Preparation method of polybenzimidazole/modified polyepichlorohydrin composite anion-exchange membrane

A polyepichlorohydrin, anion exchange membrane technology, applied in fuel cells, electrochemical generators, electrical components, etc. Pollution and other problems, to achieve good mechanical properties and chemical stability, reduce the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

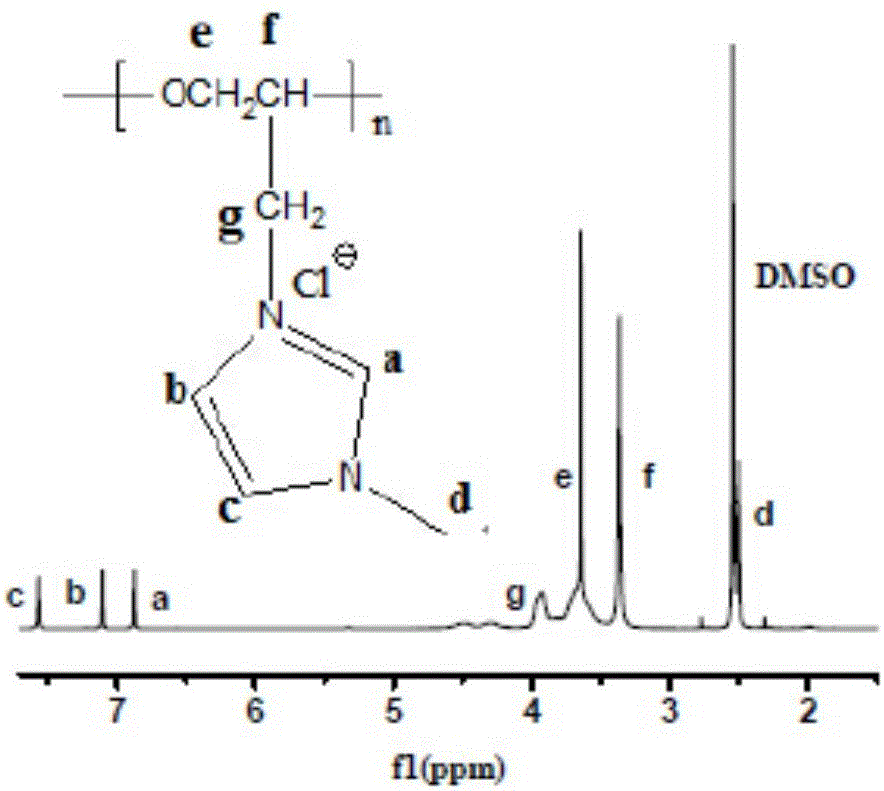

Method used

Image

Examples

Embodiment 1

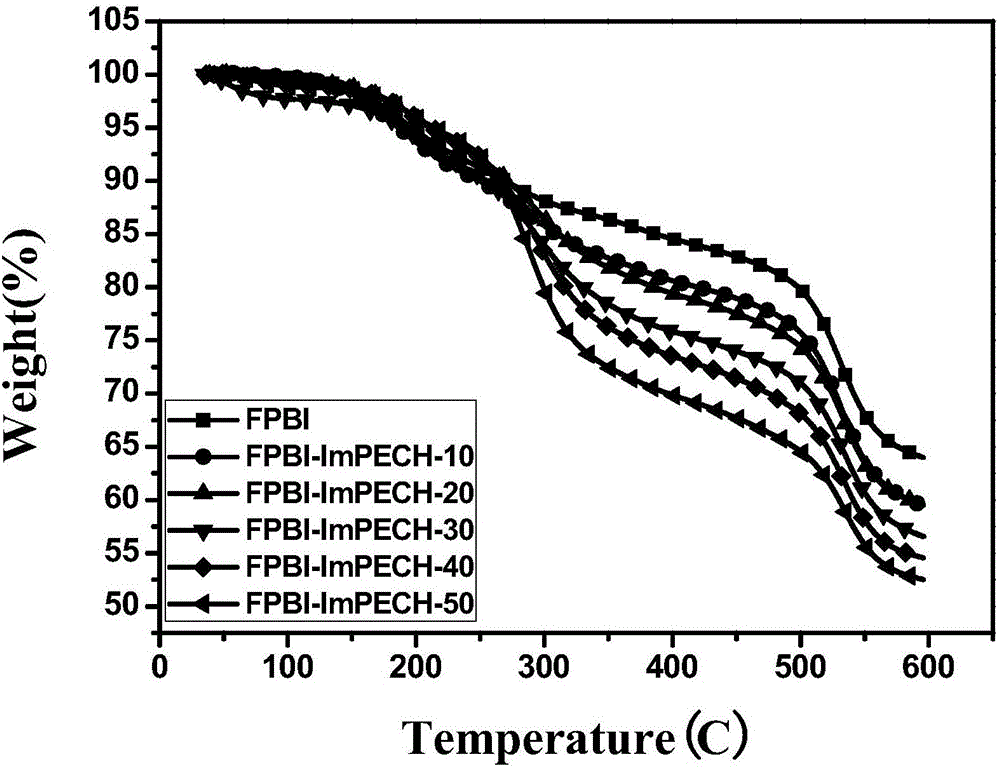

[0023] Preparation of 10% modified polyepichlorohydrin doped PBI composite anion exchange membrane

