Manufacturing technique of oxidized hydroxypropyl starch

A technology for oxidizing hydroxypropyl group and a production process, applied in the field of edible auxiliary materials, can solve problems such as unfavorable mass production, environmental pollution, complicated process, etc., and achieve the effects of being beneficial to mass production, reducing pollution and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

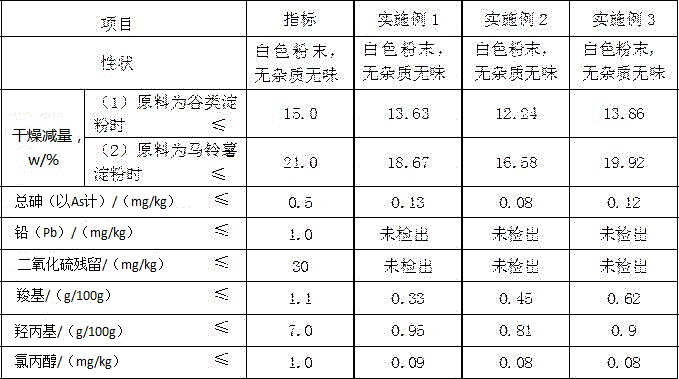

Examples

Embodiment 1

[0021] A kind of preparation technology of oxidized hydroxypropyl starch, concrete steps are as follows:

[0022] (1) Dilute and dissolve: add 2% hydrogen peroxide solution with a mass concentration of 50% and 15% water into a stainless steel dissolution tank at the same time, stir for 25-35 minutes to dissolve the hydrogen peroxide solution, and obtain a diluted and dissolved hydrogen peroxide solution;

[0023] (2) Mixing reaction: put 83% hydroxypropyl starch into the mixer, turn on the stirring function, add the hydrogen peroxide solution diluted and dissolved in step (1) into the mixer at a uniform speed, and finish adding in 2 hours. Stir while adding hydrogen peroxide solution, and stir to form a microstrip wet powder;

[0024] (3) Heating: Turn on the hot water in the interlayer of the mixer, keep the temperature of the hot water at 60°C, raise the temperature of the powder in step (2) to 50°C, and keep it warm for 2 hours;

Embodiment 2

[0030] A kind of preparation technology of oxidized hydroxypropyl starch, concrete steps are as follows:

[0031] (1) Dilute and dissolve: add 3% hydrogen peroxide solution with a mass concentration of 50% and 16% water into a stainless steel dissolution tank at the same time, stir for 25-35 minutes to dissolve the hydrogen peroxide solution, and obtain a diluted and dissolved hydrogen peroxide solution;

[0032] (2) Mixing reaction: put 81% hydroxypropyl starch into the mixer, turn on the stirring function, add the hydrogen peroxide solution diluted and dissolved in step (1) into the mixer at a uniform speed, and finish adding in 2.5 hours. Stir while adding hydrogen peroxide solution, and stir to form a microstrip wet powder;

[0033] (3) Heating: Turn on the hot water in the interlayer of the mixer, keep the temperature of the hot water at 60°C, raise the temperature of the powder in step (2) to 50°C, and keep it warm for 2.5 hours;

Embodiment 3

[0039] A kind of preparation technology of oxidized hydroxypropyl starch, concrete steps are as follows:

[0040] (1) Dilute and dissolve: add 2% hydrogen peroxide solution with a mass concentration percentage of 50% and 18% water into a stainless steel dissolution tank at the same time, stir for 25-35 minutes to dissolve the hydrogen peroxide solution, and obtain a diluted and dissolved hydrogen peroxide solution;

[0041] (2) Mixing reaction: put 80% hydroxypropyl starch into the mixer, turn on the stirring function, add the hydrogen peroxide solution diluted and dissolved in step (1) into the mixer at a uniform speed, and add it for 2-3 hours. When finished, stir while adding hydrogen peroxide solution, and stir to form a microstrip wet powder;

[0042] (3) Heating: Turn on the hot water in the interlayer of the mixer, keep the temperature of the hot water at 60°C, raise the temperature of the powder in step (2) to 50°C, and keep it warm for 3 hours;

[0043] (4) Drying: d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com