A preparing method of a glass ceramic type solid electrolyte

A technology of solid electrolyte and glass ceramics, which is applied in the preparation of Li1+xAlxTi2-x3 glass ceramic solid electrolyte and the field of solid electrolyte preparation, which can solve the problems of low ion conductivity, complicated preparation process, and long sintering time, and achieve sintering The time is short, the preparation method is simple and easy, and the effect of improving the synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

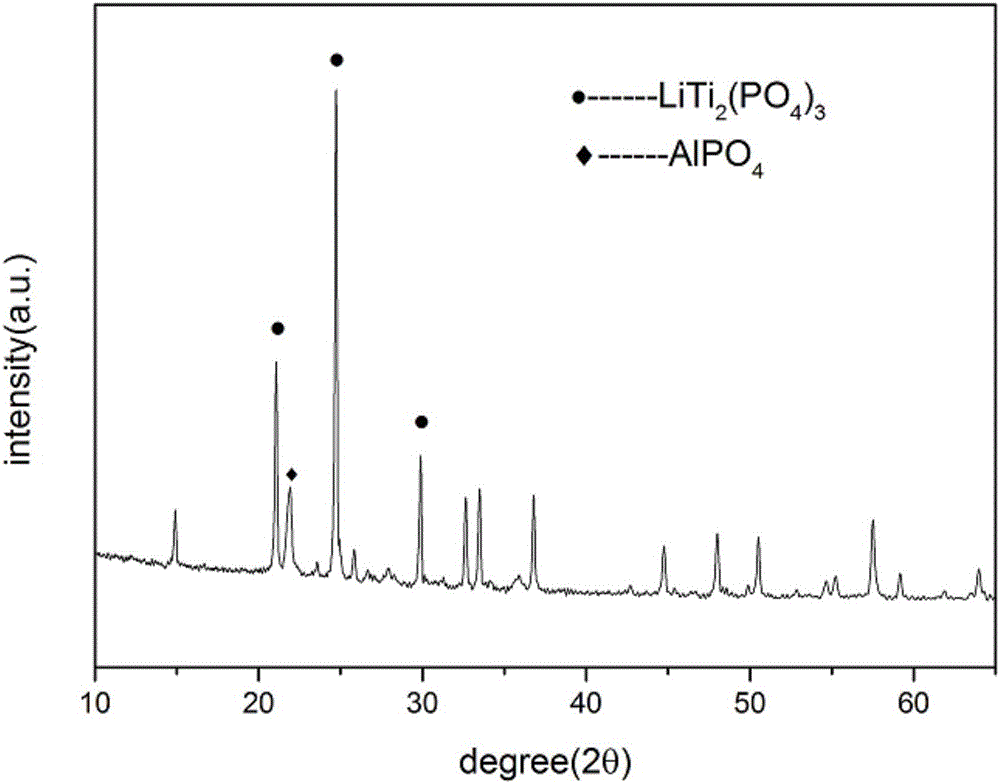

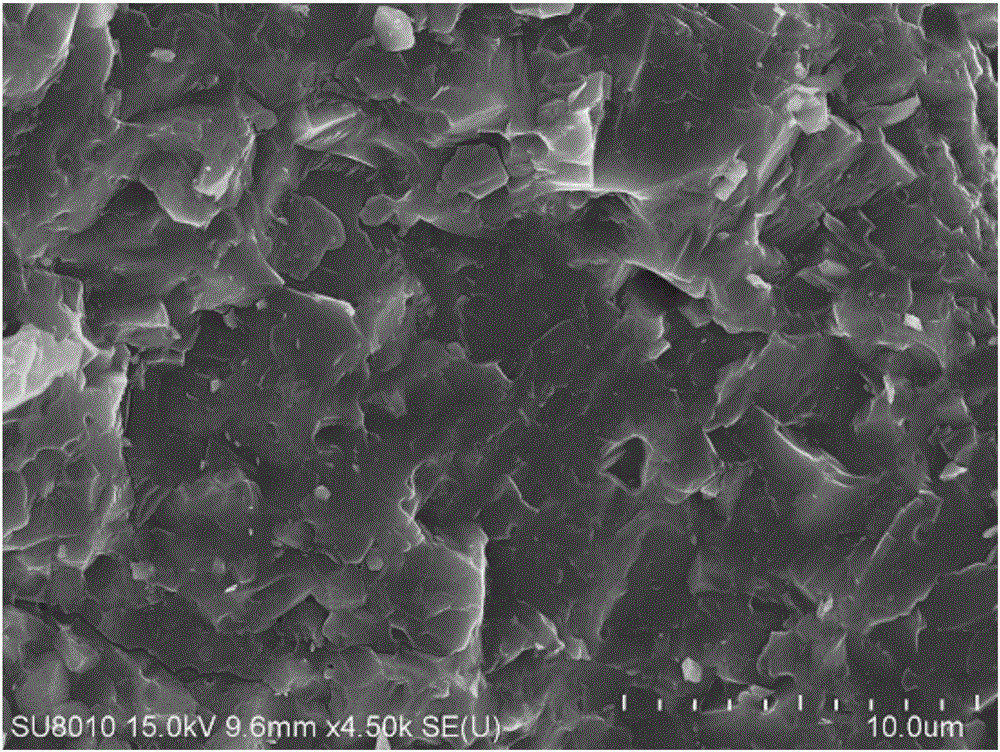

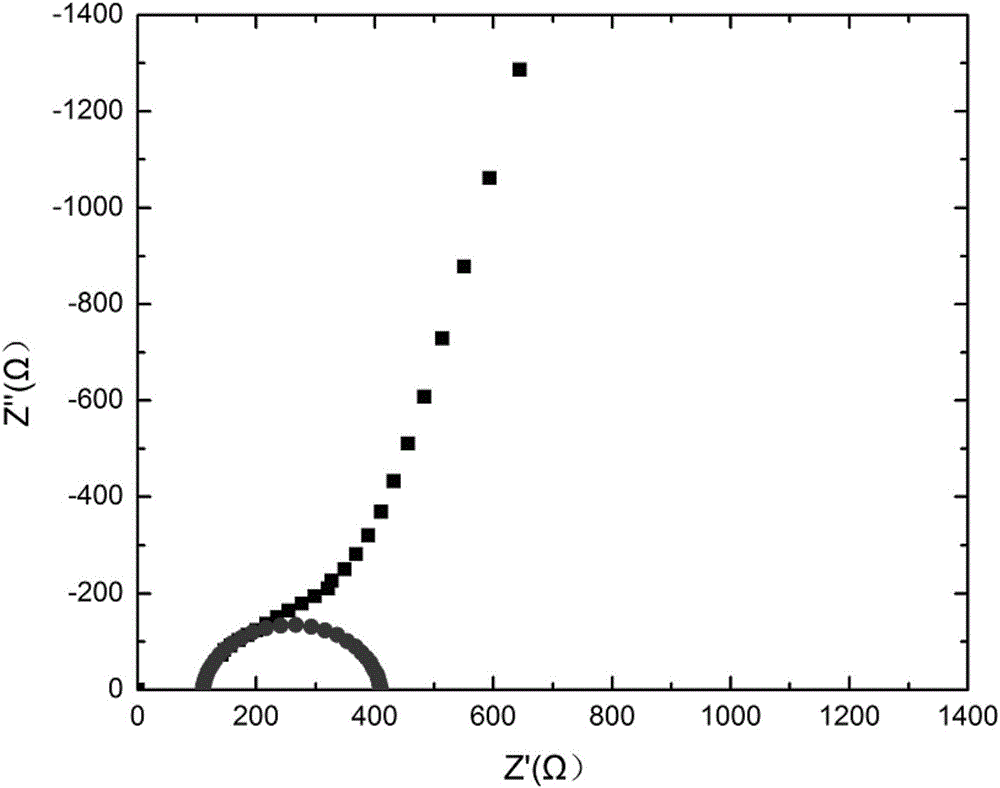

[0025] Weigh 6.2wt% Li 2 CO 3 , 4.9 wt% Al 2 o 3 , 19.9 wt% TiO 2 and 69.0wt% (NH 4 ) 2 HPO 4 The powder is manually ground for 5 minutes, and then the planetary ball mill is used for 0.5 hours. The ball milling medium is zirconia spheres with a diameter of 1 mm and 4 mm. The solvent is absolute ethanol, and the mass ratio of solvent to raw material is 1:1. After ball milling, put it into a vacuum drying oven and dry at 100°C for 10 hours. Put the dried powder into an agate mortar and grind it manually for 30 minutes. The uniformly mixed raw materials are put into an alumina crucible with a purity of 99% for high-temperature melting. First keep the temperature at 700°C for 1 hour, then raise the temperature to 1550°C for 2 hours, and obtain the required glass slag after water quenching. Grind the glass slag manually for 5 minutes, and then use dry ball milling to obtain glass powder. The ball milling medium is 1mm and There are two kinds of 4mm zirconia spheres, the b...

Embodiment 2