[0024] (1) Preparation of fluorine-containing polybenzimidazole (PBI) solution

[0025] Stir 27g of polyphosphoric acid PPA at 140°C under the protection of nitrogen until the solid is completely dissolved and deoxidized into a colorless transparent solution and cooled to room temperature; under the protection of nitrogen, add 2.14g of 3,3'-diaminobiphenyl Diamine and 3.92g of 2,2-bis(4-carboxyphenyl)hexafluoropropane, raise the reaction temperature to 100°C, 120°C, and 140°C, and react at each temperature for 12h, 12h, and 6h respectively; After cooling, pour the reaction system into deionized water to precipitate a brown filamentary polymer, soak or wash the polymer to remove excess acid, and obtain fluorine-containing polybenzimidazole polymer after vacuum drying; finally, the obtained fluorine-containing polyphenylene The imidazole polymer is added to dimethyl sulfoxide (D...

Embodiment 2

[0032] Preparation of 20% modified polyepichlorohydrin doped PBI composite anion exchange membrane

[0033] In the control step (3), the mass ratio of modified polyepichlorohydrin to fluorine-containing polybenzimidazole is 2:8, and the rest of the operations are the same as in Example 1.

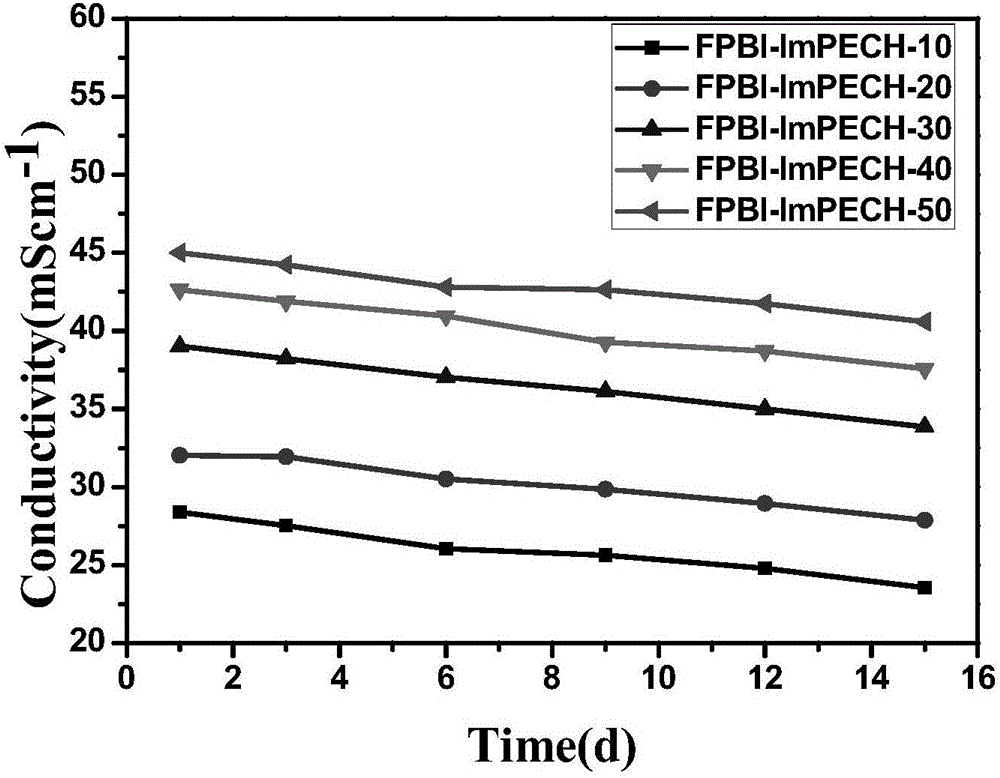

[0034] The ion conductivity of the anion exchange membrane obtained in this example at room temperature is: 32.04mS cm -1 ; The ionic conductivity at 80°C is: 40.21mS·cm -1 ; Tensile strength: 35.44MPa; Young's modulus: 856.76MPa; Elongation at break: 6.033%.

Embodiment 3

[0036] Preparation of 30% modified polyepichlorohydrin doped PBI composite anion exchange membrane

[0037] In the control step (3), the mass ratio of modified polyepichlorohydrin to fluorine-containing polybenzimidazole is 3:7, and the rest of the operations are the same as in Example 1.

[0038] The ion conductivity of the anion exchange membrane obtained in this example at room temperature is: 39.01mS cm -1 ; The ionic conductivity at 80°C is: 45.74mS·cm -1 ; Tensile strength: 30.29MPa; Young's modulus: 731.67MPa; Elongation at break: 7.370%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com