Carbon material used for supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of excessive use of organic chemical reagents, complex processes, and high costs, and achieve good electrochemical performance and process flow. The effect of short, high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

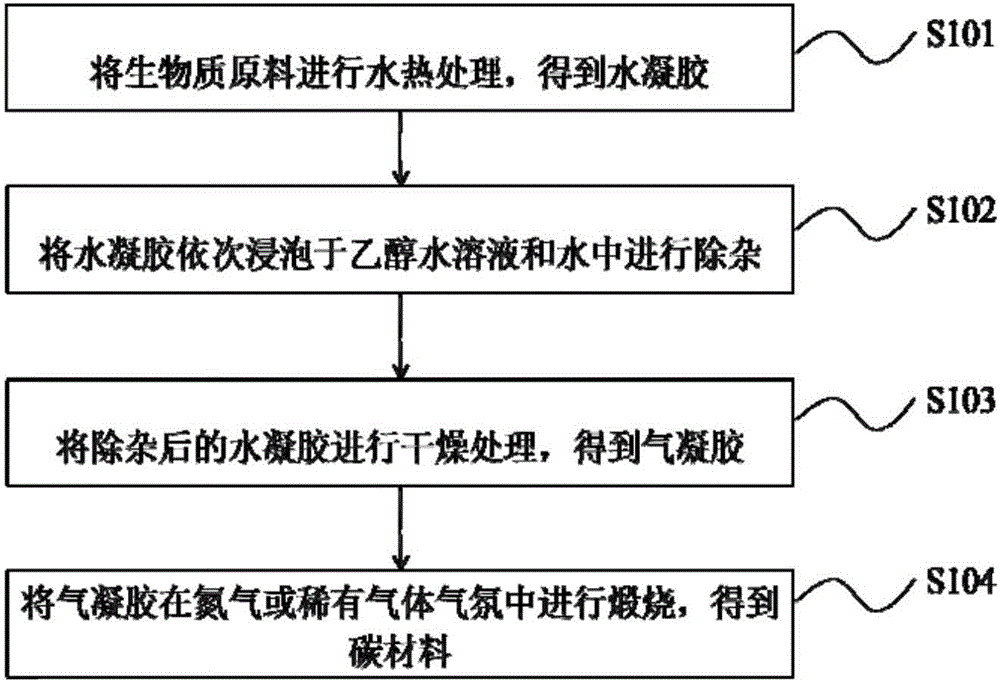

[0031] figure 1 A block diagram showing a method for preparing a carbon material provided by an embodiment of the present invention, such as figure 1 Shown, a kind of preparation method of carbon material, comprises the steps:

[0032] S101: subjecting biomass raw materials to hydrothermal treatment to obtain a hydrogel;

[0033] Specifically: Put the paste or block biomass raw materials into the reactor, which is usually lined with polytetrafluoroethylene, seal the reactor and place it in an oven at 150-300°C for 6-48 hours, then carry out hydrothermal treatment , cooling the reaction kettle after hydrothermal treatment, usually naturally cooling to room temperature, taking out the product in the kettle to obtain a hydrogel. The type of raw materials, the conditions of hydrothermal treatment, etc. all have certain influence on the performance of carbon materials. In order to further improve the electrochemical performance of carbon materials, the raw materials are preferabl...

Embodiment 1

[0042] The preparation method of the carbon material provided in this embodiment adopts the following steps:

[0043] S101: Pound the kiwi fruit into a paste, take 40ml of the paste and put it into a polytetrafluoroethylene-lined reactor with a capacity of 100ml, seal the reactor well, put it in an oven at 180°C for 24 hours, and carry out hydrothermal reaction , after the reaction kettle is naturally cooled to room temperature, the product in the kettle is taken out to obtain a massive hydrogel;

[0044] S102: Soak the block hydrogel obtained in S101 in a 50% ethanol aqueous solution to remove impurities, soak for 24 hours and then filter, then soak the block hydrogel for a second time to remove impurities, and co-immerse to remove impurities 4 times, each soaking time is 24h, to obtain the semi-purified block gel, and then soak the semi-purified block gel in deionized water, each soaking 5h, soaking 2 times in total, Obtain block hydrogel after impurity removal;

[0045] S...

Embodiment 2~7

[0049] The preparation methods of the carbon materials provided in Examples 2-7 are similar to those in Example 1, with some parameters changed, see Table 1 for details, and the parameters not listed are the same as those in Example 1.

[0050] Important parameters involved in the preparation method of the carbon material provided in Table 1 Examples 1-7

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com