Preparation method for carbon nanotube super-hydrophobic coating

A technology of super-hydrophobic coating and carbon nanotubes, which is applied in coatings, conductive coatings, etc., can solve the problems of difficult large-scale preparation, cumbersome preparation process, and harsh conditions, so as to avoid agglomeration, simple process, and keep the surface dry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

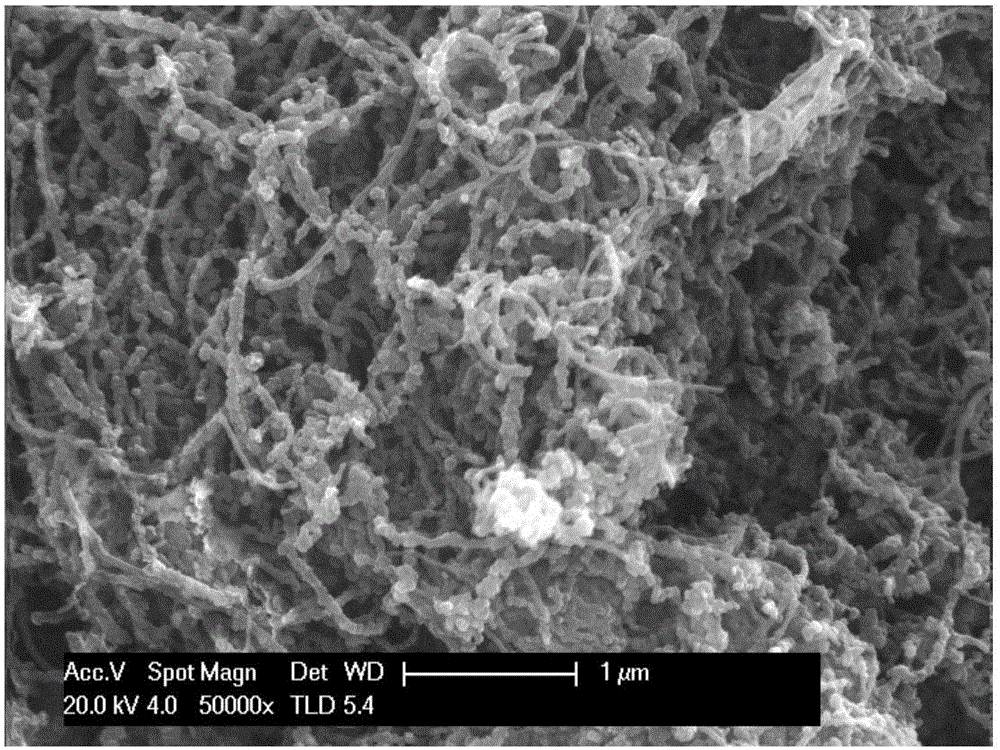

[0020] Example 1: Preparation of carbon nanotube superhydrophobic coating by glass substrate substrate spraying method

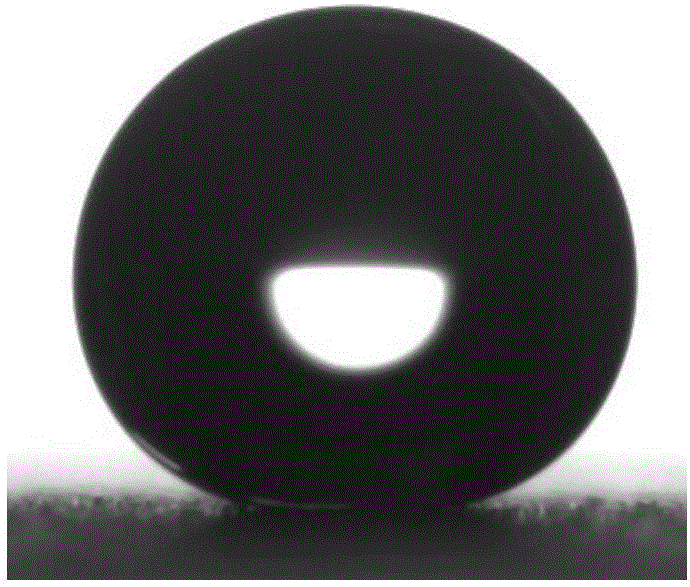

[0021] Add 80 parts of absolute ethanol, 1 part of ammonia water, 4 parts of deionized water, and 0.8 parts of multi-walled carbon nanotubes into the beaker in a water bath at 35°C. The inner diameter of the nanotubes is 40-50 nm, the length is 10-30 μm, and the hydroxyl content is 5.58%, ultrasonically disperse for 0.5h, add 0.5 parts of tetraethyl orthosilicate dropwise to the solution, react for 1h; finally add 1 part of fluorosilane dropwise into the solution, stir for 24h to obtain a super-hydrophobic coating solution, and The solution was sprayed on the cleaned glass substrate and dried at room temperature to obtain a superhydrophobic coating of carbon nanotubes. The surface morphology was as follows: figure 1 As shown, the static contact angle of a water droplet on it is as figure 2 As shown, the contact angle is 160.3°.

