Nano-zirconium phosphate with functions of catalytic char formation and free radical quenching and its preparation method and application

A nano-zirconium phosphate and functional nano-technology, applied in the field of halogen-free flame retardants, can solve the problems of easy agglomeration and no way to solve the easy agglomeration of zirconium phosphate, and achieve easy agglomeration, excellent free radical quenching function, and air tightness and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

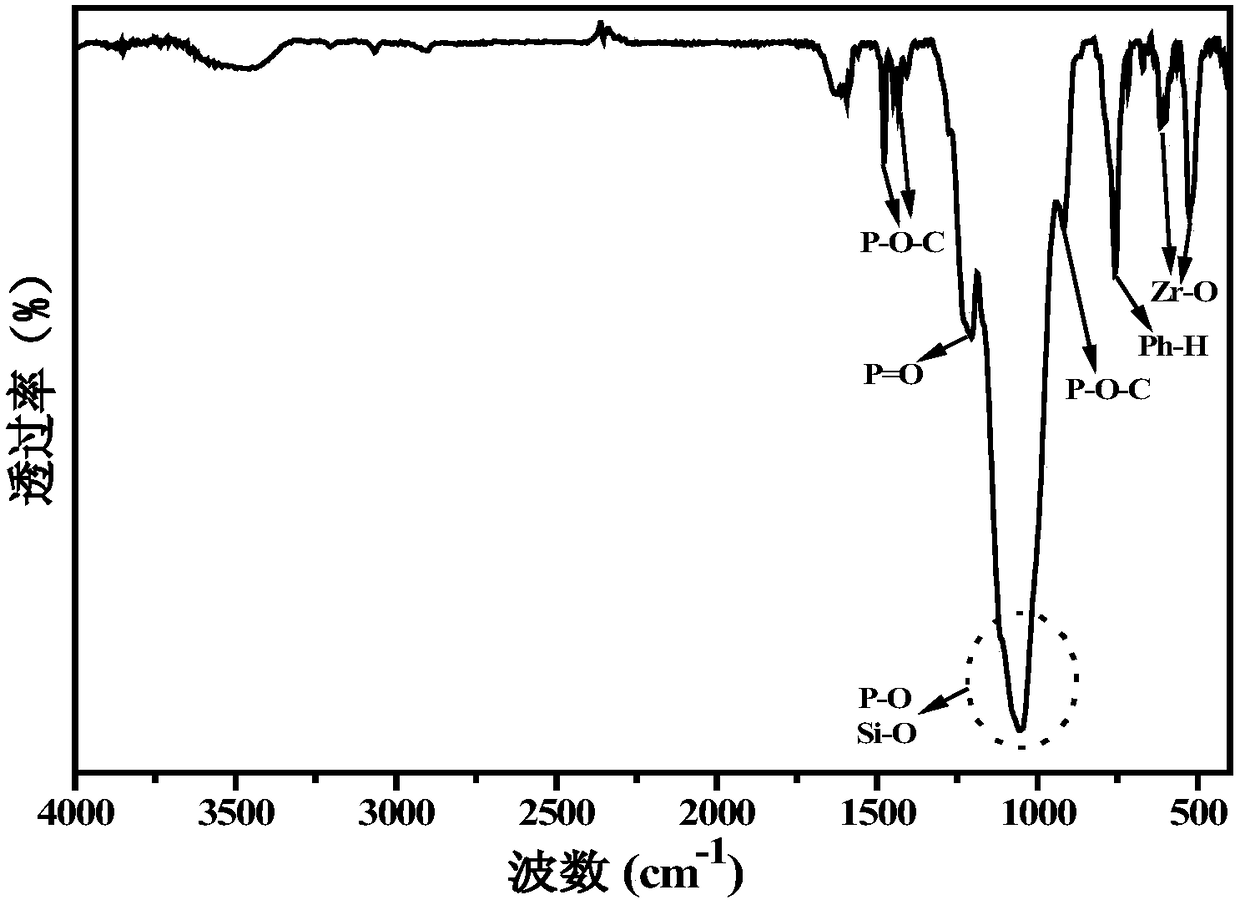

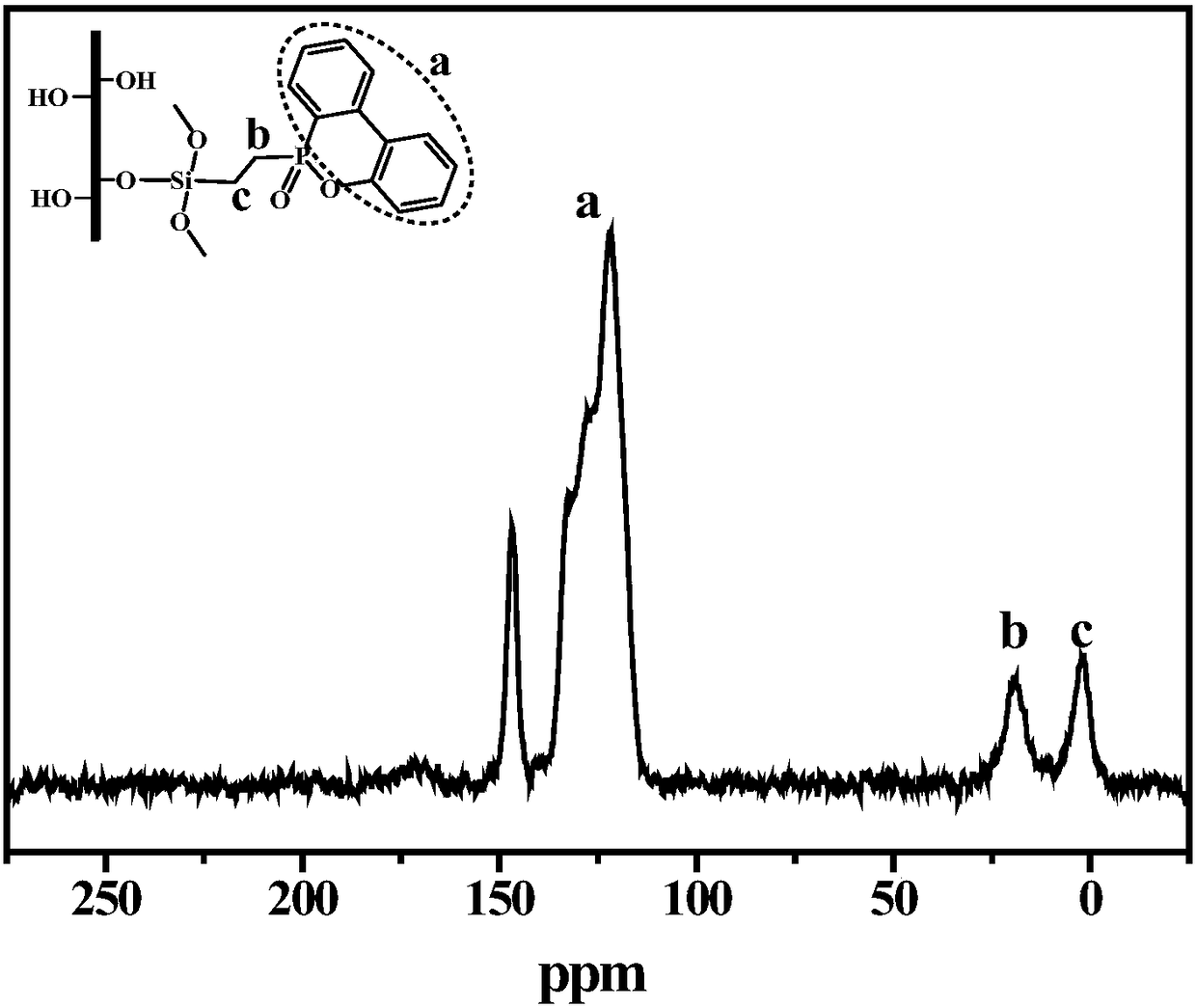

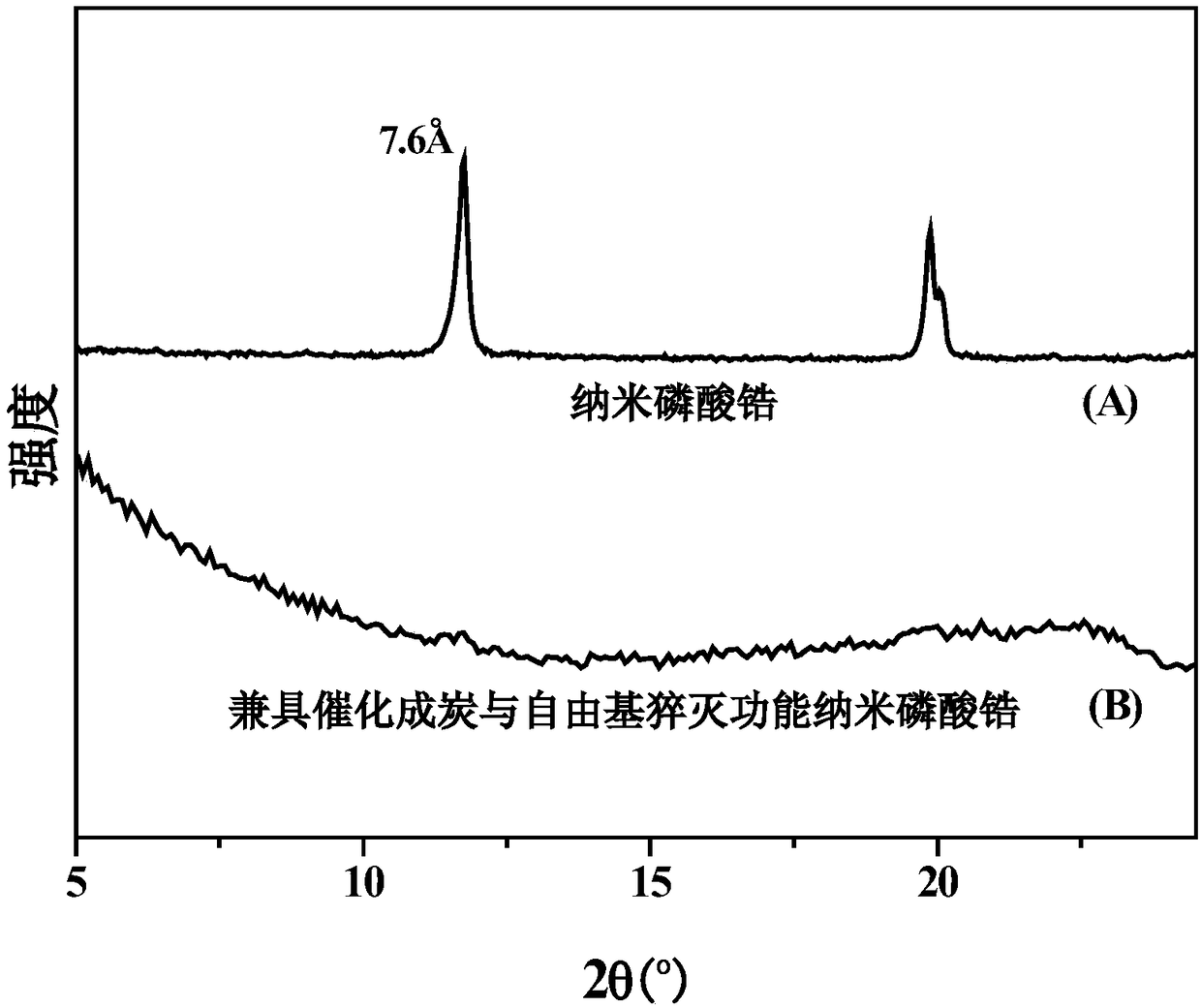

[0050] 1) Intercalation and exfoliation of nano-zirconium phosphate: Add 400 mL of deionized water and 4.00 g (0.014 mol) of nano-zirconium phosphate (sheet diameter is about 500 nm) into a 1L four-neck flask at 