Method for preparing rubber powder/natural rubber liquid-phase mixed compound rubber

A technology of natural rubber and liquid phase mixing, which is applied in the field of preparation of natural rubber composite rubber, can solve the problems of product physical and mechanical properties and processing performance reduction, uneven dispersion, and poor compatibility of rubber powder blending, etc., to improve the physical Mechanical properties, good dispersibility, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

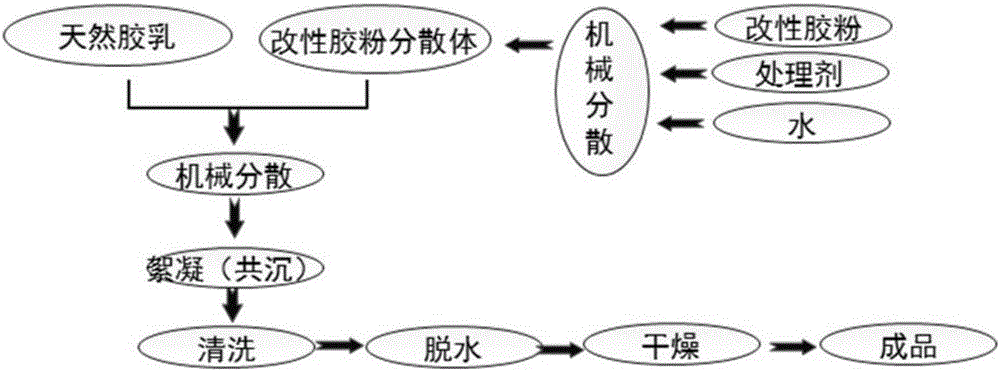

Method used

Image

Examples

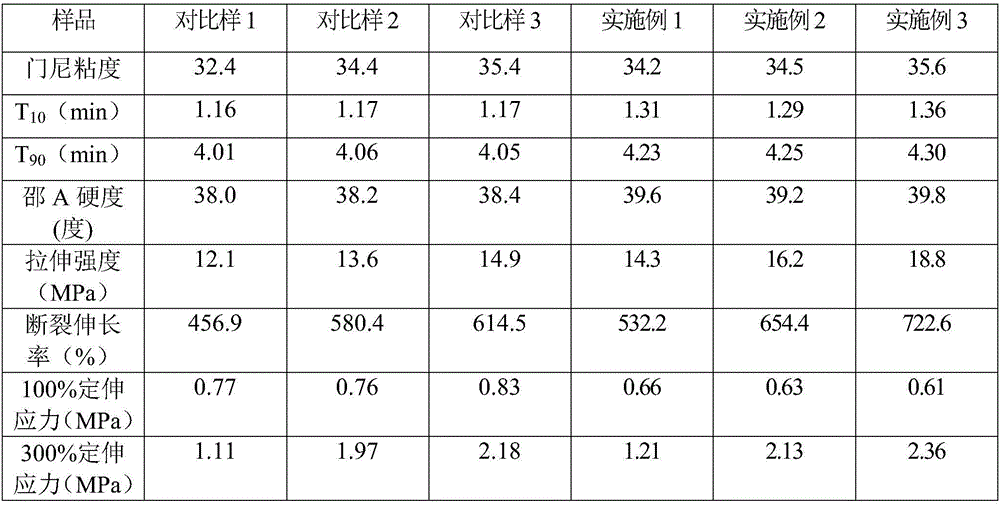

Embodiment 1

[0040] This embodiment provides a method for preparing rubber powder / natural rubber liquid phase mixing composite rubber, comprising the following steps:

[0041] (1) 80 mesh 10 parts by weight of rubber powder, 88 parts by weight of water, 1.5 parts by weight of polyvinyl alcohol and 0.5 parts by weight of N~phenyl~β~naphthylamine, at room temperature, under the condition of 500 rpm Mix and stir for 30 minutes to obtain a stable rubber powder dispersion;

[0042] (2) the latex of the solid content 40% of 100 parts by weight, the water of 99 parts by weight, the microbial protease of 0.5 parts by weight and the stabilizer of 0.5 parts by weight were mixed and stirred for 10 minutes at room temperature, under the condition of 50 rev / min, prepared pretreated latex;

[0043] (3) Add the rubber powder dispersion and pretreated latex into the mixer in a ratio of 2:5, mix for 20 minutes at 1000 rpm and stir, then add 2 parts by weight of 2% acetic acid and stir until the mixed gel ...

Embodiment 2

[0046] (1) 120 orders of 10 parts by weight of rubber powder, 88 parts by weight of water, 1.5 parts by weight of polyvinyl alcohol and 0.5 parts by weight of antioxidant 1010 were mixed and stirred for 40 minutes at room temperature and at 500 rpm, Obtain a stable rubber powder dispersion;

[0047] (2) the latex of 40% solid content of 100 weight parts, the water of 99 weight parts, the microbial protease of 0.5 weight part and the stabilizing agent of 0.5 weight part were mixed and stirred for 20 minutes under the conditions of room temperature and 50 rev / min, and prepared pretreated latex;

[0048] (3) Add the rubber powder dispersion and the pretreated latex into the mixer according to the ratio of 2:5, mix and stir for 20 minutes under the condition of 1000 rpm, add 0.5 parts by weight of 2% acetic acid and stir until the mixed gel is fully solidified;

[0049] (4) washing the solidified mixed rubber, extruding to remove water, and drying to obtain rubber powder / natural ...

Embodiment 3

[0051] This embodiment provides a method for preparing rubber powder / natural rubber liquid phase mixing composite rubber, comprising the following steps:

[0052](1) 200 mesh 10 parts by weight of rubber powder, 88 parts by weight of water, 1.5 parts by weight of polyvinyl alcohol and 0.5 parts by weight of N~phenyl~β~naphthylamine, at room temperature, under the condition of 500 rpm Mix and stir for 30 minutes to obtain a stable rubber powder dispersion;

[0053] (2) the latex of the solid content 40% of 100 parts by weight, the water of 99 parts by weight, the microbial protease of 0.5 parts by weight and the stabilizer of 0.5 parts by weight were mixed and stirred for 10 minutes at room temperature, under the condition of 50 rev / min, prepared pretreated latex;

[0054] (3) Add the rubber powder dispersion and pretreated latex into the mixer in a ratio of 3:5, mix for 20 minutes at 1000 rpm and stir, then add 2 parts by weight of 2% acetic acid and stir until the mixed gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com