[0027] Weigh 6.2wt% Li 2 CO 3 , 4.9 wt% Al 2 o 3 , 20.3wt% TiO 2 and 68.6wt% (NH 4 ) 2 HPO 4 Powder, first manually grind for 5 minutes, and then use planetary ball mill wet ball for 1 hour, the ball milling medium is two kinds of zirconia spheres with a diameter of 1mm and 4mm, the solvent is absolute ethanol, the mass ratio of solvent to raw material is 1:1, ball milling Then put it into a vacuum drying oven and dry it at 100°C for 10h. Put the dried powder into an agate mortar and grind it manually for 30 minutes. The uniformly mixed raw materials are put into an alumina crucible with a purity of 99% for high-temperature melting. First keep the temperature at 700°C for 2 hours, then raise the temperature to 1550°C for 2 hours, and obtain the required glass slag after water quenching. Grind the glass slag manually for 5 minutes, and then use dry ball milling to obtain glass powder. The ball milling time is 10 hours. The ball milling medium is 1mm and 4mm zirconia sp...

Embodiment 3

[0029] Weigh 5.7wt% Li 2 CO 3 , 4.5 wt% Al 2 o 3 , 20.1wt% TiO 2 and 69.7wt% (NH 4 ) 2 HPO 4 The powder is manually ground for 5 minutes, and then the planetary ball mill is used for 0.5 hours. The ball milling medium is zirconia spheres with a diameter of 1 mm and 4 mm. The solvent is absolute ethanol, and the mass ratio of solvent to raw material is 1:1. After ball milling, put it into a vacuum drying oven and dry at 100°C for 10 hours. Put the dried powder into an agate mortar and grind it manually for 30 minutes. The uniformly mixed raw materials are put into an alumina crucible with a purity of 99% for high-temperature melting. First keep the temperature at 700°C for 1 hour, then raise the temperature to 1550°C for 2 hours, and obtain the required glass slag after water quenching. Grind the glass slag manually for 5 minutes, and then use dry ball milling to obtain glass powder. The ball milling medium is 1mm and There are two kinds of 4mm zirconia spheres, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com