example 2

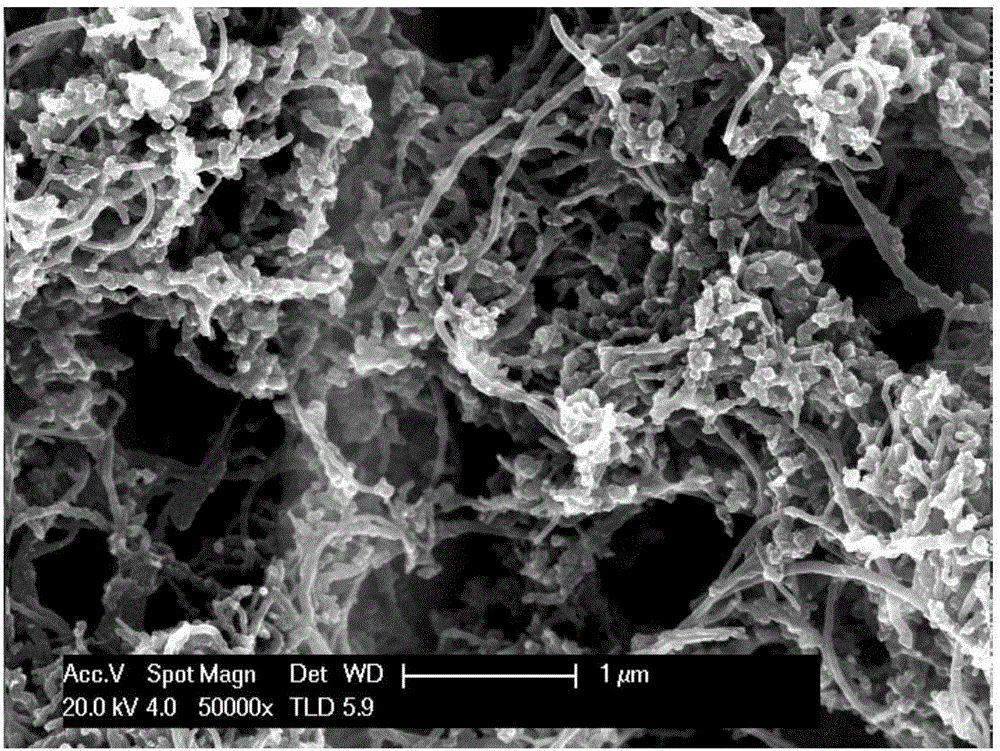

[0022] Example 2: Preparation of carbon nanotube superhydrophobic coating by spin coating on copper substrate

[0023] Add 130 parts of absolute ethanol, 2.5 parts of ammonia water, 6 parts of deionized water, and 1 part of multi-walled carbon nanotubes into a beaker under the condition of a water bath at 30°C. The inner diameter of the nanotubes is 2-5 nm, the length is 10-30 μm, and the hydroxyl content is 5%, ultrasonically disperse for 1 hour, add 0.8 parts of tetraethyl orthosilicate dropwise to the solution, and react for 1.2 hours; finally, add 1 part of fluorosilane dropwise to the solution, and stir for 36 hours to obtain a superhydrophobic coating solution. The solution was spin-coated on the cleaned copper substrate, and dried at room temperature to obtain a superhydrophobic coating of carbon nanotubes. The surface morphology was as follows: image 3 As shown, condensation condensation self-bounces as Figure 4 As shown, although the carbon nanotubes can be directl...

example 3

[0024] Example 3: Preparation of carbon nanotube superhydrophobic coating by dipping micro-array silicon substrate

[0025] Add 160 parts of absolute ethanol, 4 parts of ammonia water, 7 parts of deionized water, and 1.5 parts of multi-walled carbon nanotubes into the beaker under the condition of a water bath at 45°C. The inner diameter of the nanotubes is 2-5 nm, the length is 1-3 μm, and the hydroxyl content is 8%, ultrasonically disperse for 1 hour, add 1.2 parts of tetraethyl orthosilicate dropwise to the solution, and react for 1.5 hours; finally, add 1.5 parts of fluorosilane dropwise to the solution, and stir for 58 hours to obtain a superhydrophobic coating solution. Dip the cleaned micron silicon column substrate into the solution, take it out and blow dry, repeat 3 to 5 times, and dry at room temperature to obtain a carbon nanotube superhydrophobic coating. The static contact of water droplets on it is as follows: Figure 5 As shown, the contact angle is 159.9°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com