Silicon-containing composite material and preparation method and application thereof

A technology of silicon composite materials and silicon particles, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of high cost and complex synthesis process, and achieve low production cost, fast preparation method, and high charge and discharge capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Preparation of phytic acid-coated silicon nanoparticles

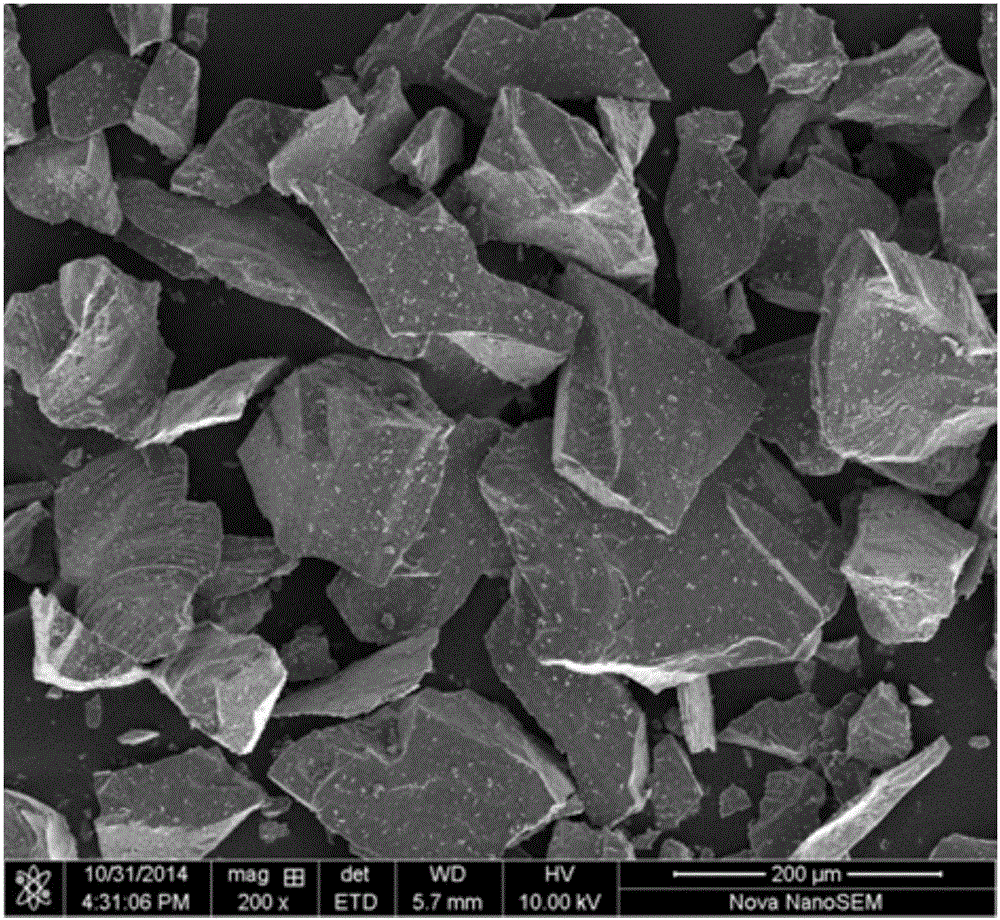

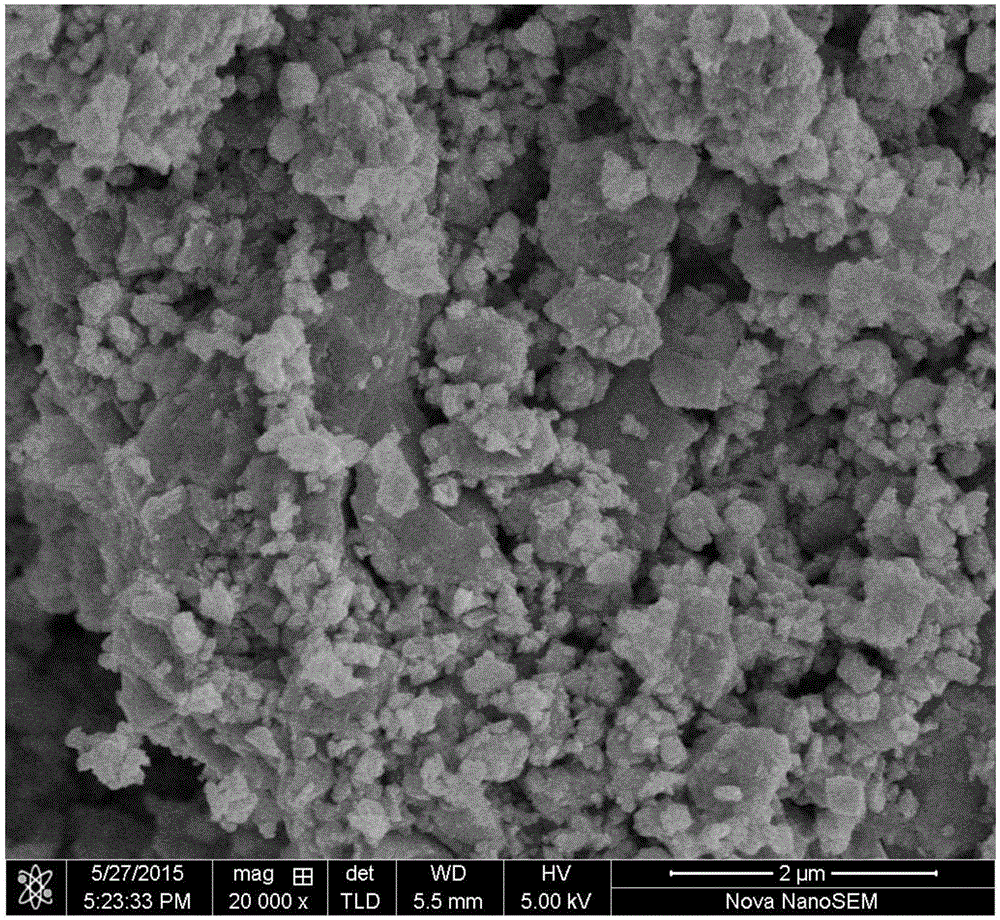

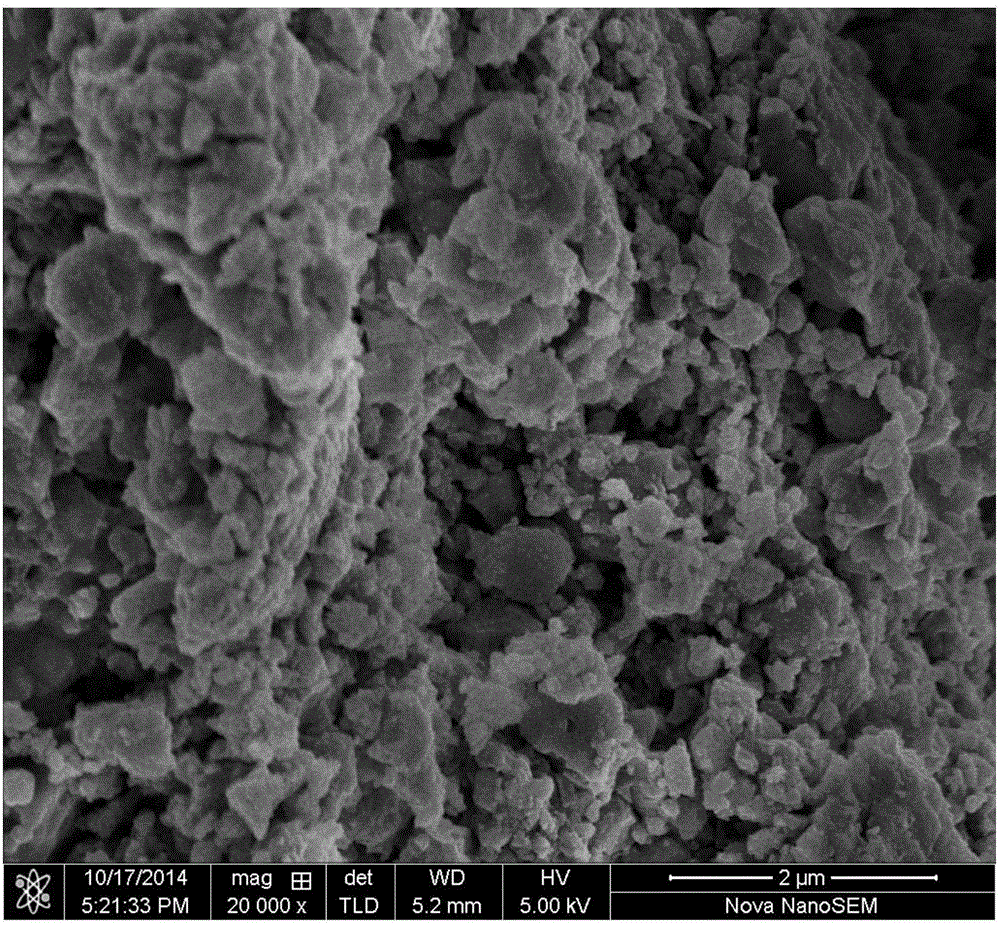

[0062] In an argon-filled glove box, commercially purchased micron-sized silicon powder (purchased from Aladdin, 40-200 mesh) and 6 stainless steel balls (two steel balls with a diameter of 14.3 mm and four steel balls with a diameter of 11.1 mm ) into a stainless steel bottle (100 mL), the mass ratio of steel balls to silicon powder is 20:1, and then use a SPEX-8000 high-energy ball mill at room