Preparation method of three-dimensional pd-ni nanowire array catalyst for electroreduction of hydrogen peroxide

A technology of nanowire array and hydrogen peroxide, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of slow cathode reaction kinetics, etc., and achieve the effect of solving poor cathode activity, reducing usage and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better illustrate the effect of the process of the present invention, specific examples are used below to illustrate.

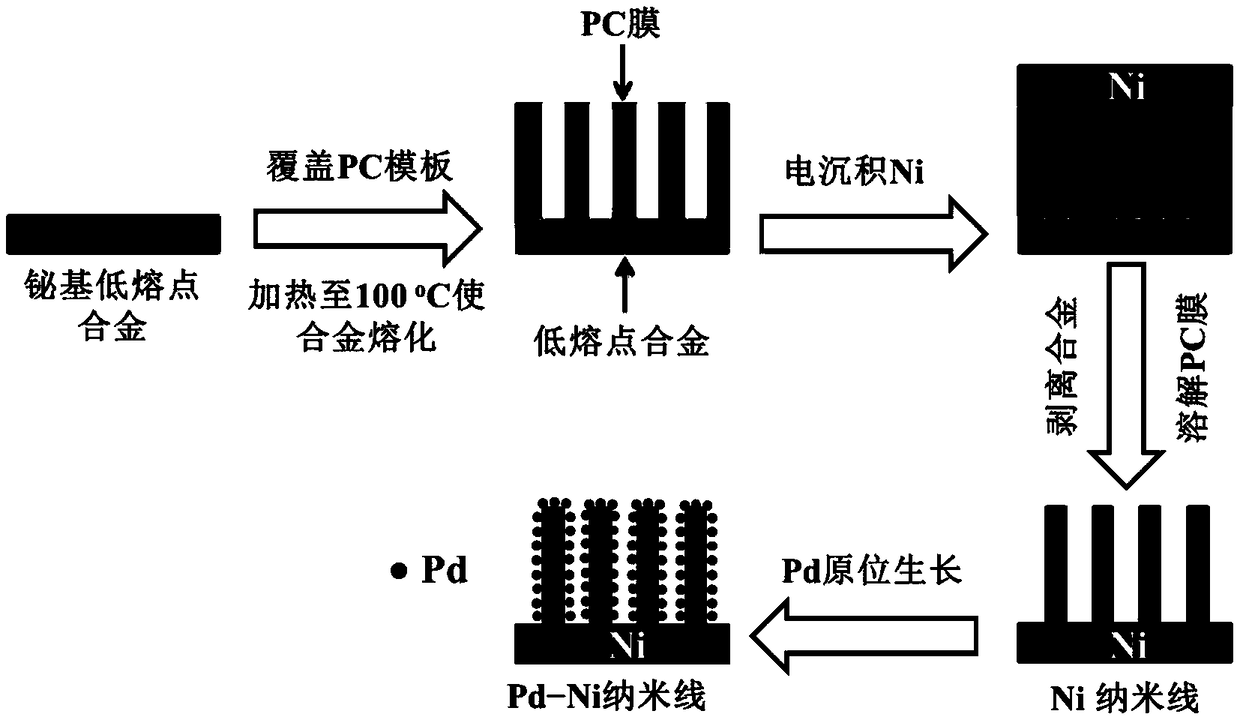

[0023] (1) In a constant temperature oven at 100°C, brush the liquid low-melting bismuth-based alloy (melting point: 65°C) on the surface of the track-etched polycarbonate film (PC template), and after the alloy is cooled, it is mixed with The PC template constitutes a composite electrode (PC film-alloy electrode).

[0024] (2) Take 80mL of electrolyte solution in a 100mL beaker, use the composite electrode (PC film-alloy electrode) as the working electrode, and electrolyze the nickel sheet (4.0×4.0cm 2 ) is the auxiliary electrode, and the saturated Ag / AgCl electrode is the reference electrode, forming a three-electrode system for electrochemical deposition. The electrodeposition process is carried out in a constant temperature water bath at 55 °C and a stirring speed of 150 rpm. After applying a constant cathodic current (-196mA), Nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com