Preparation method and application of oil resistant rubber applied under railroad switch

A technology of oil resistance and turnout, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of oil resistance, oil absorption rate, corrosion resistance and stiffness, do not meet the test standards, low compression characteristics, etc., and achieve physical performance Stable indicators, saving mechanized production, and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 Preparation process of oil-resistant rubber backing plate for railway turnout

[0067] 1. Weigh each raw material component according to the following components:

[0068] (1) aniseed

[0069] Nitrile rubber N41: 40000g±100g

[0070] (2) middle material

[0071]

[0072] (3) small material

[0073]

[0074]

[0075] 2. Prepare oil-resistant rubber backing plates for railway turnouts according to the following steps:

[0076] 1) Put the prepared raw rubber into the kneader for mastication, the mastication temperature is controlled at 60-80°C, and the time is controlled at 1-5 minutes;

[0077] 2) Add carbon black and semi-reinforcing agent to the plasticized raw rubber for masterbatching. The temperature of the masterbatch is controlled at 60-80°C and the time is controlled at 5-7 minutes;

[0078] 3) Put the raw rubber after the master batch into the open mill, and after mixing the rubber left and right, roll up and evenly, adjust the roller di...

Embodiment 2

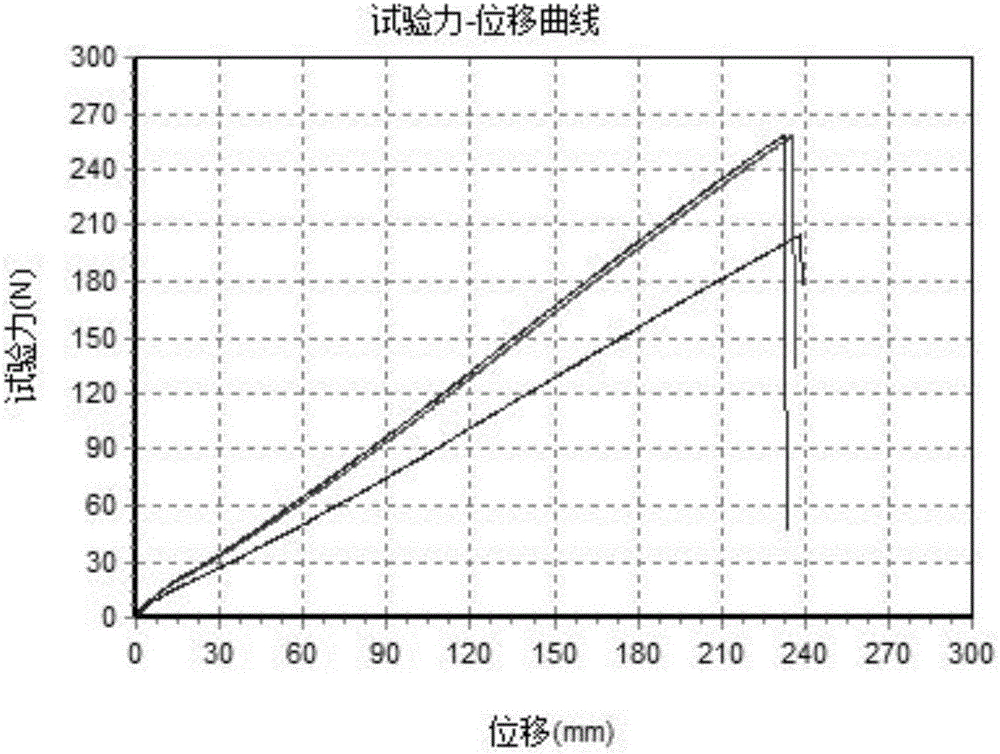

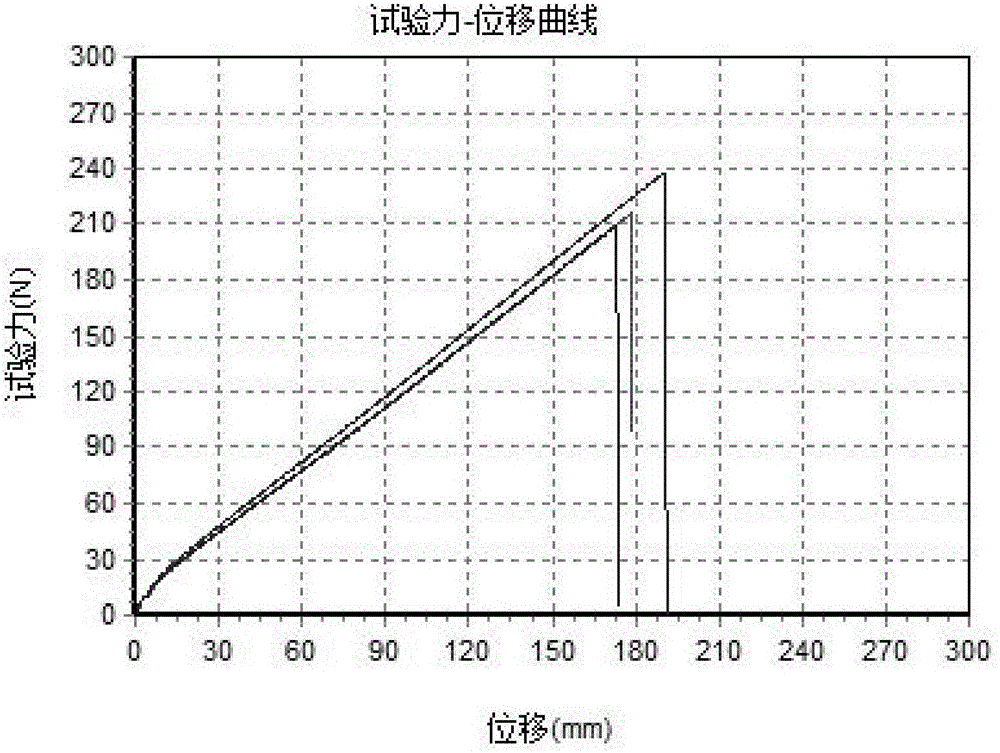

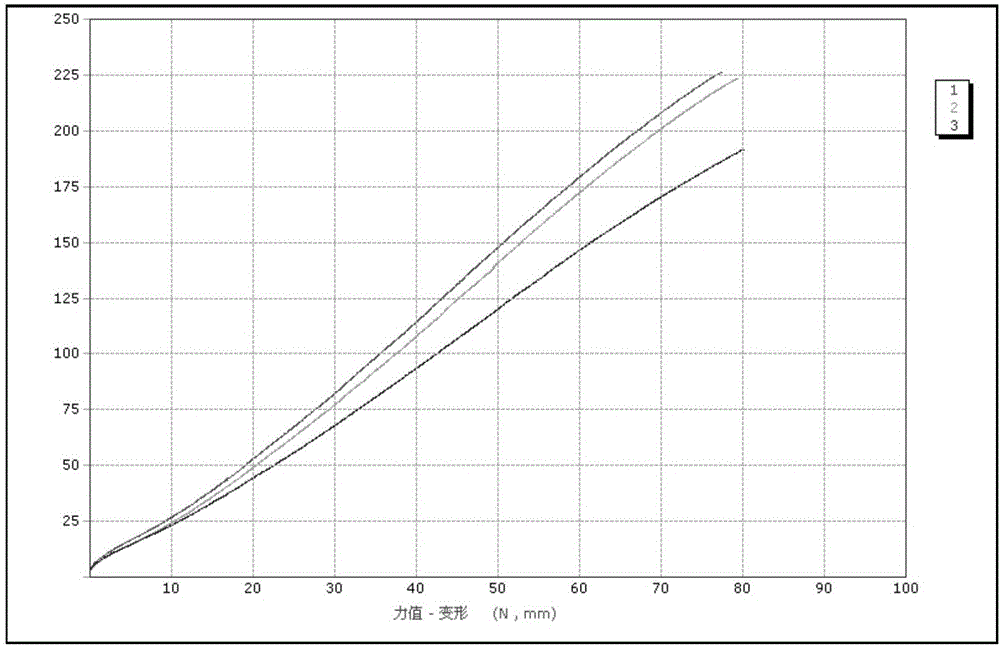

[0083] Example 2 Performance test of the oil-resistant rubber backing plate used under the railway turnout of the present invention

[0084] (1) Inspection equipment:

[0085] Shore A Hardness Tester

[0086] WDL multifunctional electronic tensile testing machine

[0087] ZC36 Ultra High Resistance Meter

[0088] 401-A aging test chamber

[0089] JDL-4018 Low Temperature Brittleness Tester

[0090] MH-74 Abrasion Testing Machine

[0091] digital caliper

[0092] (2) Oil absorption test

[0093] 1. Oil absorption test method:

[0094] The oil-resistant rubber backing plate product under the railway turnout obtained in Example 1 is randomly selected as a sample for inspection.

[0095] 1) Take 3 samples from each backing plate, and mark them on the samples. The quality change sample is type I: a rectangle of 25mm×50mm, and the thickness of the sample is 2.0mm±0.2mm. Measure the weight of the 3 samples. weight.

[0096] 2) The test medium is 46# engine oil.

[0097] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com