Mineralization synthesis method for nano sulfate

A technology of nano-calcium sulfate and sulfate, applied in chemical instruments and methods, calcium/strontium/barium sulfate, nanotechnology, etc., can solve problems such as human health threats and environmental pollution, and achieve high practical value, environmental friendliness, fast breeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

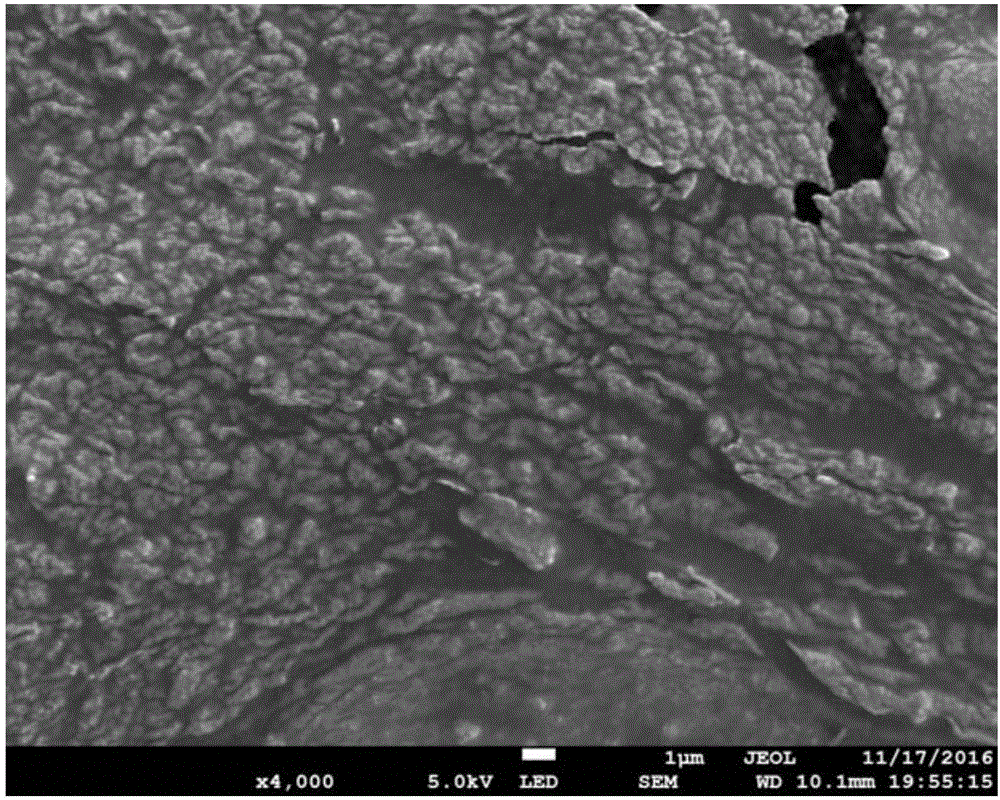

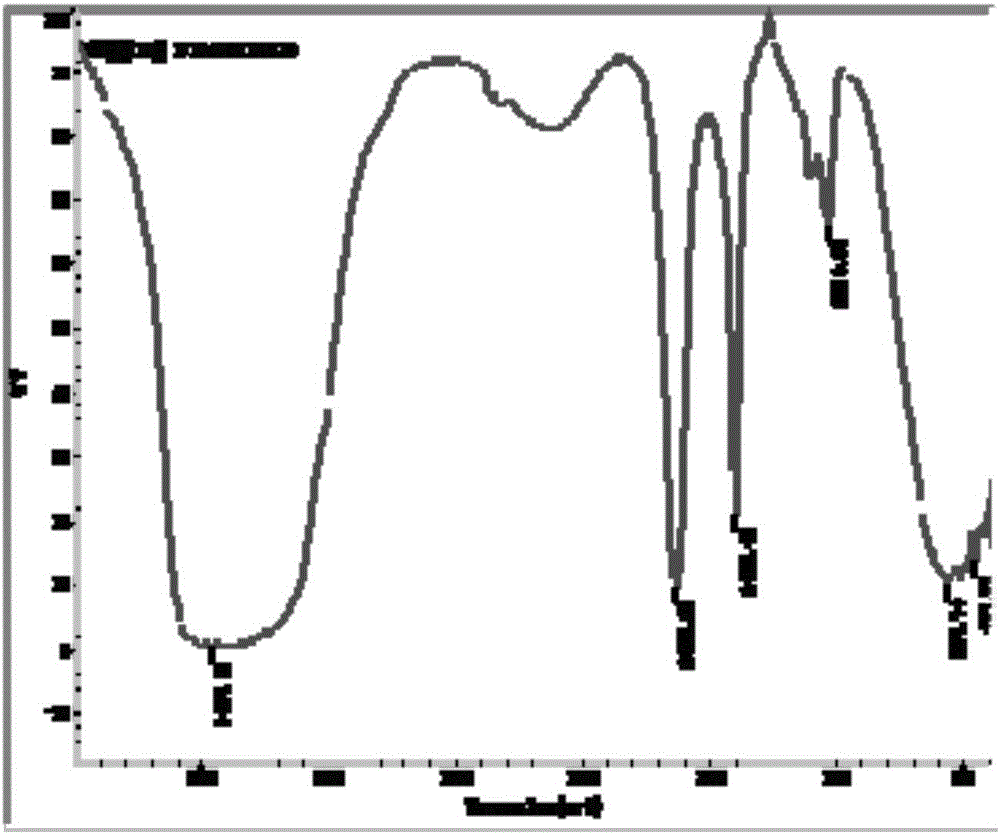

[0030] Take 10 grams of sodium thiosulfate, 1.2 grams of disodium hydrogen phosphate, 1.8 grams of potassium dihydrogen phosphate, 0.1 grams of magnesium sulfate heptahydrate, 0.1 grams of ammonium sulfate, 0.02 grams of ferric chloride, and 0.02 grams of manganese sulfate in 1000 ml of deionized Make a solution in water; divide the solution evenly into 5 Erlenmeyer flasks and seal them; put the Erlenmeyer flasks into a sterilizer, sterilize at 121°C for 100 minutes, and cool to room temperature. For aseptic operation, insert 5 ml of the third-generation Thiobacillus thioexhausen into each bottle, culture it in a constant temperature shaker at 170rpm and 30°C for 6-8 days, and take it out; inject 30ppm of hydrogen sulfide gas into each Erlenmeyer flask for half the time. Hours, let stand for 12 to 24 hours; filter to obtain the filtrate. Take 10 grams of CaCl 2 2H 2 O, join in the filtrate to react, produce a large number of white precipitates, filter and dry to get nanomete...

Embodiment 2

[0032] Take 8 grams of sodium thiosulfate, 1.1 grams of disodium hydrogen phosphate, 1.5 grams of potassium dihydrogen phosphate, 0.2 grams of magnesium sulfate heptahydrate, 0.05 grams of ammonium sulfate, 0.01 grams of ferric chloride, and 0.01 grams of manganese sulfate in 