Automatic underwater silt remover

A desilting machine and automatic technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as high cost, easy to damage hard soil layers, and damage the environment, and achieve The effect of high work efficiency, low operation difficulty and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

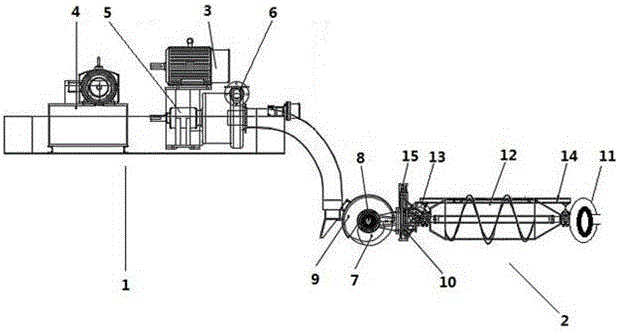

[0084] Embodiment one: figure 1 As shown, the underwater automatic desilting machine is composed of two parts, the above water part 1 and the underwater part 2. The above water part 1 and the underwater part 2 are connected extensibly by mud pipes, hydraulic pipes and hoisting ropes. The above water part 1 includes a mud pump 3, a hydraulic station 4, a small air pump 5, a generator (not shown in the figure), a winch 6 and a control system, and the underwater part 2 includes a collection transfer device 7, a collection motor 8 , Collecting shield 9, collecting hoisting device 10, collector 11 and propeller 12, said collector 11 is hinged with propeller 12, and said propeller 12 adopts hollow structure.

[0085] The propeller 12 is provided with a counterweight device 13, and the counterweight device 13 can drive the underwater part to float up and down in the water. It can realize dredging for different geographical environments, and it is convenient to climb and descend slop...

Embodiment 2

[0090] Embodiment two: figure 1 As shown, the underwater automatic desilting machine is composed of two parts, the above water part 1 and the underwater part 2. The above water part 1 and the underwater part 2 are connected extensibly by mud pipes, hydraulic pipes and hoisting ropes. The above water part 1 includes a mud pump 3, a hydraulic station 4, a small air pump 5, a generator (not shown in the figure), a winch 6 and a control system, and the underwater part 2 includes a collection transfer device 7, a collection motor 8 , Collecting shield 9, collecting hoisting device 10, collector 11 and propeller 12, said collector 11 is hinged with propeller 12, and said propeller 12 adopts hollow structure.

[0091] The propeller 12 is provided with a counterweight device 13, and the counterweight device 13 can drive the underwater part to float up and down in the water. It can realize dredging for different geographical environments, and it is convenient to climb and descend slop...

Embodiment 3

[0096] Embodiment three: figure 1 As shown, the underwater automatic desilting machine is composed of two parts, the above water part 1 and the underwater part 2. The above water part 1 and the underwater part 2 are connected extensibly by mud pipes, hydraulic pipes and hoisting ropes. The above water part 1 includes a mud pump 3, a hydraulic station 4, a small air pump 5, a generator (not shown in the figure), a winch 6 and a control system, and the underwater part 2 includes a collection transfer device 7, a collection motor 8 , Collecting shield 9, collecting hoisting device 10, collector 11 and propeller 12, said collector 11 is hinged with propeller 12, and said propeller 12 adopts hollow structure.

[0097] The propeller 12 is provided with a counterweight device 13, and the counterweight device 13 can drive the underwater part to float up and down in the water. It can realize dredging for different geographical environments, and it is convenient to climb and descend sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com