Novel composite protective agent for freeze-dried preparation of staphylococcus aureus

A staphylococcus and aureus technology, applied in the field of microorganisms, can solve the problem of unsatisfactory protective effect of protective agents, achieve the effect of inhibiting oxidation and free radical formation, stable structure, stable structure and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition of the novel compound protective agent for freeze-drying preparation of Staphylococcus aureus of this embodiment is: trehalose 2g, sodium glutamate 12g, L-cysteine hydrochloride 0.5g, bovine serum albumin 0.25g, distilled water 100ml.

[0021] Its preparation method:

[0022] 1) Add 2g of trehalose and 12g of sodium glutamate in distilled water according to the amount, sterilize at 113°C for 15min, and cool to room temperature;

[0023] 2) Dissolve 0.5g of L-cysteine hydrochloride and 0.25g of bovine serum albumin in distilled water according to the amount, and then filter and sterilize with a 0.22μm filter membrane;

[0024] 3) Mix the solutions prepared in steps 1) and 2), and adjust the total mass volume percentage of water to 100%, to obtain the Staphylococcus aureus composite lyoprotectant.

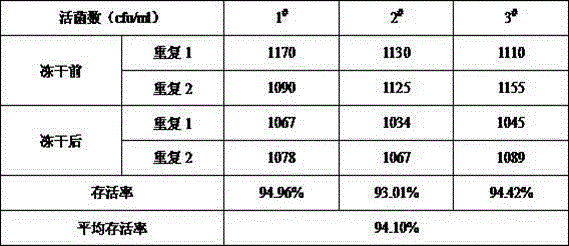

[0025] After activated culture, centrifugation and washing of Staphylococcus aureus, the sludge was collected, mixed with a protective agent before freez...

Embodiment 2

[0028] The composition of the novel compound protective agent for freeze-drying preparation of Staphylococcus aureus in this example is: trehalose 4g, sodium glutamate 12g, L-cysteine hydrochloride 1g, bovine serum albumin 0.75g, distilled water 100ml .

[0029] Its preparation method:

[0030] 1) Add 4g of trehalose and 12g of sodium glutamate in distilled water according to the amount, sterilize at 113°C for 15min, and cool to room temperature;

[0031] 2) Dissolve 1g of L-cysteine hydrochloride and 0.75g of bovine serum albumin in distilled water according to the amount, and then filter and sterilize with a 0.22μm filter membrane;

[0032] 3) The solutions prepared in steps 1) and 2) were mixed, and the total mass volume percentage of water was adjusted to 100% to obtain a Staphylococcus aureus lyoprotectant.

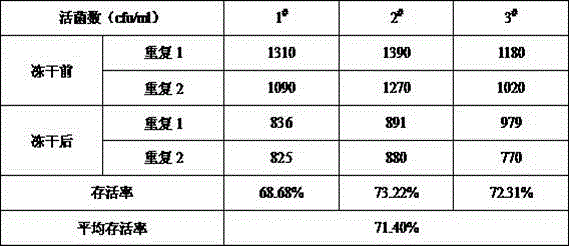

[0033] Staphylococcus aureus was activated, cultured, centrifuged, and cleaned, and the sludge was collected, mixed with a protective agent before freeze-dryin...

Embodiment 3

[0036] The composition of the novel composite protective agent for freeze-drying preparation of Staphylococcus aureus in this example is: trehalose 6g, sodium glutamate 18g, L-cysteine hydrochloride 1g, bovine serum albumin 0.25g, distilled water 100ml .

[0037] Its preparation method:

[0038] 1) Add 6g of trehalose and 18g of sodium glutamate in distilled water according to the amount, sterilize at 113°C for 15min, and cool to room temperature;

[0039] 2) Dissolve 1g of L-cysteine hydrochloride and 0.25g of bovine serum albumin in distilled water according to the amount, and then filter and sterilize with a 0.22μm filter membrane;

[0040] 3) The solutions prepared in steps 1) and 2) were mixed, and the total mass volume percentage of water was adjusted to 100% to obtain a Staphylococcus aureus lyoprotectant.

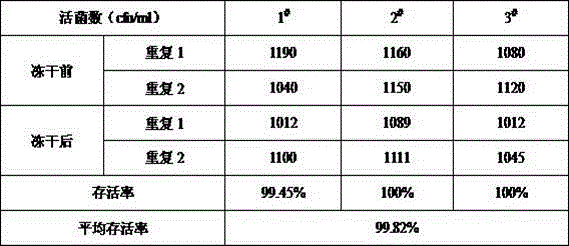

[0041] Staphylococcus aureus was activated, cultured, centrifuged, and cleaned, and the sludge was collected, mixed with a protective agent before freeze-dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com