0-5 °C, and stir ultrasonically 30min, zirconium phosphate is fully dispersed; 14.68g (0.014mol) tetrabutylammonium hydroxide (aqueous solution, mass concentration is 25%) is mixed with 130.40g deionized water and is mixed with the tetrabutylammonium hydroxide aqueous solution of 0.1mol / L, in Under the condition of ultrasonic stirring, add dropwise into the reaction kettle within 1 hour, continue ultrasonic stirring for 1 hour after dropping, then stop the ultrasonic wave, and continue stirring for 5 hours; Add dropwise into the reaction kettle, and continue ultrasonic stirring for 1 h; after the reaction, the mixed solution is centrifuged, the precipitate is washed three times with dioxane, and then dispersed in 400 mL of dioxane by ultrasonic stirring to form a suspen...

Embodiment 2

[0057] The difference between this example and Example 1 is that in step 1), zirconium phosphate with a sheet diameter of 1000nm is used instead, the ultrasonic stirring time is extended to 1.5h after the silane coupling agent is added dropwise, and the continuous stirring time is extended after stopping the ultrasonic to 6h. The flame retardant performance test and thermogravimetric analysis results are shown in Table 1.

Embodiment 3

[0059] The difference between this embodiment and Example 1 is that in step 1), zirconium phosphate with a sheet diameter of 1500nm is used instead, the ultrasonic stirring time is extended to 2h after the silane coupling agent is added dropwise, and the continuous stirring time is extended to 2h after stopping the ultrasonic. 7h. The flame retardant performance test and thermogravimetric analysis results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com