Total heat exchange membrane and preparation method thereof

A technology of total heat exchange membrane and total heat exchange core, which is applied in the field of polymer composite materials, can solve the problems of substrate defects, decline in mechanical properties, and influence of water molecules permeating the membrane, so as to achieve high mechanical strength and improve display efficiency. The effect of heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The total heat exchange membrane of Example 1 was prepared by the following steps, which included:

[0052] (1) Adopting the viscose fiber containing 5wt.% graphene as raw material, processed into a grammage of 35g / m 2 , non-woven fabric with a thickness of 260 μm;

[0053] (2) Take 10g of polyvinyl alcohol, add 100ml of water and keep at 90°C for 2 hours to dissolve; then add 0.05g of calcium chloride, 0.05g of calcium hydroxide and 0.1g of polyethylene glycol-2000, keep warm at 70°C and continue Stir for 2 hours until the additives are evenly dispersed, then let stand for 12 hours for defoaming;

[0054] (3) Apply the mixture obtained in step (2) evenly on the surface of the non-woven fabric, and keep it dry for 8 hours in an air-blast drying oven at 80° C. to obtain a total heat exchange membrane.

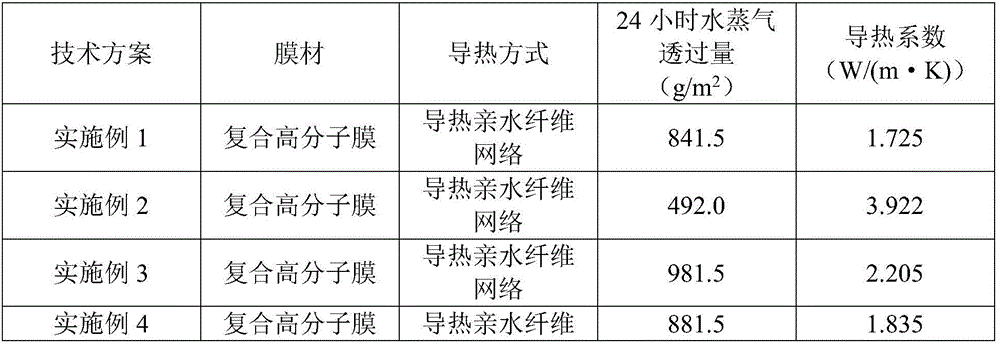

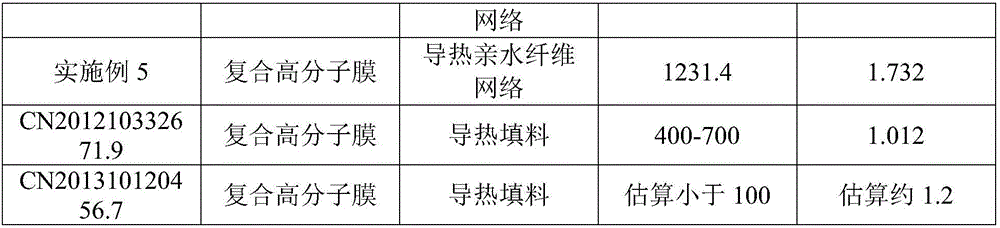

[0055] The above-mentioned total heat exchange membrane is tested for water vapor transmission rate, and the test method is based on the national standard GB1037-88. U...

Embodiment 2

[0058] (1) Adopting the hydrophilic acrylic fiber containing 20wt.% graphite as raw material, processed into a gram weight of 50g / m 2 , non-woven fabric with a thickness of 350 μm;

[0059] (2) Take 20g of polyvinylpyrrolidone, add 150ml of N-methylpyrrolidone and keep it sealed at 60°C for 4 hours to dissolve; then add 0.2g of magnesium chloride, 0.1g of aluminum hydroxide and 0.1g of polyethylene glycol-2000, and keep warm for 40 Continue to stir for 8 hours at ℃ until the additives are evenly dispersed; then stand for 12 hours for defoaming;

[0060] (3) Apply the mixture obtained in step (2) evenly on the surface of the non-woven fabric, and keep it dry in a blast drying oven at 60° C. for 12 hours; a total heat exchange membrane is obtained.

[0061] The water vapor transmission rate test was carried out on the above-mentioned total heat exchange membrane, the conditions were the same as in Example 1, and the water vapor transmission rate obtained in 24 hours was 492.0g / ...

Embodiment 3

[0064] (1) Adopting the viscose fiber containing 20wt.% graphite as raw material, processed into a gram weight of 45g / m 2 , non-woven fabric with a thickness of 300 μm;

[0065] (2) Take 20g of polyacrylic acid, add 80ml of ethanol and keep it sealed at 40°C for 2 hours to dissolve; then add 0.05g of magnesium chloride, 0.1g of sodium pyrrolidone hydroxy acid, 0.1g of ammonium bromide and 0.2g of polyethylene glycol-2000, Insulate at 40°C and continue to stir for 12 hours until the additives are evenly dispersed; then stand for 12 hours for defoaming;

[0066] (3) Apply the mixture obtained in step (2) evenly on the surface of the non-woven fabric, and keep it dry for 6 hours in an air blast drying oven at 80° C. to obtain a total heat exchange membrane.

[0067] The water vapor transmission rate test was carried out on the above-mentioned total heat exchange membrane, the conditions were the same as in Example 1, and the water vapor transmission rate obtained in 24 hours was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com