by weight of modified polyurethane, 10 parts by weight of composite antibacterial agent, and 10 parts by weight of fiber reinforcement 10 parts by weight of ceramic filler, 10 parts by weight of curing agent, 2 parts by weight of diluent, 5 parts by weight of silane coupling agent, and 5 parts by weight of surfactant 3 parts; the composite antibacterial agent is composed of 60wt% silver-loaded nano-titanium dioxide and 40wt% chitosan; the particle size of the silver-loaded nano-titanium dioxide is 20-180nm, wherein the silver-loaded nano-titanium dioxide The particle size distribution is: 20~50nm accounts for 10~20wt%, 50~80nm accounts for 30~40wt%, 80~120nm accounts for 30~40wt%, 120~180nm accounts for 10~20wt%; The particle diameter of described chitosan 200nm to 300nm.

Embodiment 2

[0039] An antibacterial polyurethane composite material, the polyurethane composite material is composed of the following raw materials: 70 parts by weight of modified polyurethane, 5 parts by weight of composite antibacterial agent, and 5 parts by weight of fiber reinforcement , the parts by weight of the ceramic filler are 5 parts, the parts by weight of the curing agent are 10 parts, the parts by weight of the diluent are 5 parts, the parts by weight of the silane coupling agent are 5 parts, the parts by weight of the surfactant It is composed of 5 parts; the composite antibacterial agent is composed of 55wt% silver-loaded nano-titanium dioxide and 45wt% chitosan; the particle size of the silver-loaded nano-titanium dioxide is 20-180nm, distributed in chitosan capsules , the particle diameter of the chitosan capsule is 0.25-0.76 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com