Method for extracting lead through electrolyzing recycled waste lead storage battery lead plaster by ionic liquid

A waste lead storage battery and ionic liquid technology, applied in the field of non-ferrous metal metallurgy, can solve the problems of difficult-to-scale industrial promotion and application, complex lead paste pretreatment, strong electrolyte corrosion, etc., to reduce equipment corrosion, strong activity, and green recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

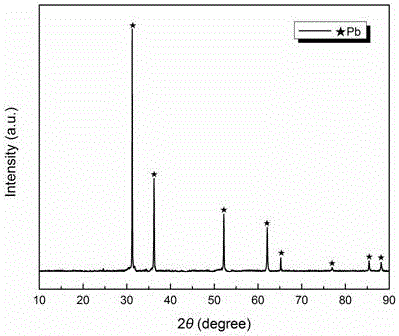

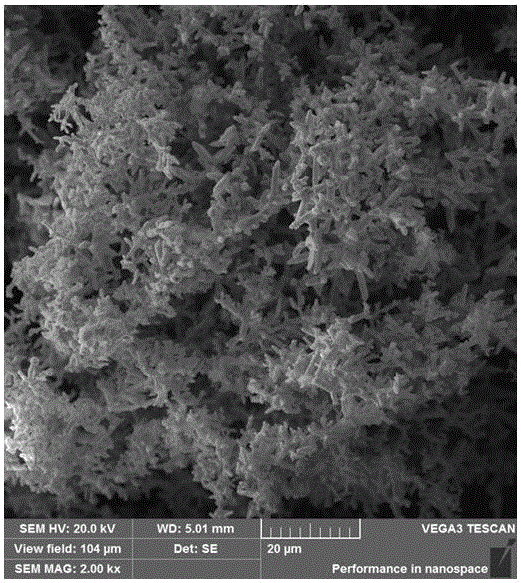

Image

Examples

Embodiment 1

[0019] The method for extracting lead from waste lead storage battery lead plaster by electrolysis of the ionic liquid, its specific steps are as follows:

[0020] (1) Firstly, the waste lead battery lead paste powder (the lead content of the waste lead battery lead paste powder is 78.54% and the following mass percentage of impurities S: O=1.59%: 8.74% is mixed at a temperature of 30°C. The particle size of waste lead battery lead paste powder is 150 μm, and the amount of waste lead battery lead paste powder is 0.01mol / L) is dissolved in ionic liquid to obtain ionic liquid electrolyte, wherein the ionic liquid is a deep eutectic solvent (under an inert atmosphere, Mix the quaternary ammonium salt and the polyol according to the molar ratio of 1:2, and mix them evenly at a temperature of 90°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salt is choline chloride, and the polyol is ethyl diol);

[0021] (2) In an inert atmosphere, ...

Embodiment 2

[0023] The method for extracting lead from waste lead storage battery lead plaster by electrolysis of the ionic liquid, its specific steps are as follows:

[0024] (1) Firstly, the lead paste powder of waste lead storage battery (the lead content of the lead paste powder of waste lead storage battery is 70.08% and the impurity S in the following mass percentages: O=1.59%: 8.74% is firstly mixed at a temperature of 85°C, The particle size of waste lead battery lead paste powder is 40 μm, and the amount of waste lead battery lead paste powder is 0.1mol / L) is dissolved in ionic liquid to obtain ionic liquid electrolyte, wherein the ionic liquid is a deep eutectic solvent (under an inert atmosphere, Mix the quaternary ammonium salt and polyol according to the molar ratio of 3:5, and mix evenly at a temperature of 70°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salt is tetrabutylammonium chloride, polyol for glycerol);

[0025] (2) ...

Embodiment 3

[0027] The method for extracting lead from waste lead storage battery lead plaster by electrolysis of the ionic liquid, its specific steps are as follows:

[0028] (1) Firstly, the lead paste powder of waste lead storage battery (the lead content of the waste lead storage battery lead paste powder is 70.08% and also contains the following mass percentage of impurities S: O=1.59%: 8.74% at a temperature of 70°C, The particle size of waste lead battery lead paste powder is 75 μm, and the amount of waste lead battery lead paste powder is 0.05mol / L) is dissolved in ionic liquid to obtain ionic liquid electrolyte, wherein the ionic liquid is a deep eutectic solvent (under an inert atmosphere, Mix the quaternary ammonium salt and polyol according to the molar ratio of 1:2, and mix evenly at a temperature of 60°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salt is tetramethylammonium chloride, polyol for xylitol);

[0029] (2) Under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com