Low-temperature lithium-ion battery

A lithium-ion battery, low-temperature technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as restricting use, and achieve the effect of improving specific surface area, good low-temperature discharge characteristics, and good ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

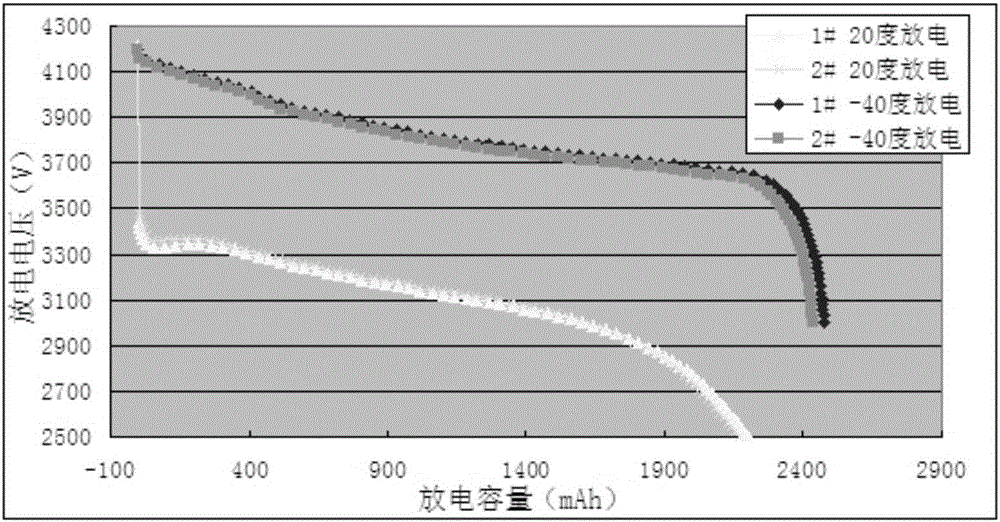

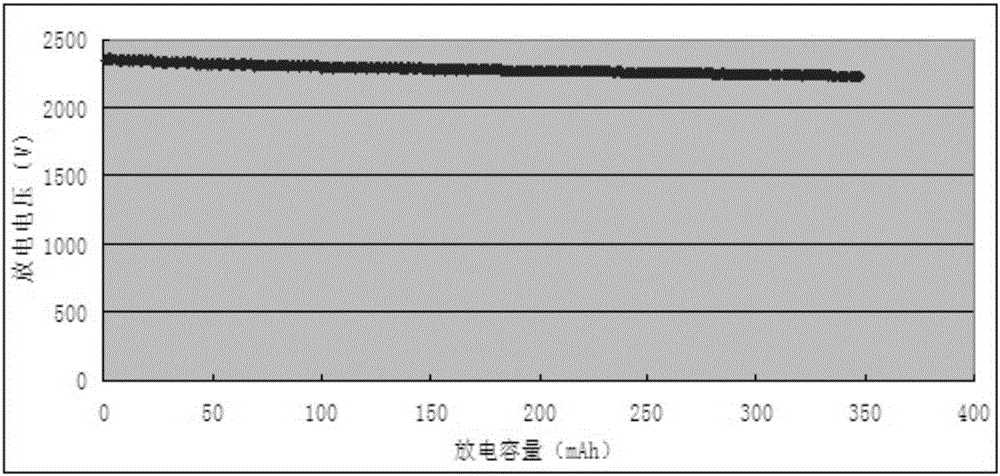

[0017] The following will describe in detail with reference to the drawings and specific embodiments.

[0018] This time, the polymer lithium-ion battery P854565-2300mAh is used for illustration and description. The battery includes a positive pole piece, a negative pole piece, a diaphragm, a low-temperature electrolyte, and an aluminum-plastic film casing. The positive pole piece includes positive active material, binder and conductive agent; the negative pole piece includes negative active material, binder and conductive agent.

[0019] In the positive pole sheet, the positive active material is lithium cobaltate, and its particle size is 2-12um, preferably 5-8um. It accounts for 85-95% by mass in the pole piece coating, 3-6% by mass of the conductive agent, and 2-3% of the total mass by the binder, and the single surface density of the positive pole piece coating is 50- 210g / ㎡, preferably 70-190g / ㎡. This example is most preferred: lithium cobaltate 93.5%, conductive agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com