temperature for 10 hours to collect the obtained silicon powder, and the grinding yield ( The ratio of powder mass after grinding to that before) is over 90%. In an argon atmosphere, mix 0.6g of ball-milled silicon powder with 0.4mL of phytic acid solution (50wt%), ball mill for 10h, and dry at 80°C for 10h under vacuum to obtain 0.88853g of silicon-phytic acid particles. The yield 98%. According to thermogravimetric analysis, the mass ratio of silicon to phytic acid in the silicon-phytic acid particles is 9:1. Beca...

Embodiment 2

[0078] According to the steps similar to Example 1, the amount of silicon powder after grinding is 0.3g, and the amount of 50wt% phytic acid solution is 0.4mL. Through thermogravimetric analysis, the mass ratio of silicon and phytic acid in silicon-phytic acid particles is 5 :1. The dosage of silicon-phytic acid particles is 6 mg, the dosage of graphene oxide is 3 mg, and the dosage of carbon nanotubes is 1 mg. The graphene used is single-layer graphene; the carbon nanotube used is single-walled carbon nanotube. The time for ball milling is 6 hours, the time for the first ultrasonic wave is 12 minutes, and the time for the second ultrasonic wave is 10 minutes.

Embodiment 3

[0080] According to the steps similar to Example 1, the amount of silicon powder after grinding is 2.0g, and the amount of 50wt% phytic acid solution is 0.4mL. Through thermogravimetric analysis, the mass ratio of silicon and phytic acid in the silicon-phytic acid particles is 20 :1. The amount of silicon-phytic acid particles is 78 mg, the amount of graphene oxide is 20 mg, and the amount of carbon nanotubes is 1 mg. The graphene used is multilayer graphene; the carbon nanotubes used are double-walled carbon nanotubes. The time for ball milling is 25 hours, the time for the first ultrasonic wave is 50 minutes, and the time for the second ultrasonic wave is 55 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com