1000 ml of deionized In water, make a solution; divide the solution evenly into 5 Erlenmeyer flasks and seal them; put the Erlenmeyer flasks into a sterilizer, sterilize at 121°C for 100 minutes, and cool to room temperature. For aseptic operation, insert 5 ml of the third-generation Thiobacillus thioexhausen into each bottle, culture it in a constant temperature shaker at 170rpm and 30°C for 6-8 days, and take it out; inject 30ppm of hydrogen sulfide gas into each Erlenmeyer flask for half the time. Hours, let stand for 12 to 24 hours; filter to obtain the filtrate. Take 10 grams of CaCl 2 2H 2 O, join in the filtrate to react, produce a large number of white precipitates, filter and dry to get nanomet...

Embodiment 3

[0034] Take 11 grams of sodium thiosulfate, 1.3 grams of disodium hydrogen phosphate, 2.0 grams of potassium dihydrogen phosphate, 0.3 grams of magnesium sulfate heptahydrate, 0.2 grams of ammonium sulfate, 0.03 grams of ferric chloride, and 0.03 grams of manganese sulfate in 1000 ml of deionized In water, make a solution; divide the solution evenly into 5 Erlenmeyer flasks and seal them; put the Erlenmeyer flasks into a sterilizer, sterilize at 121°C for 100 minutes, and cool to room temperature. For aseptic operation, insert 5 ml of the third-generation Thiobacillus thioexhausen into each bottle, culture it in a constant temperature shaker at 170rpm and 30°C for 6-8 days, and take it out; inject 30ppm of hydrogen sulfide gas into each Erlenmeyer flask for half the time. Hours, let stand for 12 to 24 hours; filter to obtain the filtrate. Take 10 grams of CaCl 2 2H 2 O, join in the filtrate to react, produce a large number of white precipitates, filter and dry to get nanomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com